Powers MM430 Master Tempering Valves User Manual

Page 2

1. Installation should be in accordance with acceptable plumb-

ing practices. Flush all piping thoroughly before installation.

Installation and field adjustment are the responsibility of the

installer.

2. Valves are to be installed as close to building inlet supply as pos-

sible to prevent/minimize pressure fluctuations.

3. Valve body can be rotated to install in multiple position due to

union inlets (see Figure 2). Make sure that union nuts are tight-

ened securely.

4. Connect inlets and outlet and check for leaks.

5. When the Hydroguard supplies tempered water to self-closing

and/or solenoid valves, provide a shock absorber (Powers Part

No. 460-353) on the discharge line.

6. Before use, check discharge temperature. Reset if nec-

essary.

Operation Check:

After Hydroguard is installed, make certain the supply stop valves

and strainers are free and clean and ready for operation by disas-

sembling checkstops as shown in servicing.

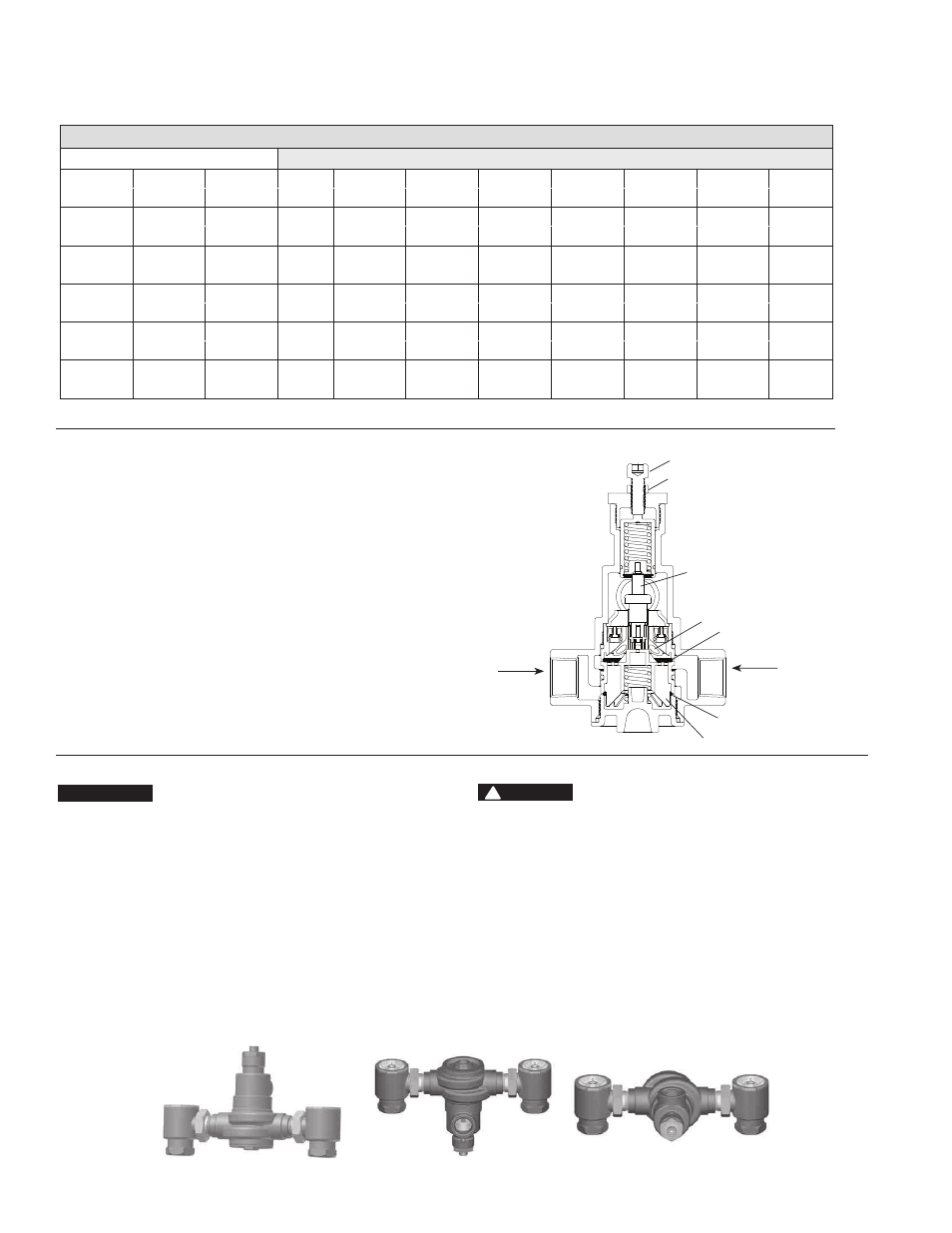

Typical Flow

Hot and cold water supplies enter Hydroguard at indicated ports,

(see Figure 1) then flow past their respective balanced poppet plug

and seats. Next, hot and cold water flow is directed to the mixing

chamber where the thermostatic actuator is located.

Temperature adjustment screw moves the actuator to determine the

discharge temperature.

With a rise in discharge temperature due to pressure or tempera-

ture fluctuation on the inlet, the actuator expands, decreasing flow

of hot water. The reverse occurs with a drop in discharge

temperature.

• Cold water supply failure – causes actuator to expand allowing

the motor to drastically reduce hot water flow.

*

• Hot water supply pressure failure – causes actuator to contract

allowing return spring to close cold water port

