tekmar 263 Boiler Control User Manual

Page 6

©

2009 D

263

-

03/09

6

of

36

Section B: Boiler Operation

Section B1

Boiler

Operation

Section B2

Mode 1

Two Stage

Operation

Section B3

Mode 2

Modulating

Boiler Operation

Section B1: Boiler Operation

BOILER TARGET TEMPERATURE

The boiler target temperature is determined by the type of demand received by the control. A boiler demand calculates a boiler

target based on the characterized heating curve settings and the outdoor air temperature. A DHW demand and a Setpoint demand

have temperature settings to which the boilers are operated to meet.

The control displays the temperature that it is currently trying to maintain as the boiler supply temperature. If the control does not

presently have a requirement for heat, it does not show a boiler target temperature. Instead, “– – –” is displayed in the LCD.

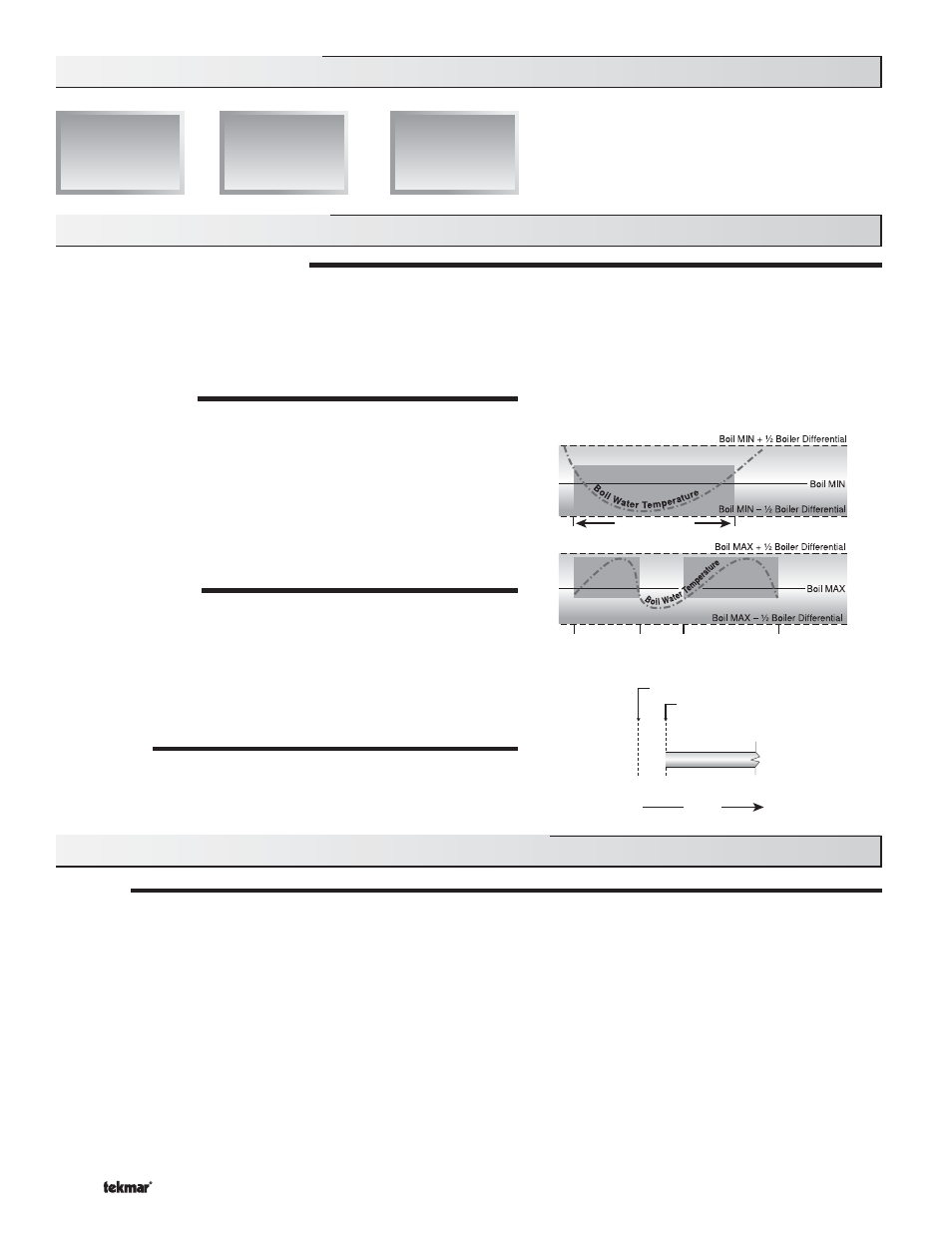

BOILER MINIMUM

The boiler minimum is the lowest temperature that the control is

allowed to use as a boiler target temperature. During mild conditions,

if the control calculates a boiler target temperature that is below the

Boiler Minimum

setting, the boiler target temperature is adjusted to at

least the Boiler Minimum setting. During this condition, if the boiler(s) is

operating, the minimum segment is turned on in the display when viewing

either the boiler supply temperature or the boiler target temperature. Set

the Boiler Minimum setting to the boiler manufacturer’s recommended

temperature.

BOILER MAXIMUM

The boiler maximum is the highest temperature that the control is

allowed to use as a boiler target temperature. If the control does target

the Boiler Maximum setting, and the boiler temperature is near the boiler

maximum temperature, the maximum segment will be displayed in the

LCD while either the boiler target temperature or the boiler temperature

is being viewed. At no time does the control operate the boiler(s) above

248°F (120°C).

FIRE DELAY

The Fire Delay is the time delay that occurs between the time that the control

closes a stage contact to fire a stage and the burner fires for that stage.

MIN Segment On

MAX Segment

On

MAX Segment

On

Boiler

Contact Closes

Boiler

Fires

Fire

Delay

Time

Section B2: Mode 1 - Two On / Off Stages Operation

STAGING

When operating in mode 1, the control operates up to two on / off stages in order to provide the required supply temperature. After

a stage is turned on in the firing sequence, the control waits for a minimum time delay. The minimum time delay is adjustable using

the Stage Delay setting. After the Stage Delay has expired, the control examines the control error to determine when the next stage

is to fire. The control error is determined using Proportional, Integral and Derivative (PID) logic.

Proportional

compares the actual supply temperature to the boiler target temperature. The colder the supply water temperature,

the sooner the next stage is turned on.

Integral

compares the actual supply temperature to the boiler target temperature over a period of time.

Derivative

compares how fast or slow the supply water temperature is changing. If the supply temperature is increasing

slowly, the next stage is turned on sooner. If the supply temperature is increasing quickly, the next stage is turned

on later, if at all.