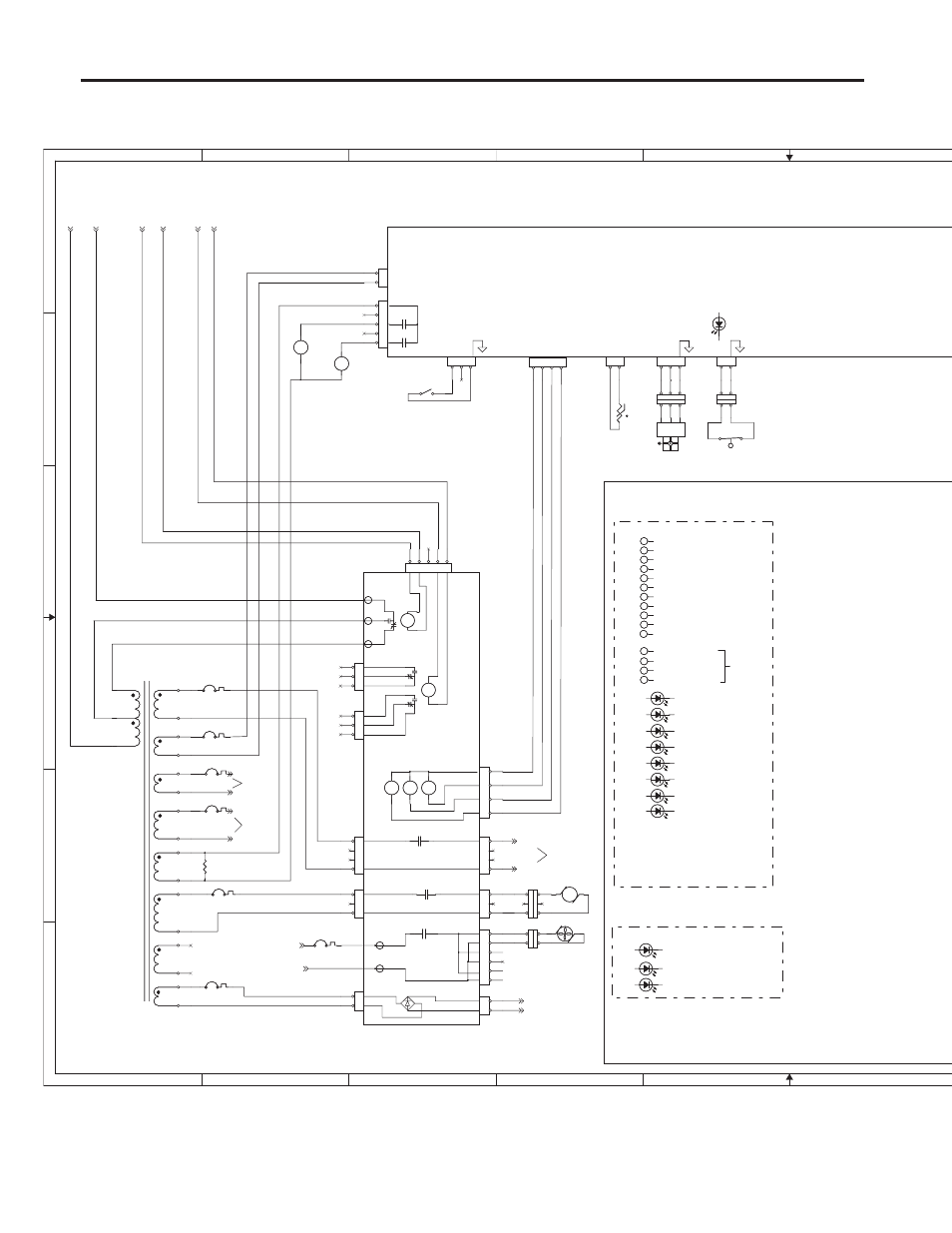

Appendix 9: schematic, ce 400v, chopper pilot cont, Thermal dynamics, Ccm module – Tweco 100 Auto-Cut User Manual

Page 134: I/o pcb cpu pcb

APPENDIX A-26

Manual 0-4764

APPENDIX 9: SCHEMATIC, CE 400V, CHOPPER PILOT CONT.