*

.

*

When tested in accordance to conditions described in ASSE 1017.

Installation Instructions

n

Operation

n

Figure 2

Back Outlet

Front Outlet

Top Outlet

2

Figure 1

Temperature Adjustment Screw

Temperature Adjustment Locknut

Actuator

Mixing Chamber

Cold Water Seat

Hot Water

Seat

Cold Water

Hot Water

Plunger

Table 1, Capacity Tables, present the Hydroguard discharge capacity in gpm and l/m for various pressure differentials (the difference

between the lowest inlet pressure and the discharge pressure at the Hydroguard).

Capacity

n

* Minimum flow when Hydroguard is installed at or near hot water source with recirculated tempered water with continuously operating recirculating pump.

Flow Capacity at 50-50 mixed ratio

P r e s s u r e D r o p A c r o s s V a l v e

Model

Min.

Min. Flow

5psi

10psi

20psi

30psi

45psi

60psi

70psi

Flow Rate*

to ASSE 1017

C

V

(34 kPa)

(69 kPa)

(138 kPa)

(207 kPa)

(310 kPa)

(414 kPa) (517 kPa)

LFMM431

0.5 gpm

3 gpm

6.32

14 gpm

20 gpm

28 gpm

35 gpm

42 gpm

49 gpm

53 gpm

1.89 lpm

11 lpm

53 lpm

76 lpm

106 lpm

132 lpm

159 lpm

185 lpm

201 lpm

LFMM432

0.5 gpm

4 gpm

9.49

21 gpm

30 gpm

42 gpm

52 gpm

64 gpm

74 gpm

79 gpm

1.89 lpm

15 lpm

80 lpm

114 lpm

159 lpm

197 lpm

242 lpm

280 lpm

299 lpm

LFMM433

0.5 gpm

5 gpm

16.44

37 gpm

52 gpm

74 gpm

90 gpm

110 gpm

127 gpm 138 gpm

1.89 lpm

19 lpm

140 lpm

197 lpm

280 lpm

341 lpm

416 lpm

481 lpm

522 lpm

LFMM434

0.5 gpm

7 gpm

21.50

48 gpm

68 gpm

96 gpm

118 gpm

144 gpm

167 gpm

180 gpm

1.89 lpm

26 lpm

182 lpm

257 lpm

363 lpm

447 lpm

545 lpm

632 lpm

681 lpm

LFMM435

0.5 gpm

10 gpm

31.00

69 gpm

98 gpm

139 gpm

170 gpm

208 gpm

240 gpm

259 gpm

1.89 lpm

38 lpm

261 lpm

371 lpm

526 lpm

644 lpm

787 lpm

908 lpm

980 lpm

NOTICE

CAUTION

!