Powers SH1430 2 Valve HiLo & DV User Manual

Technical instructions

HydroGuard

®

XP Series LFSH1430

2 Valve Hi/Lo

Technical Instructions

IS-P-SF-SH1430-2V-HiLo

Advanced Thermal Activation

Description

n

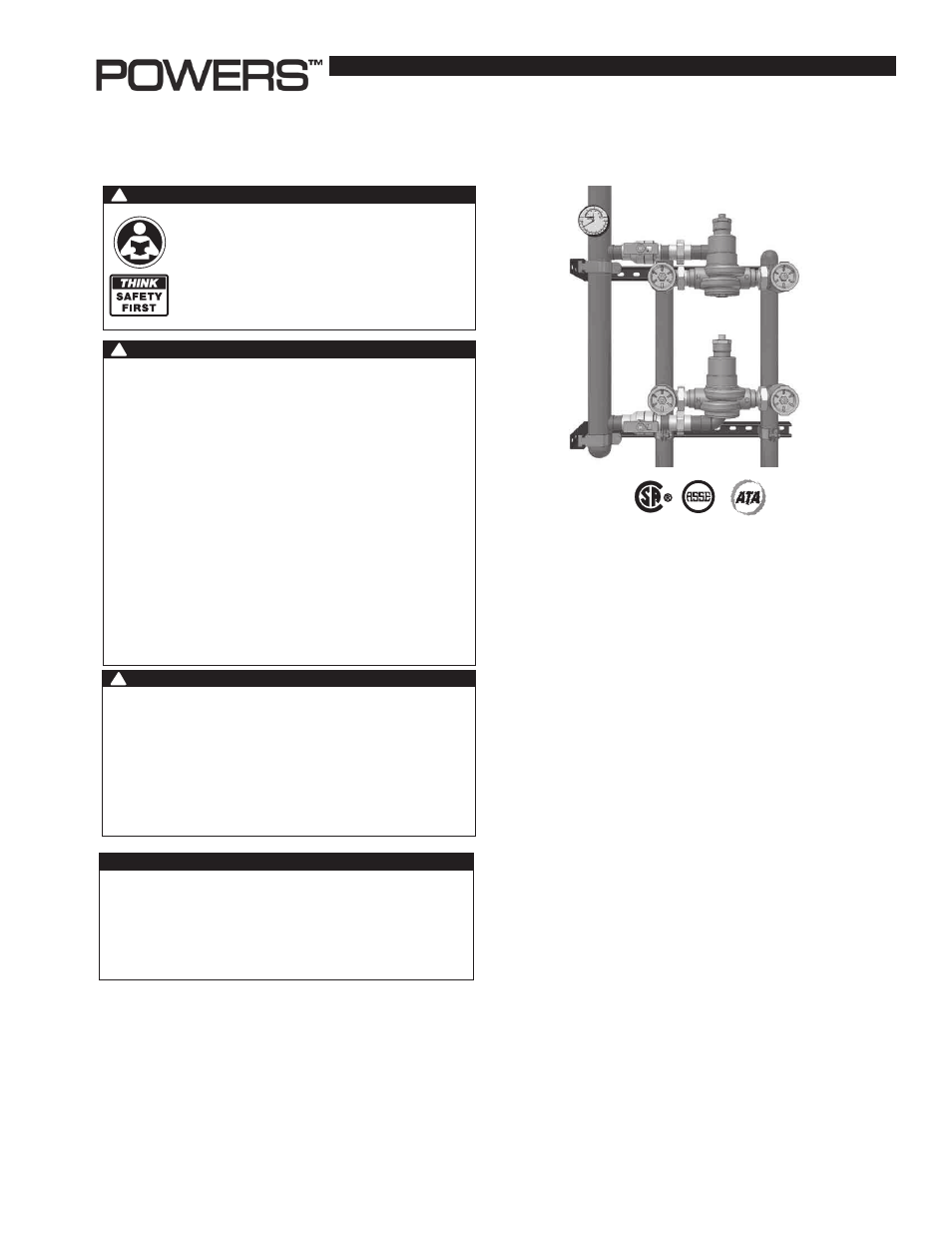

Powers' HydroGuard

®

XP Series LFSH1430 Hi/Lo systems are

fully assembled factory tested systems, designed to provide

safe water throughout commercial and institutional facilities.

HydroGuard

®

XP Series LFSH1430 Hi/Lo systems consist of

LFMM430 and Series LFSH1430 thermostatic valves which

utilize paraffin-based actuation technology to sense and adjust

outlet temperature.

Each system includes ball valves, pressure/temperature

gauges and Powers' triple-duty checkstops. Hi/Lo systems also

include a PRV. Optional equipment include cabinets.

Operation

n

Two-valve supply fixtures feature a low capacity valve that

works in parallel with a high capacity valve. During low

demand, the low capacity valve handles the load requirements.

As the load demand is increased, the pressure reducing valve,

which is set at a certain pressure differential, will open and

allow flow through the high capacity valve to assist the low

capacity valve in meeting the increased load requirements.

WARNING

!

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use infor-

mation can result in death, serious personal injury,

property damage, or damage to the equipment.

Keep this Manual for future reference.

You are required to consult the local building and plumb-

ing codes prior to installation. If the information in this

manual is not consistent with local building or plumbing

codes, the local codes should be followed. Inquire with

governing authorities for additional local requirements.

WARNING

WARNING

!

Need for Periodic Inspection and Yearly Maintenance:

Periodic inspection and yearly maintenance by a licensed con-

tractor is required. Corrosive water conditions and/or unauthor-

ized adjustments or repair could render the valve ineffective for

service intended. Regular checking and cleaning of the valve’s

internal components and check stops helps assure maximum

life and proper product function. Frequency of cleaning and

inspection depends upon local water conditions.

FAILURE TO COMPLY WITH PROPER INSTALLATION AND

MAINTENANCE INSTRUCTIONS COULD CONTRIBUTE TO THE

VALVE FAILURE.

This Hot Water Master Tempering Valves cannot be used for

tempering water temperature at fixtures. Severe bodily injury

(i.e., scalding or chilling) and/or death may result depending

upon system water pressure changes and/or supply water

temperature changes. ASSE standard 1016, 1069 or 1070 listed

devices should be used at fixtures to prevent possible injury.

These Hot Water Tempering Valves are designed to be

installed at or near the boiler or water heater. They are not

designed to compensate for system pressure fluctuations and

should not be used where ASSE standard 1016, 1069 or 1070

devices are required. These valves should never be used to

provide “anti-scald” or “anti-chill” service.

The components of the system must be of materials with a

construction capable of withstanding the high limit output tem-

peratures of the water heating source.

WARNING

!