Powers LM495 Series Thermostatic Tempering Valves for Individual Lavatory Installations User Manual

Installation instructions

Installation

n

1. Locate suitable place for the tempering valve. Valves should

be accessible for service and adjustment, and be as close to

the point of use as possible.

2. Bleed pressure from the system.

3. Route copper tubing or piping to fit valve dimensions.

4. For valves with Quick-Connect tailpieces refer to “Quick-

Connect Installation” instructions below.

5. Remove tailpieces from the valve and make sure union nuts

are over the tubing/piping before connecting to the tailpiece.

If soldering, remove unions and gaskets from valve body prior to

soldering to prevent damage to valve from excessive heat.

6. Flush piping again, install valve using filter gasket on

hot and cold water inlets and fiber gasket on mixed

water outlet.

7. Turn on the cold and hot water. If any leaks are observed,

tighten connections as necessary to stop leak

before proceeding.

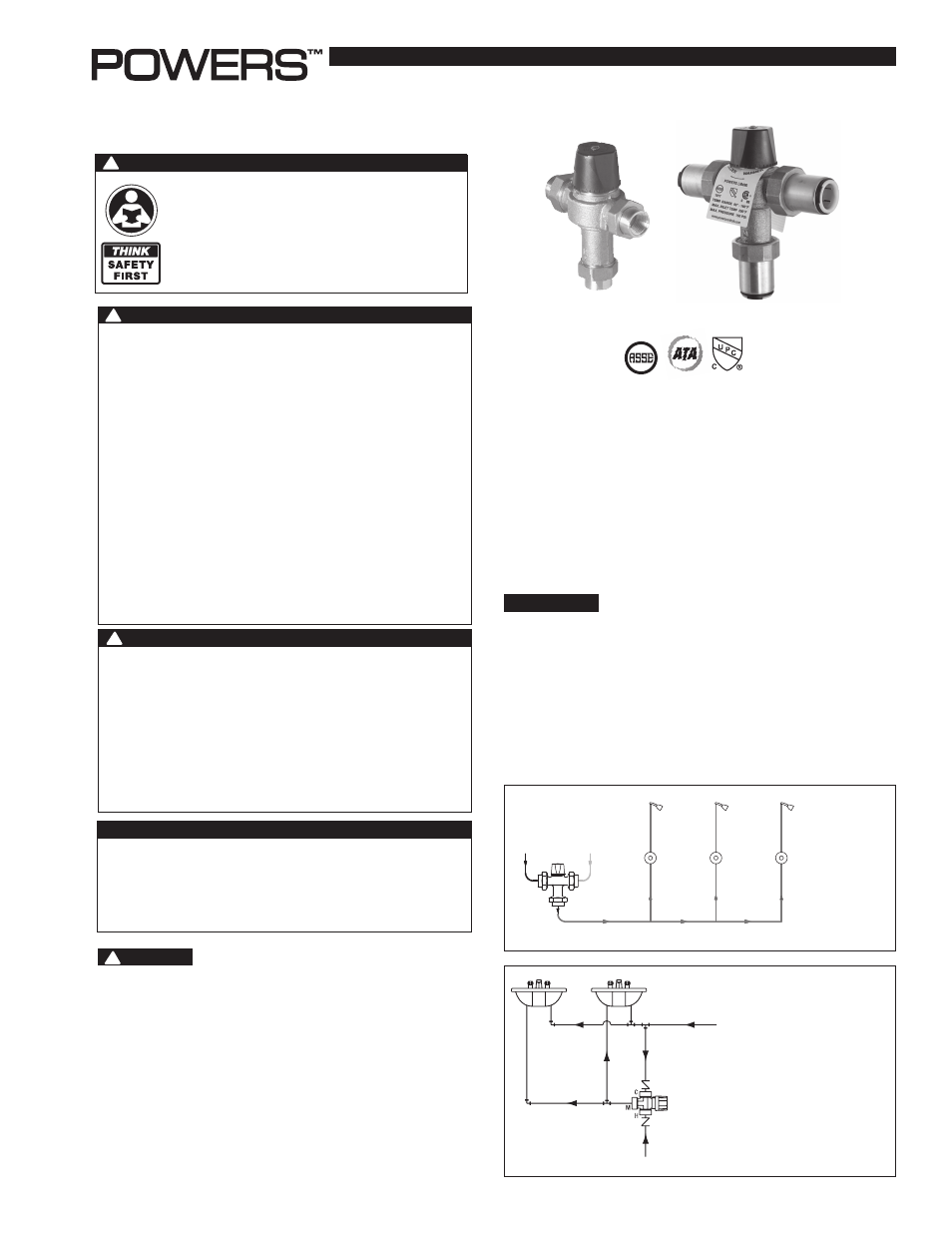

HydroGuard

®

Thermostatic Tempering Valves

LFLM495

IS-P-LM495

Figure 1.

Typical

ASSE 1069

Application

Cold

Hot

LFLM495

Mixed

LFLM495-1

LFLM495-5

COLD WATER

SUPPLY

POWERS SERIES LM495 OR

LFLM495 WITH INTEGRAL

CHECKS AND SCREENS

HOT WATER SUPPLY

Figure 2.

Single/Two

Handle Faucet

Application

Advanced

Thermal Activation

WARNING

!

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use infor-

mation can result in death, serious personal injury,

property damage, or damage to the equipment.

Keep this Manual for future reference.

FAILURE TO COMPLY WITH PROPER INSTALLATION

AND MAINTENANCE INSTRUCTIONS COULD

CONTRIBUTE TO THE VALVE FAILURE, RESULTING IN

INJURY AND/OR DEATH.

TO ENSURE THE ACCURATE AND RELIABLE OPERATION

OF THIS PRODUCT, IT IS ESSENTIAL TO:

• Properly design the system to minimize pressure and

temperature variations.

• This valve is not factory preset and can be adjusted

to deliver scalding temperatures. Check outlet tem-

perature to ensure it does not exceed 105°F (41°C).

Make sure temperature limit stop is properly re-set to

maximum 105°F (41°C) following valve maintenance or

repair. Tampering with limit stop in any way may result

in scalding temperature causing serious bodily harm

and/or death.

WARNING

!

WARNING

!

Need for Periodic Inspection and Yearly Maintenance:

Periodic inspection and yearly maintenance by a licensed

contractor is required. Corrosive water conditions

and/or unauthorized adjustments or repair could render

the valve ineffective for service intended. Regular checking

and cleaning of the valve’s internal components and check

stops helps assure maximum life and proper product func-

tion. Frequency of cleaning and inspection depends upon

local water conditions.

You are required to consult the local building and plumbing

codes prior to installation. If the information in this manual is

not consistent with local building or plumbing codes, the local

codes should be followed. Inquire with governing authorities for

additional local requirements.

WARNING

!

WARNING

!

NOTICE

Flush all pipes thoroughly before installation. Installation and

field adjustment are the responsibility of the installer.

Installation Instructions