Powers 450-410 HydroPanel II Shower System User Manual

Page 4

TI450-410

Page 4

ORDERING

TROUBLESHOOTING, CONTINUED

b. The mixing plate may be damaged. Replace with Repair Kit

#410-378*.

5. If the handle does not fit properly on the stem and the

water leaks from the valve shut off...

a. The handle splines on the stem and/or the mixing plate may

be damaged. Replace with Repair Kit #410-378*.

6. If the checkstops leak, or they won’t shut off...

a. The checkstops may be damaged. Clean and service with

Repair Kit #141-845*.

7. If a maximum temperature cannot be obtained...

a. Lime deposits may have accumulated in the hot water pipes,

restricting the hot water supply.

b. The hot water supply temperature may be too low.

c. The handle rotation setting may be too low. Remove valve

handle, and readjust the handle rotation stop (see Setting the

Handle Rotation Stop).

d. The diaphragm assembly may have failed. Replace with

Repair Kit #410-183*.

8. If the valve opens with hot water flow rather than cold

water flow...

a. The supply water inlets may be reversed, or the mixing plate

orientation may be incorrect. Refer to Figure 6.

1. Turn the valve handle to full clockwise position (OFF).

2. Turn off supply water and access the valve.

3. Check that the adjustment stem faces the correct direction for

valve operation:

•

For NORMAL operation, Hot Inlet is on the left and Cold Inlet

is on the right, and with the valve in shut off position, the notch

in the splined stem faces the UP (toward the water outlet).

•

For REVERSE valve operation, Cold Inlet is on the right and

Hot Inlet is on the left, and with the valve in shut off position,

the notch in the splined stem faces DOWN.

4. To change the stem ori-

entation, pull up but do

not remove the stem O-

ring and handle rotation

stop.

5. Turn the stem 180° so

the notch faces the

appropriate direction

(see above).

6. Replace handle rotation

stop and O-ring. Test

the system. Replace

shroud, cover plate and valve handle.

For normal operation, the

notch in handle stem must

face water OUTLET (top).

HOT

COLD

HOT INLET

OUTLET

COLD INLET

Figure 6.