Art # A-06997_AD

Art # A-06997_AD

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

A

A

B

B

C

C

D

D

E

E

F

F

400

AC120 @ 1A

PLASMA ENABLE

AC13V @ 2A

/PUMP

+15

V

+15V

400

/FAN

200-not used

/RAS

COM

200

PRESS OK (GCM 1000)

24VAC

400

24 VAC RE

T

PLASMA ENABLE

+15V

/ AC

/ TEMP

/ STATUS

/ DC

/ GAS - COOLANT

COM

AC200V @ 3A

POT HI (GCM1000)

200

POT WIPER (GCM1000)

POT LOW (GCM 1000)

+15V

- ARC V

- ARC V

0V-A (24V ret)

WORK

To PCB7 CN2-

1

DC 15V

DC 0V

AC120V-GCM

0V-B (120V ret)

To PCB7 CN2-

2

AC120V-RAS

0V-RAS (120V ret)

To PCB7 CN2-

4

0V-A (24V ret)

To PCB7 CN2-

5

NEG ARC VOLTS

To PCB7 TB

3

0V-RAS

AC120V-RAS

FAN + (24 VDC)

NEG ARC VOLT

S

AC24V-GCM

DC 15V

AC24V-GCM

DC 0V

0V-A (24V ret)

AC120V-GCM

0V-B (120V ret)

FAN - (24 VDC)

PILOT (TIP) VOLT

S

0V-B (120V ret)

WORK

AC24V-GCM

AC120V-GCM

To T1 PRI -

0

DWG No:

Sheet

of

Supersedes

Scale

Date:

Drawn:

References

Date

By

Revisions

Rev

PCB No:

Assy No:

Information Proprietary to THERMAL DYNAMICS CORPORATION.

Not For Release, Reproduction, or Distribution without Written Consent.

NOTE: UNLESS OTHERWISE SPECIFIED -

1. RESISTOR VALUES ARE EXPRESSED IN OHMS, 1/4W 5%.

2. CAPACITOR VALUES ARE EXPRESSED IN MICROFARADS (uF).

Chk: App:

TITLE:

Last Modified:

Size

SCHEMATIC,

Thermal

Dynamics

AA

42X1211

Friday, September 25, 2009

2

2

Industrial Park #2

West Lebanon NH 03784

603-298-5711

100A Power Supply 400V CE (Chopper)

Tuesday, October 03, 2006

08:11:44

Thermal Dynamics

D

DWG No:

Sheet

of

Supersedes

Scale

Date:

Drawn:

References

Date

By

Revisions

Rev

PCB No:

Assy No:

Information Proprietary to THERMAL DYNAMICS CORPORATION.

Not For Release, Reproduction, or Distribution without Written Consent.

NOTE: UNLESS OTHERWISE SPECIFIED -

1. RESISTOR VALUES ARE EXPRESSED IN OHMS, 1/4W 5%.

2. CAPACITOR VALUES ARE EXPRESSED IN MICROFARADS (uF).

Chk: App:

TITLE:

Last Modified:

Size

SCHEMATIC,

Thermal

Dynamics

AA

42X1211

Friday, September 25, 2009

2

2

Industrial Park #2

West Lebanon NH 03784

603-298-5711

100A Power Supply 400V CE (Chopper)

Tuesday, October 03, 2006

08:11:44

Thermal Dynamics

D

DWG No:

Sheet

of

Supersedes

Scale

Date:

Drawn:

References

Date

By

Revisions

Rev

PCB No:

Assy No:

Information Proprietary to THERMAL DYNAMICS CORPORATION.

Not For Release, Reproduction, or Distribution without Written Consent.

NOTE: UNLESS OTHERWISE SPECIFIED -

1. RESISTOR VALUES ARE EXPRESSED IN OHMS, 1/4W 5%.

2. CAPACITOR VALUES ARE EXPRESSED IN MICROFARADS (uF).

Chk: App:

TITLE:

Last Modified:

Size

SCHEMATIC,

Thermal

Dynamics

AA

42X1211

Friday, September 25, 2009

2

2

Industrial Park #2

West Lebanon NH 03784

603-298-5711

100A Power Supply 400V CE (Chopper)

Tuesday, October 03, 2006

08:11:44

Thermal Dynamics

D

DAT

ECO-B402 DAT 2/26/07

AB ECO-B448 DAT 4/13/07

AC ECO-B646 GAC 10/31/07

AD ECO-B1391

DAT 4-24-09

DAT

AE

(F1 Sht 1)

(F1 Sht 1)

PILOT

CONTACTOR

(E2)

INPUT

CONTACTOR

MOMENTARY START / STOP

START / STOP

* REMOTE MARKING -

STOP

START

(D9, A10)

PILOT (TIP) VOLTAGE

COOLANT TEMP

(ON COOLANT

RETURN)

* Only in CCM w/

19X2634 I/O PCB.

