tekmar 422 Universal Reset Module User Manual

Page 23

23 of 32

© 2007

D 422 - 08/07

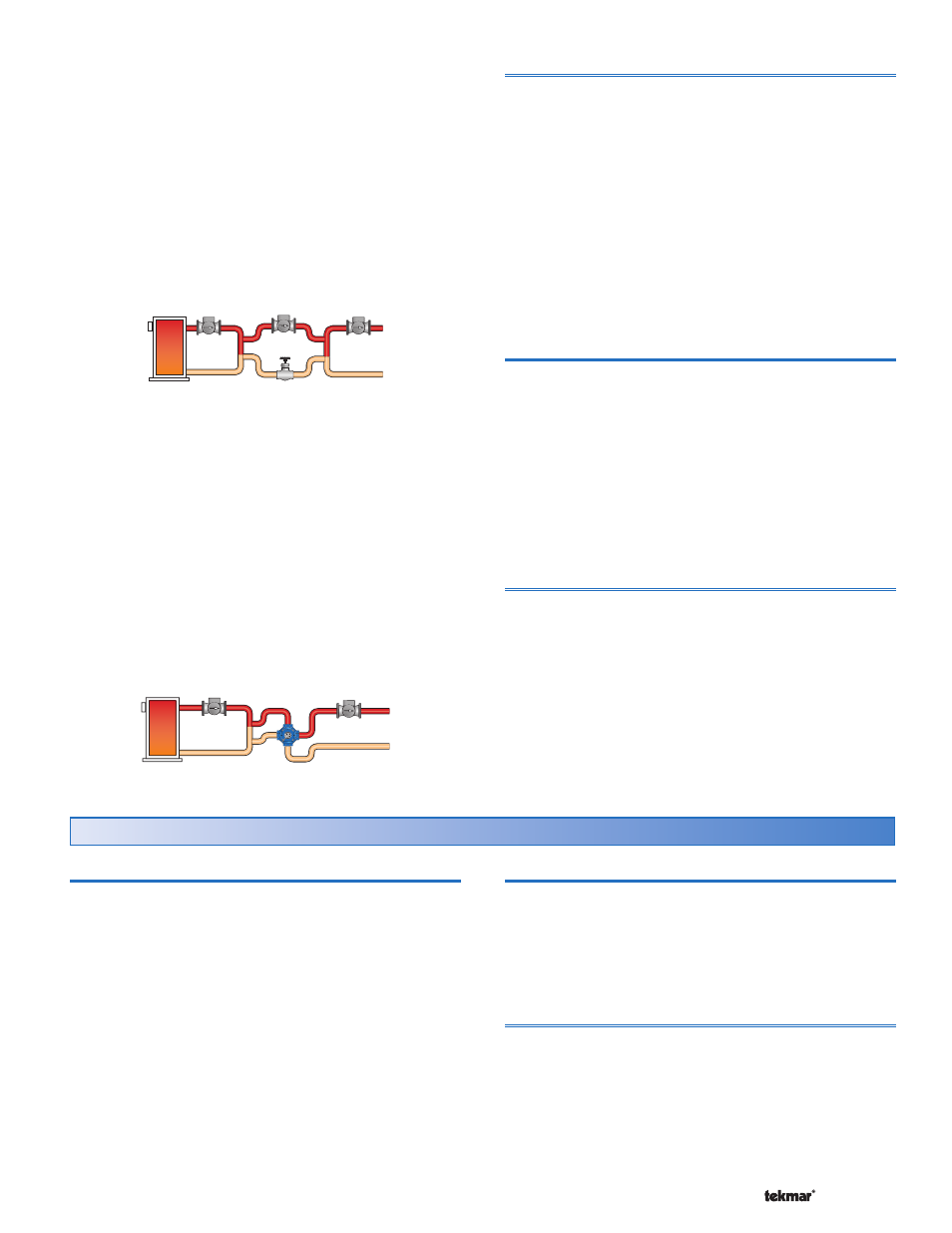

Variable Speed Injection

A standard wet rotor circulator can be connected to the

Variable Speed output on the control for Mix 1 and on

a Mixing Module for Mix 2. The control increases or

decreases the power output to the circulator when there

is a requirement for mixing. The circulator speed varies to

maintain the correct mixed supply water temperature at

the mix supply sensor. For correct sizing and piping of the

variable speed injection circulator, refer to essay E 021.

