Warning, Repair kit, Troubleshooting – Powers LM495 Series Thermostatic Tempering Valves for Individual Lavatory Installations User Manual

Page 2: Warranty, Quick-connect installation, Notice

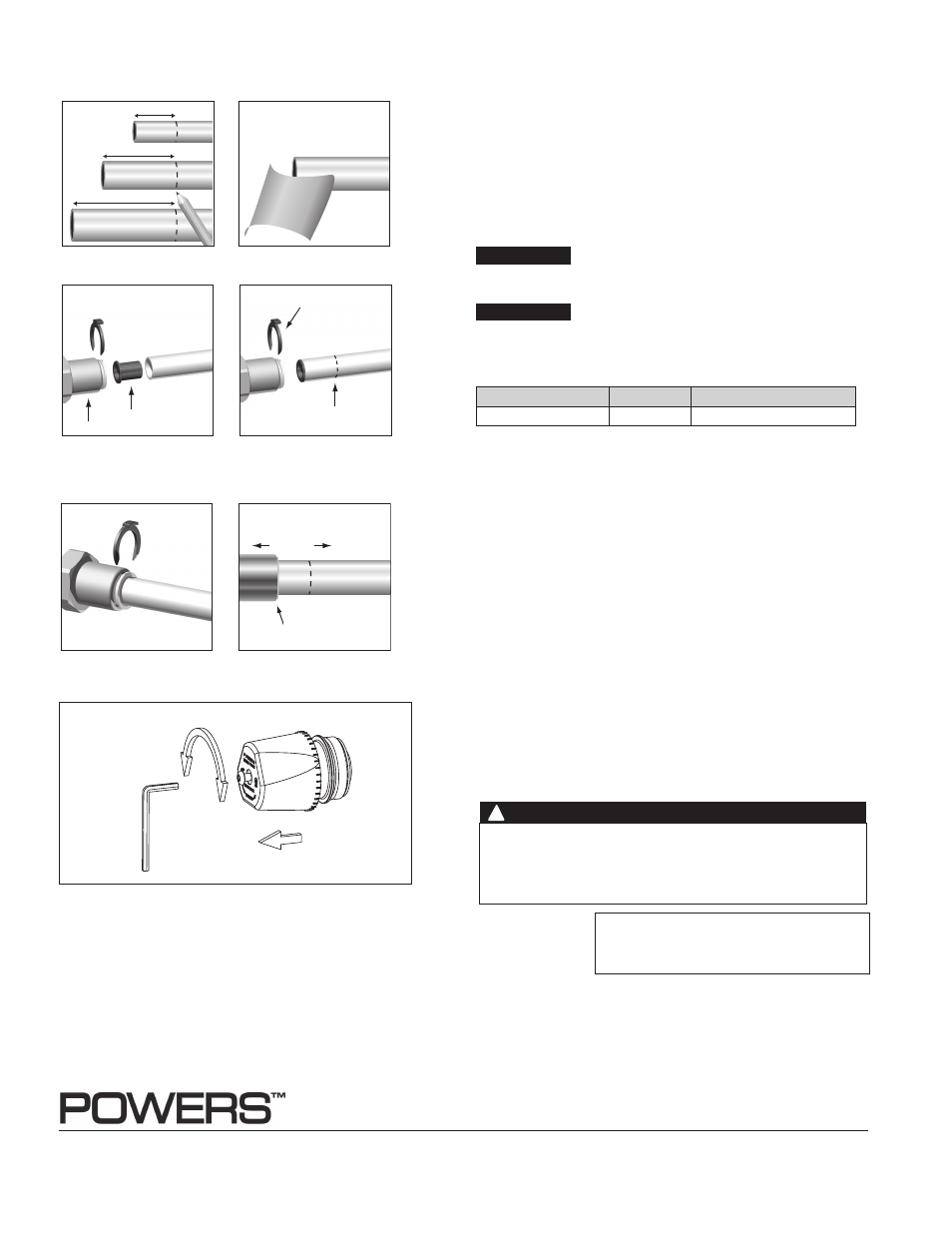

To Adjust Temperature (Figure 3)

n

1. Let the water flow for at least two minutes to allow supply tem-

perature to stabilize.