Remote Marking

only for DFC 3000

(not isolated)

ISOLATED COMM

+16 to +18VDC

Rx-

Tx+

Rx+

Tx-

CCM MODULE

Signal & GND

Isolated from

Plasma Supply

FROM CN18 PCB3 sht 1

INTERNAL TERMINAL

STRIP TB3

KEY PLUG

+15VDC_ISO

TB1

TB2

(C9, sht 1)

-15VDC_ISO

+

-

RS 485 (2 wire)

uses Tx+ & Tx- only

(used for TSC 3000)

Signal - Basic ID

Used to identify

GCM 1000 present

RIBBON CABLE

TEST SOCKET

(F1 Sht 1)

RS 422 (4 wire)

connect TX+ to RX+

of CNC, Tx- to Rx-

of CNC

(F1 Sht 1)

(F2 Sht 1)

DIVIDED ARC V +

(E2)

(E2)

ISOLATED

VOLTAGES

(D9, A10)

(F2 Sht 1)

DIVIDED ARC V -

REMOTE ANALOG CURRENT CONTROL -

REMOTE ANALOG CURRENT CONTROL +

JUMPER IN

REMOTE

HMI

** RS 485 / 422

on CPU board

19X2554 only.

(A9, sht1

)

(B9, sht1

)

(C9, sht1

)

NEG ARC VOLTS

SW6 - OK to MOVE CONTACTS / VOLTS

SW11 - ANALOG CURRENT SELECT

"B" DEFAULT, "A" REMOTE

TB3

KEY PLUG

Was 7 pin

changed to

14 pin in 2009

SW12 - DIVIDED ARC V RATIO SELECT

(E4)

SW13 - FACTORY ONLY

PCB7 WK-5628

RELAY PCB

(F4)

CIRCUIT COMM (GND)

CN11 34 CKT

CN10 26 CKT

(C9)

PCB 5 WK-5602 (partial) INTERFACE PCB

START / STOP

DIVIDED ARC VOLTS

PILOT ON

OUTPUT

PILOT DEM to PS

ANALOG DEM to CPU

REMOTE ANALOG

CURRENT CONTROL

* OK2

Iso

J36 34 CKT

PCB6 DISPLAY

WK-5603

JUMPER

for 2 WIRE

(RS485 only)

wire to A & B

4W

4W

2W

JUMPER

for 4 WIRE

uses

TX+, TX-

RX+, RX-

J35 26 CKT

J14

J14

2W

SW14

SW14 - LINE

TERMINATION

normally on

(refer to manual)

* OK2

CUT DEM to PS

RIBBON CABLE

5

9

8

76

1

2

3

4

SW10-ADDRESS

normally 0

(refer to

manual)

0

TEST SOCKET

HOLD START -

HOLD START +

(A9, sht 1)

UNDIVIDED ARC VOLTS

FOR HEIGHT CONTROLS

* +10VDC @ 10 ma.(for CC pot high)

OK TO MOVE

GND

GND

& CNC COMM

PREFLOW ON -

PREFLOW ON +

PLASMA ENABLE

24 VAC @ 1A

120 VAC @ 100ma.

(Not in all units)

OK to MOVE -

POWER SUPPLY

REAR PANEL

E-STOP -

E-STOP +

TO AC INDICATOR (on PCB6)

* REMOTE MARKING +

29-41 VDC

RIBBON CABLE SIGNALS

/ = active low digital signal

CN10-J35 - 26 Ckt Ribbon Cable

2-Cut Demand

4-Pilot Demand

6-/ Start

7-/ Start2

9-/ Pilot Enable

10-/ HF Enable

12-/ Pump Enable

13-/ Fan Enable

15-/ DC Indicator

16-/ Over Temperature Indicator

18-/ Gas-Coolant OK Indicator

19-/ Status Lamp

CN11-J36 - 34 Ckt Ribbon Cable

1- Output Current Signal

3- / Arc Transferred (CSR)

4- / Pilot On

6- Coolant Flow (freq)

7- Coolant Temp (analog)

9- / Temp OK (Inverter/Chopper)

10- / Coolant Level OK

12- Missing Phase

13- / Ready to Operate

15- / Input Volts OK

16- / Inverter OCR

18- / PS ID "00*"

19- / PS ID "0*0"

20- / PS ID "*00"

