Powers 430/1430 Series HydroGuard Multi-Valve Hi/Lo Systems User Manual

Description, Operation, Application

DESCRIPTION

The Powers 430 Hi/Lo Supply Fixture is a pre-piped system

consisting of two thermostatic valves and a PRV, designed

to provide consistent temperature control over a wide range

of flow requirements.

The unit includes: A Powers Series 430 thermostatic mixing

valve, a Powers Series 420 or 427 thermostatic mixing valve,

a Pressure Reducing Valve (PRV), pressure gauges, union

inlet strainer checkstops, dial thermometer, shut-off ball

valve, and interconnecting piping.

All components are pre-assembled for easy installation. The

stainless steel or durable white baked enamel steel cabinets

are designed for recessed or wall mount installation and pro-

vide protected access to the system.

OPERATION

This two valve supply fixture has a low capacity valve

that works in parallel with a high capacity valve.

During low demand, the low capacity valve will han-

dle the load requirements. As the load demand is

increased, the pressure reducing valve, which is set

at a certain pressure differential, will open and allow

flow through the high capacity valve to assist the low

capacity valve in meeting the load requirements.

APPLICATION

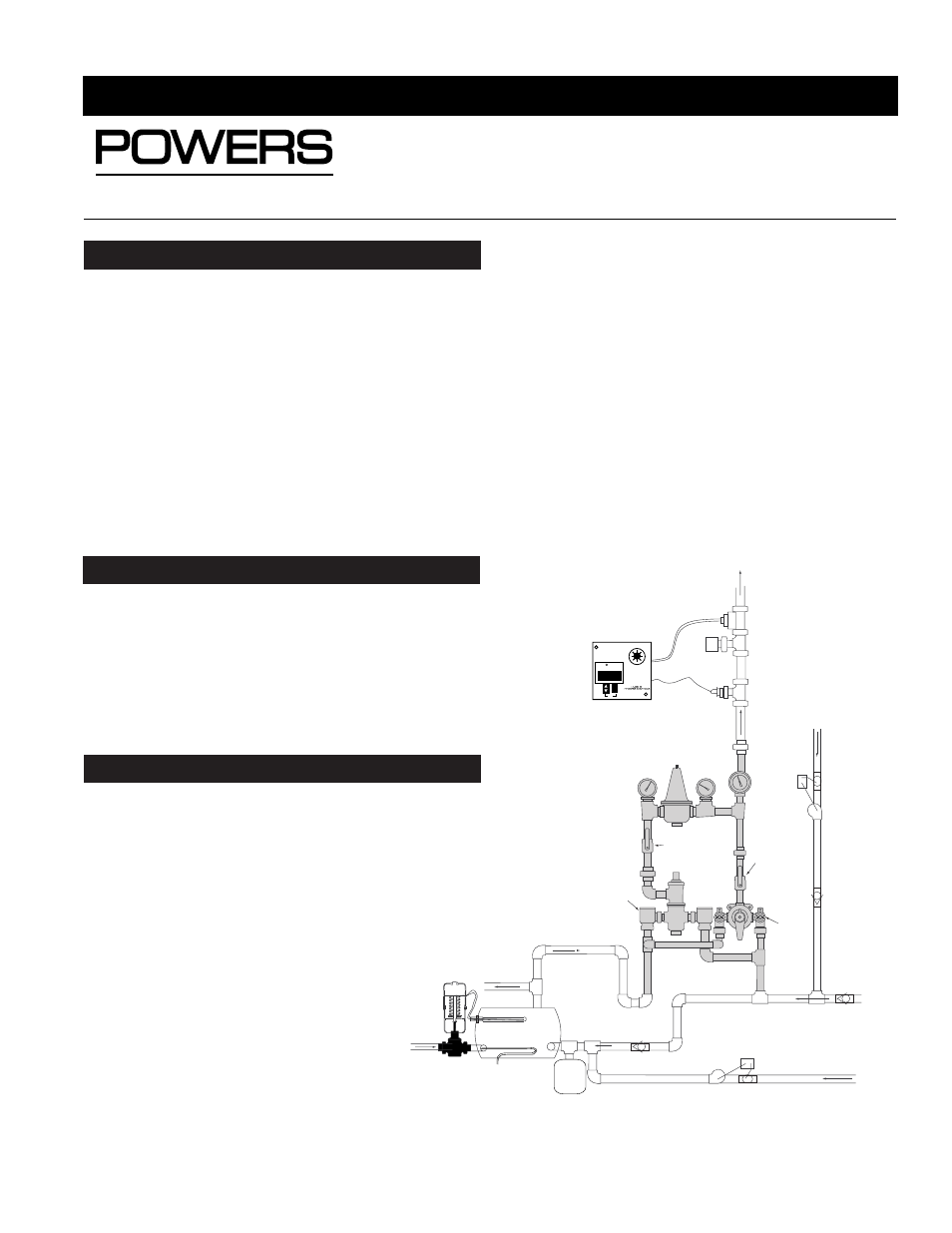

This is a typical application of the Hi/Lo Supply

Fixture for recirculation. Basic guidelines for

recirculating are provided below. Following

these guidelines will ensure stable

control of the domestic water

system during normal and

low/no use periods. Improper

piping causes the recirculat-

ing system to have erratic

pressure and temperature

fluctuations.

For Capacity requirements,

Refer to Form #MV430-3.5 or

the Hi/Lo Supply Fixture Brochure.

•

DO NOT recirculate low temperature hot water (LTHW)

and high temperature hot water (HTHW) with one pump;

return water may come back hotter than mixer set point.

•

To minimize natural heat convection, locate master

mixer below hot water source, or install mixer with heat

trap (a two-foot drop in the pipe line) as shown.

•

Do use two (2) circulating pumps. Use check valves to

prevent reverse flow.

•

Always use an Aquastat set at a temperature below set

point of mixer.

•

Be certain HTHW cannot be introduced into cold side of

mixer.

•

Always tie LTHW return to cold water side of mixing

valve, as well as back to hot water source.

WARNING

DO NOT OMIT THE LTHW CONNECTIONS; scalding and

severe personal injury may result from return supply

temperatures approaching hot water heater tempera-

tures.

A Watts Industries Co.

WATER

HEATER

STEAM

INPUT

PRV

HTHW

HTHW RETURN

CW

HEAT TRAP

LTHW

RETURN

LTHW

AQUASTAT

PUMP

Hi

AQUASTAT

PUMP

S u p p l y P r e s s u r e

G a u g e

O u t l e t P r e s s u r e

G a u g e

B a l l V a l v e

B a l l V a l v e

C h e c k s t o p s

C h e c k s t o p s

Lo

EXPANSION

TANK

S e n s o r

S h o c k A b s o r b e r

S o l e n o i d V a l v e

( O p t i o n a l )

2

qua

entry

AS

uality…Our Commitment

Q

qua

entry

AS

SERIES 460 ALARM

°

F

.

TEST

Set

Reset

TECHNICAL INSTRUCTIONS

HI/LO SUPPLY FIXTURE SYSTEM

Operation, Testing, Maintenance

TI430-420