2. Place a thermometer in the outlet water stream.

3. Loosen handle screw with hex wrench.

4. Handle must be lifted

1

⁄

4

” to adjust temperature. Rotate handle

clockwise to decrease temperature and counter-clockwise to

increase the temperature.

5. Lower handle and tighten screw.

6. Check for outlet temperature.

Pressure Differential between Hot & Cold Water Supplies must be

less then 25%.

It is recommended that shutoff valve(s) be installed on the inlet(s) to

facilitate service of the LFLM495 valve.

Repair Kit

n

Troubleshooting

n

Fluctuating or erratic hot water temperature at fixture:

Unbalanced pressure. Install balancing or throttling valve at the hot and

cold water supplies and adjust accordingly for demand.

Hot water backing up into cold water line:

Hot water pressure is higher than cold water pressure.

Examine check valves for dirt & debris, clean as necessary.

Cannot adjust water temperature to desired temperature:

Install balancing or throttling valve at the hot and cold water supplies

and adjust accordingly for demand.

High pressure drop through the tempering valve:

Valve undersized. Install larger thermostatic tempering valve.

Insufficient hot water during peak demand:

Check flow requirement during peak demand period. Use larger

thermostatic tempering valve.

Turn

Hotter

Hex Wrench

Colder

Unscrew, Lift Cap

to Adjust

Figure 3.

Model

Part #

Description

LFLM495

495 100

Plunger/Motor Assembly

Warranty

n

The Seller warrants that the equipment manufactured by it and covered by this order or contract is free from defects in material and workmanship and, without

charge, equipment found to be defective in material or workmanship will be repaired, or at Seller’s option replaced F.O.B. original point of shipment, if written

notice of failure is received by Seller within one (1) year after date of shipment (unless specifically noted elsewhere), provided said equipment has been properly

installed, operated in accordance with the Seller’s instructions, and provided such defects are not due to abuse or decomposition by chemical or galvanic action.

THiS ExprESS wArrAnTy iS in liEu OF And ExcludES All OTHEr wArrAnTiES, guArAnTEES, Or rEprESEnTATiOnS, ExprESS OF impliEd. THErE ArE

nO impliEd wArrAnTiES OF mErcHAnTABiliTy Or OF FiTnESS FOr A pArTiculAr purpOSE. The Seller assumes no responsibility for repairs made on the

Seller’s equipment unless done by the Seller’s authorized personnel, or by written authority from the Seller. The Seller makes no guarantee with respect to material

not manufactured by it.

WARNING: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

For more information: www.watts.com/prop65

1. Mark pipe as shown.

This is pipe insertion depth.

2. Clean pipe end.

1. Remove collet clip.

2. Depress collet.

3. Pull tubing from tailpiece.

3. If using PEX tubing, insert pipe

stiffener (provided) into end of

pipe.

4. Push tubing into tailpiece up to

mark.

5. Insert collet clip.

To Connect

To Disconnect

PEX tubing only

Pipe Stiffener

Tail Piece

Mark

Collet clip

Collet depressed

1

1

⁄

2

in. (38.1mm)

1

3

⁄

4

in. (44.45mm)

1

7

⁄

8

in. (47.63mm)

1

⁄

2

in.Pipe (12.7mm)

3

⁄

4

in.Pipe (19.05mm)

1 in.Pipe (25.4mm)

Quick-Connect Installation

n

NOTICE

NOTICE

WARNING

!

For valves with CPVC or PEX end connections, do not exceed

the tubing manufacturers pressure and temperature ratings.

Refer to the tubing manufacturers product specifications for that

information.

USA: Tel: (800) 669-5430 • Fax: (847) 229-0526 • powerscontrols.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068

•

powerscontrols.ca

Latin America:

Tel: (52) 81-1001-8600 • powerscontrols.com

IS-P-LM495 1427

EDP# 6511208

© 2014 Powers

A Watts Water Technologies Company