Powers 430/1430 Series HydroGuard Multi-Valve Hi/Lo Systems User Manual

Page 2

PRIOR TO INSTALLATION

1.

Flush all piping thoroughly.

2.

Make sure all valve handles are rotated fully clockwise

(off).

3.

If you use copper tubing, excessive heat from soldering

will damage the internal parts of the valve. Take care to

protect valve components or remove the internal parts

of the valve and checkstops before soldering.

4.

IMPORTANT

In order to make any temperature adjustments to the

valves, you must open enough showerheads (or end-

of-line fixtures) to ensure you have adequate flow

across the valve. For example, the 431 requires a min-

imum flow of 7 GPM to operate properly. The 420

requires a minimum flow of 2 GPM. Refer to the flow

chart for additional information.

5.

Use a thermometer at the showerhead or install an in-

line thermometer at the point of use..

SET UP PROCEDURE

You MUST FOLLOW THESE PROCEDURES in order to

properly adjust your Hi/Lo System.

You need proper flow across the valves in order to set a

maximum temperature.

Refer to the Individual Setting Procedures as guided in

these directions.

1.

Close the 420 Valve by turning the handle fully clock-

wise.

2.

Open the ball valve at the discharge of the 430 series

valve.

3.

Open one fixture.

4.

Set the PRV for a 15 psi differential. (See Setting the

PRV)

5.

Close the Ball valve at the discharge of the larger valve

and open the smaller valve by rotating the handle fully

counterclockwise.

6.

Open enough fixtures for a flow of at least:

2 GPM if the small valve is a 420

4 GPM if the small valve is a 427

7.5 GPM if the small valve is a 431

7.

Set the maximum temperature for the smaller valve

(Refer to Individual Setting Procedures for the 420,

427 or 430).

8.

When the valve has the correct maximum temperature

setting, close the smaller valve.

9.

Open the ball valve at the discharge of the larger valve.

10. Open additional fixtures so that enough water flows

through the larger valve:

7.5 GPM if the large valve is a 431

15 GPM if the large valve is a 432

24 GPM if the large valve is a 433

40 GPM if the large valve is a 434

11. Set the maximum temperature for the larger valve

(Refer to Individual Setting Procedures for the 430).

12. When water is at desired outlet temperature, shut off all

end of line fixtures (showerheads).

13. Open the smaller valve.

14. Test the Control: Verify temperature control over a wide

range of flow by opening a fixture and monitoring the

discharge temperature. Gradually open additional fix-

tures to verify that flow through both valves is properly

controlled.