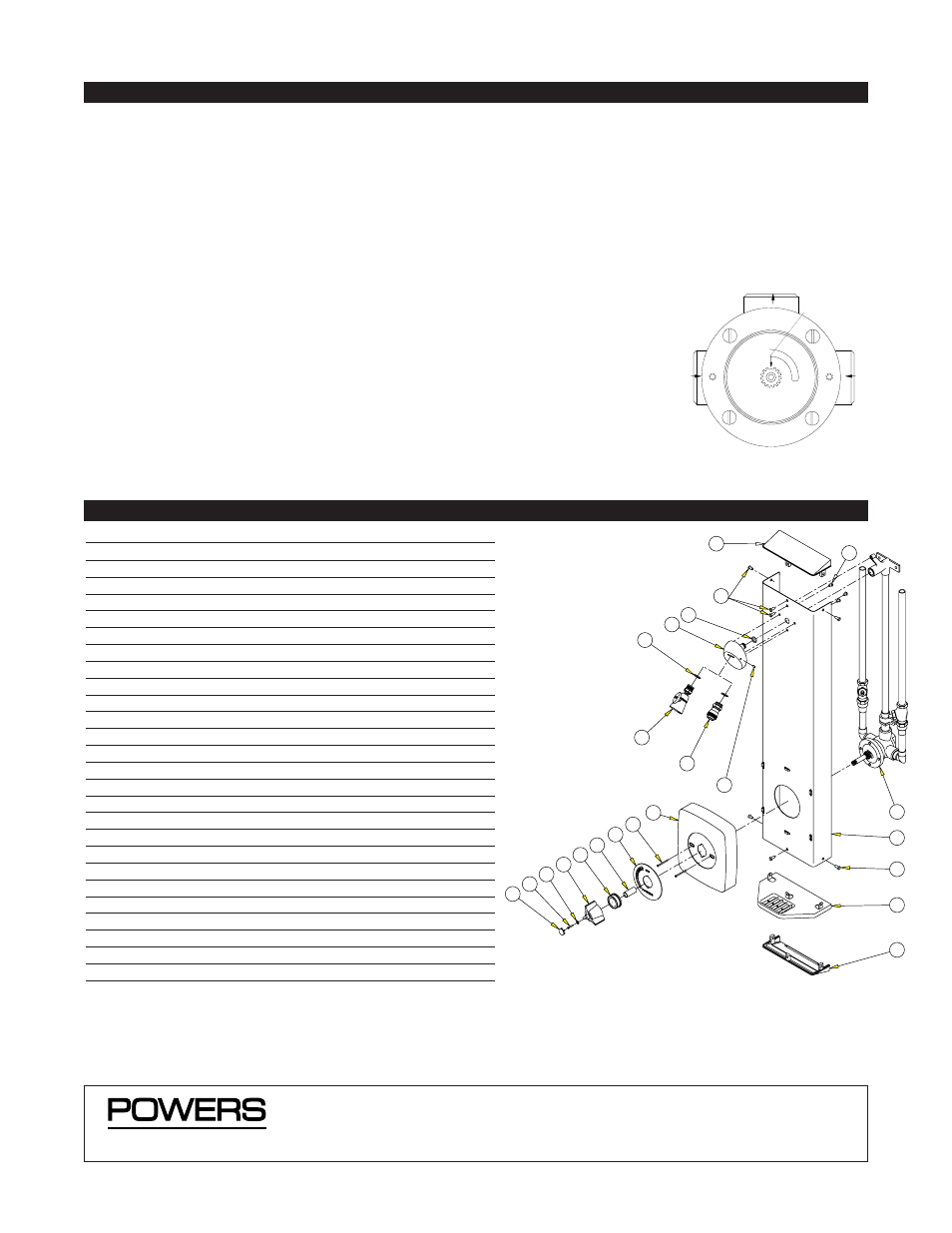

2

4

6

7

8

9

10

11

12

14

15

19

20

21

18

26

27

28

33

6

5

5

13

#

Part #

Description

Qty

Material

2

NA

Shroud 410/420

1

St Steel

4

450 268

Soap Dish

1

St Steel

5

4504011

End Cap Kit

1

Chrm Plt ABS

6

450 273

Screw 10-32 x 3/8 (shrouding)

7

St Steel

NS

141 837

Handshower with 18” Glidebar

1

-

7

450 276

Set Screw 10-32 x 7/8

1

St Steel

8

141 816

Fixed Showerhead

1

Chrm Plt Brass

9

141 815

Adjustable Swivel Showerhead

1

Chrm Plt Brass

10

450 277

Gasket, Showerhead Base

1

Garlock 3000

11

450267G

Showerhead Base

1

Chrm Plt Brass

12

047 013

Quad Ring 3/8 x 1/2 x 1/16

1

Buna N

13

450 274

Screw 10-32 x 1/4 (showerhead)

3

Brass

14

410 195

Button Plug (tri-handle)

1

Ni Plt Brass

15

450 271

Screw 8-32 x 1/2 (tri-handle)

1

St Steel

NS

034224G

Screw (lever handle)

1

St Steel

18

046008K

Shakeproof Washer (tri-handle)

1

Cad Plt Brass

19

410 191

Tri-Handle

1

Chrm Plt Znc

NS

420 301

Lever Handle

1

Chrm Plt Znc

20

410 367

Retainer (dial) Kit (1 needed)

10

Buna -S

21

401 267

Sleeve for 410

1

Chrm Plt Cu

26

410 442

Graphics Insert

1

Al w/Mylar

27

080 013

Screw 8-32 x 1-1/2 (dial insert)

2

St Steel

28

NA

Cover Plate

1

St Steel

33

NA

Hydroguard/Piping Assembly

1

-

NS

089 003

3/32” Service Wrench

1

Steel

NS

089 004

1/8” Service Wrench

1

Steel

NS = Not shown in diagram

NA = Not available as commercial part

Figure 7. Exploded View Diagram of

Hydropanel II Series 450-0410 or

450-0412 Shower Unit.

© Reprinted March 2002 Powers, a Watts Industries Co.

3400 Oakton Street, Skokie, IL 60076 Phone: 800.669.5430 • 847.673.6700 • Fax: 847.673.9044

www.powerscontrols.com

5435 North Service Road, Burlington, Ontario, L7L 5H7 Canada • Phone: 888.208.8927 • Fax: 888.882.1979

A Watts Industries Co.

Form

TI

450-410 0218

EDP# 6508970

Printed in U.S.A.