A visual indication of the current variable speed output is

displayed in the LCD in the form of a bar graph along with

the Mix 1 or the Mix 2 segment to indicate which mixing

device is being currently viewed.

Floating Action

A floating action actuator motor can be connected to the

control (Mix 1) or a Mixing Module (Mix 2) on the Opn and

Cls terminals. The control pulses the actuator motor open

or close to maintain the correct supply water temperature

at the mix supply sensor when there is a requirement for

mixing. The mixing valve that the actuator is connected

to can be either a 2-way, 3-way or 4-way valve. A visual

indication as to whether the control is currently opening or

closing the mixing valve is displayed in the LCD with the

words OPN and CLS while viewing the Mix Supply or Mix

Target temperatures. Also, a visual indication of the current

position of the valve is displayed in the form of a bar graph

along with the Mix 1 or the Mix 2 segment to indicate which

mixing device is being currently viewed.

Mix 1 and Mix 2 Minimum

The Mix 1 and Mix 2 Minimum settings are the lowest

temperature that the control is allowed to use as a mix

target temperature. During mild conditions, if the control

calculates a mix target temperature that is below the mix

minimum setting, the mix target temperature is adjusted

to match the mix minimum setting. During this condition,

if the mixing supply temperature is near the mix minimum

setting, the Min segment turns on in the LCD when either

the mix target temperature or the mix supply temperature

is being viewed.

•

• Locate the Mix 1 and the Mix 2 Minimum settings in the

Adjust menu.

Mix 1 and Mix 2 Maximum

The Mix 1 Maximum and Mix 2 Maximum set the highest

water temperature that the control is allowed to use as a

mix target temperature. If the control does target the mix

maximum setting, and the mix supply temperature is near

the mix maximum temperature, the Max segment turns on

in the LCD when either the mix target temperature or the

mix supply temperature is viewed.

•

• Locate the Mix 1 and the Mix 2 Maximum settings in the

Adjust menu.

Boiler Minimum Protection

The control is capable of providing boiler protection from

cold mixing system return water temperatures. If the boiler

water temperature is cooler than the Boiler Minimum setting

while the boiler is firing, the control reduces the output from

the mixing devices. Both mixing outputs are reduced at the

same rate. Reducing the mixing output limits the amount of

cool return water to the boiler and allows the boiler water

temperature to recover. This feature can only be used if

the boiler sensor is on the supply or on the return but is not

available when the boiler sensor is not present.

Domestic Hot Water Temperature Operation

Section H

DHW Demand

A powered DHW Demand is required in order for the control

to provide heat to the DHW system. A DHW aquastat or

setpoint control is used as a switch in the DHW demand

circuit. The control registers a DHW Demand when a

voltage between 24 and 230 V (ac) is applied across the

DHW Demand terminals (53 and 54).

Once the control detects a DHW demand, the DHW Demand

segment turns on in the LCD.

Boiler Target Temperature

The boiler target temperature is at least as hot as the DHW

Exchange setting. The DHW demand overrides the boiler

reset target temperature, except when the boiler reset target

is higher than the DHW exchange setting.

•

• Locate the DHW Exchange setting in the Adjust menu.

DHW During UnOccupied

The control has a DHW Exchange UnOccupied setting that

allows the installer to select On or Off. When set to On, and

the control receives a DHW Demand during an UnOccupied

or Sleep period, the control continues operation of the DHW

system as it would during the Occupied and Wake periods.

When set to Off, the control can ignore a DHW Demand for

the duration of the UnOccupied and Sleep periods.