15. For any problems, refer to Troubleshooting.

INDIVIDUAL SETTING PROCEDURES

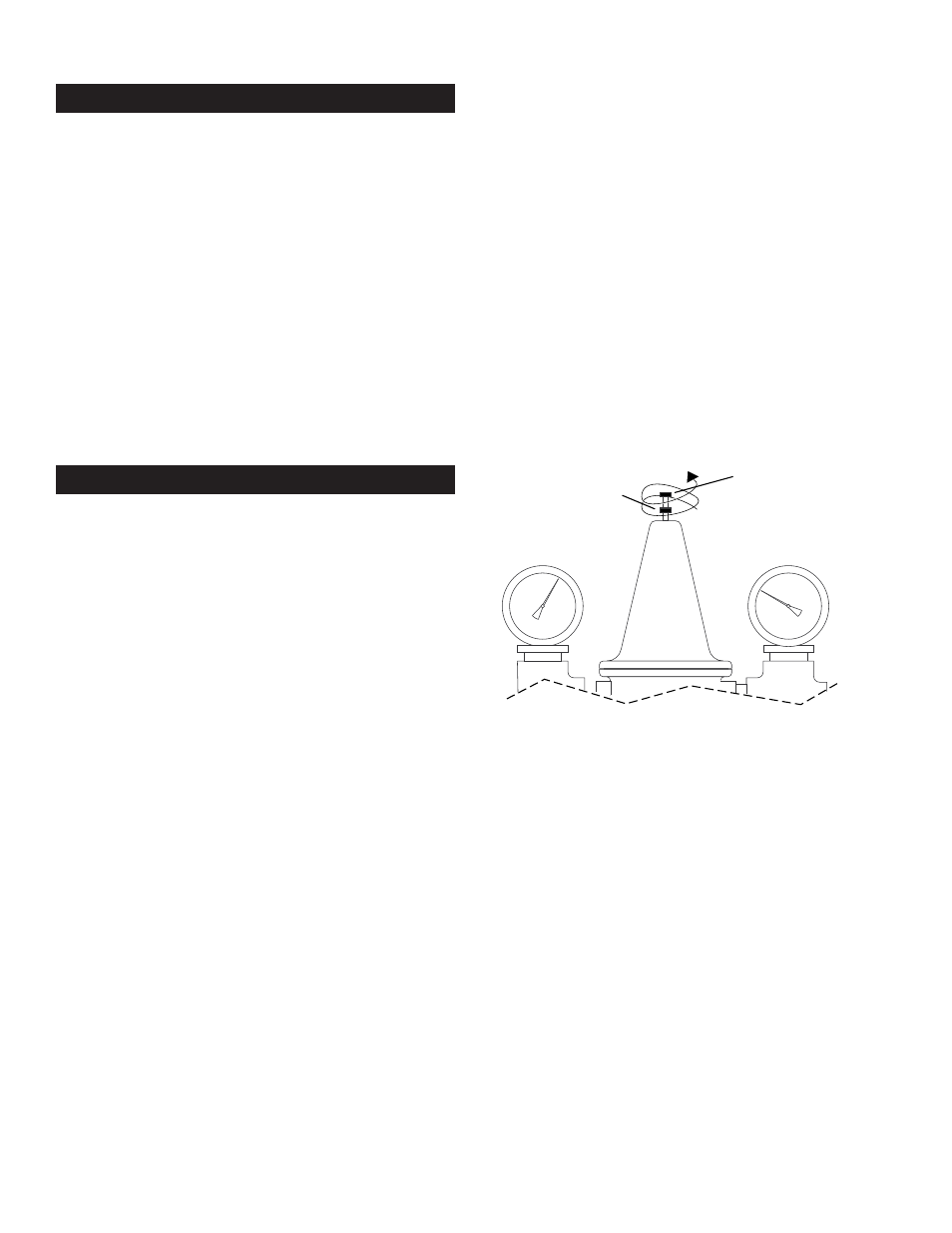

Set the PRV Valve

The Hi/Lo Assembly has one pressure gauge on each side of

the Pressure Reducing Valve. The left measures the supply

pressure, the right measures the output pressure going to

the fixtures. The PRV should be set so that the outlet pres-

sure gauge is approximately 15 psi less than the supply

pressure gauge (a 15 psi differentail across the PRV).

1.

Loosen the lock nut at the top of the PRV Valve. This

must be all the way out or you will be limiting the range

of your adjustments.

2.

Adjust the PRV valve so the outlet pressure gauge (right)

reads approximately 15 psi less than the supply pres-

sure gauge (left).

Turning the adjustment nut clockwise will decrease the

differential across the PRV (allowing the PRV to open

sooner).

Turning the adjustment nut counterclockwise will

increase the differential across the PRV (allowing the

PRV to open later).

Adjust the temperature of the 420 valve

The Standard 420 Hydroguard valve was factory set to deliv-

er 115°F [46°C] tempered water.

1.

Turn the handle fully counterclockwise to deliver water

at the maximum temperature.

2.

Loosen and remove handle retaining screw and handle.

3.

If the measured temperature exceeds the desired maxi-

mum outlet temperature, move the limit stop one spline

Supply Pressure Gauge

Outlet Pressure Gauge

2.

Adjustment Nut

CW: decrease differential

CCW: increase differential

1.

Lock Nut

Turn fully CCW

before setting PRV

TI430-420

Page 2