09 gas requirements, 10 gas applications, Gas requirements -5 – Tweco 100 Auto-Cut User Manual

Page 31: Gas applications -5

Manual 0-4764

2-5 SPECIFICATIONS

2.09 Gas Requirements

The customer will provide all gases and pressure regulators. Gases must be of high quality. Pressure regulators

shall be equipped with stainless-steel diaphragms and installed as close as possible to the Gas Console. NOTE:

The chart includes gases which may not be used in all applications.

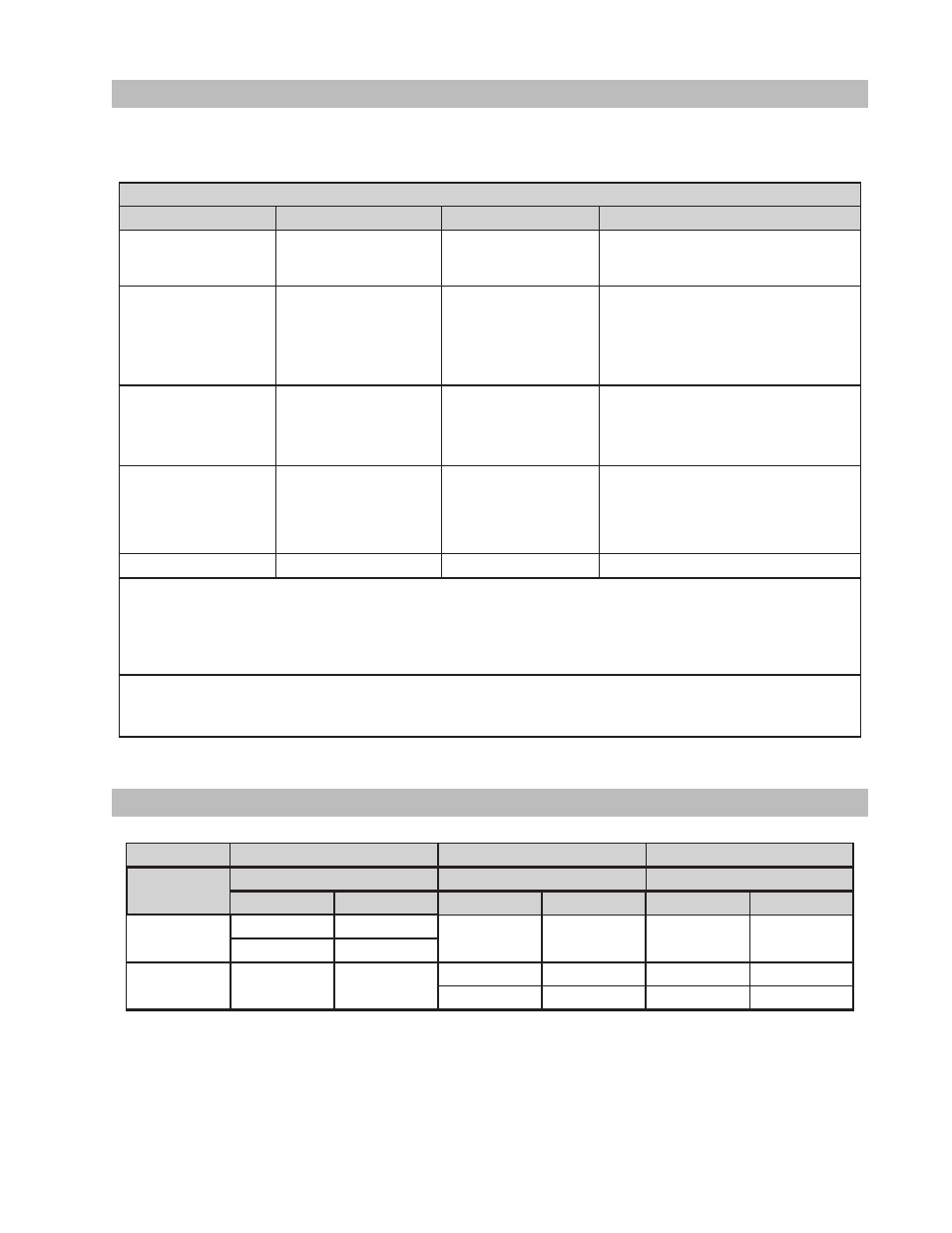

Auto-Cut 200 BASIC Power Supply: Gas Pressures, Flows, and Quality Requirements

Gas

Quality

Minimum Pressure

Flow

O

2

(Oxygen)

99.5% Purity

(Liquid recommended)

120 psi

8.3 bar / 827 kPa

200 scfh (5700 l/h)

N

2

(Nitrogen)

99.5% Purity

(Liquid recommended)

<1000 ppm O

2

, <32

ppm H

2

O)

120 psi

8.3 bar / 827 kPa

300 scfh (8496 l/h)

Compressed

Air

Clean, Dry,

Free of Oil (see Note 1)

90 psi

6.2 bar / 621 kPa

400 scfh (11327 l/h)

H35 (Argon-

Hydrogen)

H35 = 35% Hydrogen,

65% Argon

99.995% Purity

(gas recommended)

120 psi

8.3 bar / 827 kPa

200 scfh (5664 l/h)

H

2

O (Water)

See Note 2

50 psi (3.5 bar)

10 gph (38 lph)

Note 1: The air source must be adequately filtered to remove all oil or grease. Oil or grease

contamination from compressed or bottled air can cause fires in conjunction with oxygen.

For filtering, a coalescing filter able to filter to 0.01 microns should be placed as close as

possible to the gas inlets on the Gas Control Module.

Note 2: The tap water source does not need to be deionized, but in water systems with extremely high

mineral content a water softener is recommended. Tap water with high levels of particulate matter must be

filtered.

2.10 Gas Applications

MATERIAL

MILD STEEL

STAINLESS STEEL

ALUMINUM

OPERATION

GAS TYPE

GAS TYPE

GAS TYPE

PLASMA

SHIELD

PLASMA

SHIELD

PLASMA

SHIELD

55 A CUT

Air

Air

Air

Air

Air

Air

O

2

Air

100 A CUT

Air

Air

Air

Air

Air

Air

O

2

Air

N

2

H

2

0

N

2

H

2

0