Sequence of operation, Tekmarnet – tekmar 422 Universal Reset Module User Manual

Page 16

© 2007

D 422 - 08/07

16 of 32

tekmarNet

®

4 Communication

Section A

tekmarNet

®

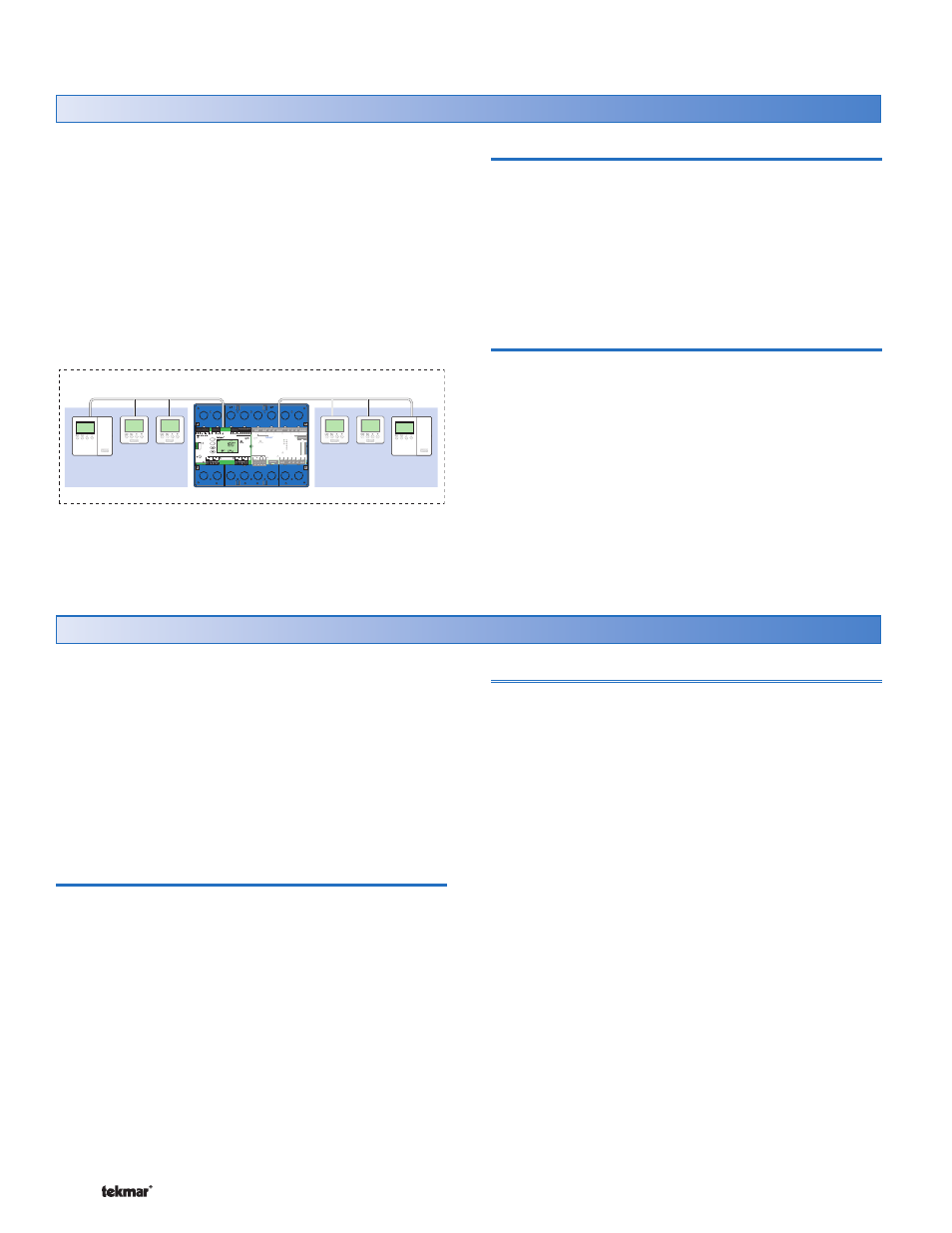

4 (tN4) communicates between tN4 devices

(thermostats, Reset Module and Expansion Modules).

Each tN4 device is connected to a tN4 communication

bus using two wires. Each tN4 bus adjusts a single water

temperature in the system using indoor temperature

feedback. The Universal Reset Module 422 allows for two

tN4 buses. This allows you to control a system with two

separate water temperatures.

A system that has more than one tN4 bus is referred to as

a tN4 network.

Outdoor Reset Module

The Universal Reset Module 422 is the system control

for a hydronic heating system. The 422 operates a single

heat source such as a boiler, one or two mixing devices,

a domestic hot water tank, and responds to other heating

requirements such as pool heating and snow melting. The

422 also coordinates and optimizes the operation of all the

tN4 thermostats.

tN4 Thermostat

The tN4 thermostat operates heating, cooling, and or

ventilation equipment for a zone. Several tN4 thermostats

may work in a group when operating a cooling system. Up

to 24 tN4 thermostats can connect to a single tN4 bus.

Outdoor Reset

Section B

In a heating system, the rate of heat supplied to the building

must equal the rate of which heat is lost. If the two rates are

not equal, the building will either cool off or over heat.

The rate of building heat loss depends mostly on the outdoor

temperature. Outdoor Reset allows a hot water heating

system to increase the water temperature, adding heat to

the building, as the outdoor temperature drops. The rate

at which the water temperature is changed is defined by

the characterized heating curve.

Characterized Heating Curves

A characterized heating curve determines the amount the

supply water temperature is raised for every 1° drop in

outdoor air temperature. There is a characterized heating

curve for each tN4 communication bus.

The characterized heating curve takes into account the

type of terminal unit that the system is using. Since different

types of heating terminal units transfer heat to a space using

different proportions of radiation, convection and conduction,

the supply water temperature must be controlled differently.

Each tN4 bus is assigned a terminal unit setting that the

control uses to vary the supply water temperature to suit

to the terminal unit used. This improves the control of the

air temperature in the building.

Indoor Temperature Feedback

Most buildings have internal heat gains due to people,

passive solar heating and mechanical or electrical equipment.

Likewise, wind loads cause a building to lose heat faster than

during design conditions. If only the outdoor temperature is

measured, the control cannot compensate for these internal

heat gains or loses and the building may over or under heat.

In order to maintain the most comfortable temperature,

the control uses indoor temperature feedback from tN4

thermostats in order to adjust the water temperature on

each tN4 bus on a continual basis.

Sequence of Operation

Zone A1

Zone A2

Power

Zone Group Pump A

Zone A3

Zone B1

Zone B2

Zone B3

tN4

Zone Group Pump B

Bus 1

Bus 2

Network

tekmarNet

®

4

Thermostats

tekmarNet

®

4

Thermostats

tN4

H7008B

Test

Item

Menu

/

Do not apply power