21- E-Stop

22- E-Stop

29,31,33- 24 VAC Supply

30,32,34- 24 VAC Return

Rx-

Tx+

Rx+

Tx-

OK to MOVE +

+15VDC

+5VDC

-15VDC

COOLANT FLOW (freq) *

I/O PCB

CPU PCB

ECO-B1535

9-25-09

88

22

+V

GN

D

SI

G

FL1

FLOW_TURBINE_PULSE

+V

GN

D

SI

G

FL1

FLOW_TURBINE_PULSE

R

B

G

55

RY3

RY3

12

12

J6

J6

1

5

8

TP17

TP17

CN9

CN9

1

2

3

4

5

J4

J4

1

3

5

7

CN2

CN2

1

2

K6

K6

D8

OK_CNC

D8

OK_CNC

J5

J5

1

2

3

4

5

CN24

CN24

1

2

3

4

5

6

YELLOW

TEMP

YELLOW

TEMP

RED

STATUS

RED

STATUS

33

LED1

LEVEL

LED1

LEVEL

PUMP

MOT1

PUMP

MOT1

'

.

CN14

CN14

1

2

77

C.P7

C.P7

TP18

TP18

CN6

CN6

1

2

3

4

CN5

CN5

1

2

3

4

5

6

MC2

MC2

33

11

R8

1K 30W

R8

1K 30W

TB2

TB2

+

RY10

+

RY10

1

2

TP11

TP11

CN9

CN9

1

2

3

D23

CNC_START

D23

CNC_START

44

66

TP1

TP1

TP10

TP10

GAS ON

GAS ON

J15-CNC

J15-CNC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

100K

100K

22

1

2

C.P6

C.P6

C.P2

C.P2

CN3

CN3

1

2

3

22

1

2

3

11

55

RY4

RY4

CN23

CN23

1

2

3

4

5

6

88

1

2

D7

E-STOP_PS

D7

E-STOP_PS

TB4

TB4

TP14

TP14

TP6

TP6

TP3

TP3

J59-RAS

J59-RAS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

GREEN1

GAS

GREEN1

GAS

TP9

TP9

TP5

TP5

J6 **

J6 **

1

2

3

4

5

6

J54-REMOTE HMI

J54-REMOTE HMI

1

2

3

4

5

6

7

8

9

10

11

12

13

14

66

RY9

RY9

12

12

RY5

RY5

TP2

TP2

66

TP12

TP12

OK2 *

OK2 *

11

11

99

1K

1K

D26

HOLD_START

D26

HOLD_START

D11

INITIALIZING / PROGRAMMING

D11

INITIALIZING / PROGRAMMING

TP16

TP16

CN10

CN10

1

2

3

CN8

CN8

1

2

3

4

CN1

CN1

1

2

t

TH1

t

TH1

10

10

77

J1

J1

1

2

3

4

5

6

7

8

9

CN11

CN11

1

2

MC1

MC1

1

2

3

PSR

PSR

D12

STATUS CODE

D12

STATUS CODE

TP4

TP4

44

55

11

11

88

GREEN

AC

GREEN

AC

33

D28

CNC_PREFLOW

D28

CNC_PREFLOW

CN13

CN13

1

2

3

10

10

+

RY1

+

RY1

C.P5

C.P5

TB1

TB1

T1

T1

460

220

0,

13

0,,

100

0.

200

0..

110

0...

120.

0_

24.

0__

24_

0___

120.

0___

D13

+5V

D13

+5V

TB3

TB3

CN7

CN7

1

2

3

4

J8

J8

1

2

3

4

1

2

3

11

12

12

99

44

K7-1

K7-1

GREEN2

DC

GREEN2

DC

TP7

TP7

RY11

RY11

TP8

TP8

77

C.P8

C.P8

E-STOP

E-STOP

J7

J7

1

2

3

4

5

6

7

8

9

FAN1

FAN1

+

-

TB5

TB5

TP15

TP15

D15

PSR

D15

PSR

CN8

CN8

1

2

3

4

CN12

CN12

1

2

C.P3

C.P3

D9

GAS_ON

D9

GAS_ON

10

10

J9

J9

1

2

3

4

5

6

D21

CNC_E-STOP

D21

CNC_E-STOP

LSW1-1

SW_LIQUID_LEVEL_NC

LSW1-1

SW_LIQUID_LEVEL_NC

CN4

CN4

1

2

3

22

CN12

CN12

1

2

3

J55-GCM

J55-GCM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

11

11

11

MC1 AUX

MC1 AUX

99

TP13

TP13

RY7

RY7

1

2

100K6

100K6

1

2

3

C.P4

C.P4

CN2

CN2

1

2

3

4

5