Installation instructions (cont.), Preventative maintenance, Safety guidelines – Powers 720 Series VisuGuard T/P Combination Tempering Valve with LCD Temperature Display User Manual

Page 3

Installation Instructions (Cont.)

n

3

HIGH TEMP. STOP

STEM

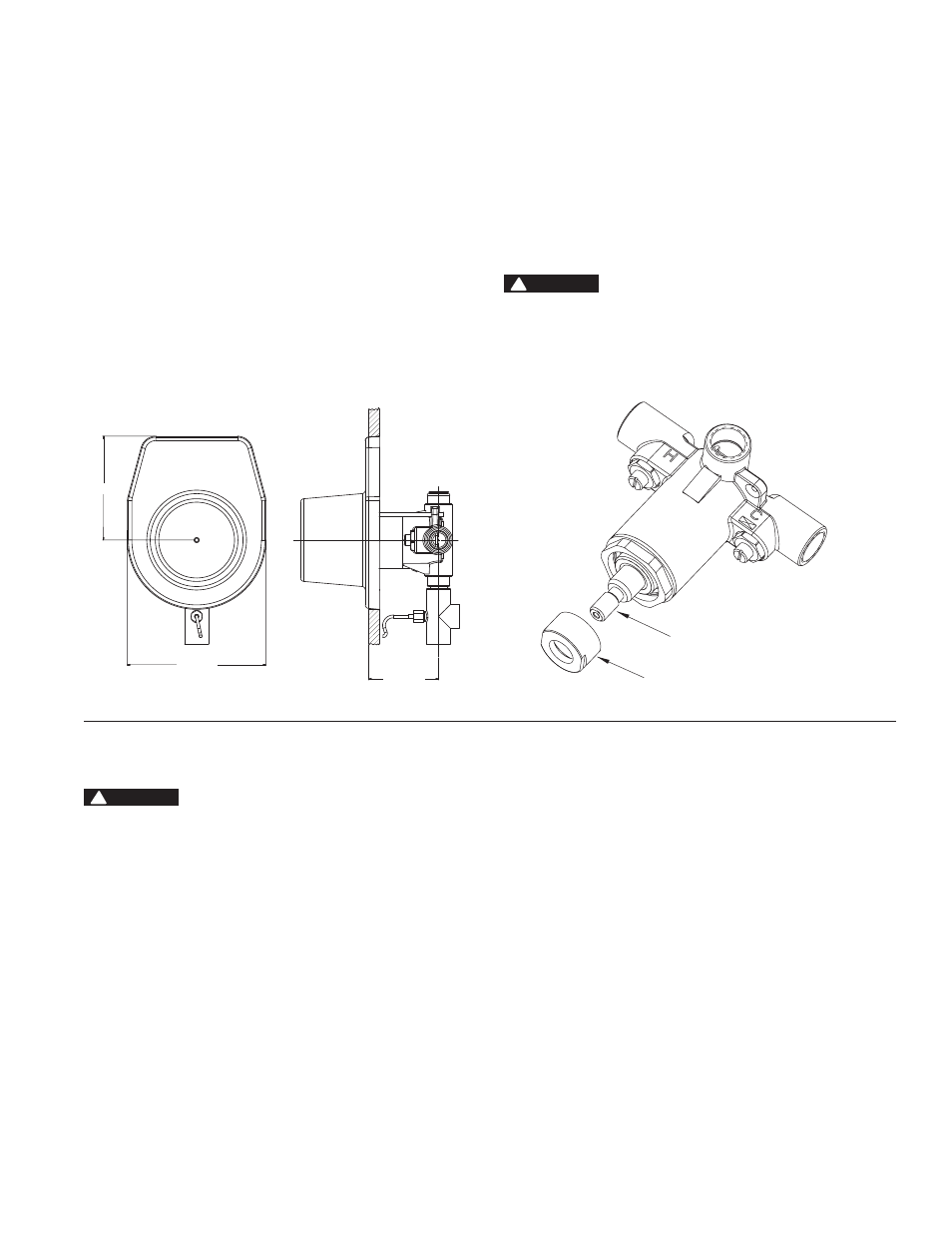

Figure 5

1-5/8 ±.25"

5 [127]

3-3/4 [95]

vis-ewb-front-and-side-with-rough-in-guide

Figure 4

3 3/4 (95)

5 (127)

1 5/8 (25)

Thermistor Assembly

7. Locate and insert the thermistor (temperature probe) into the sup-

plied compression outlet. See Figure 3 for the probe depth. Improper

installation of depth probe can result in imprecise temperature read-

ings. Firmly tighten to prevent leakage. Do not hang trim plate on

wall using temperature probe wire as this could cause damage to

probe. Pressurize and test the system to verify zero leakage.

8. When piping installation is completed and before doing the finished

wall, slide rough-in guide on to the valve stem and press fit into place

(Figure 4). The rough-in guide will ensure the proper size opening for

valve, shutting off checkstops and and repair accessibility.

9. Attach indicator gasket to the back of the trim plate making sure

diagonal holes on the gasket matches diagonal holes on the trim

plate and locator hole matches the top hole on the trim plate. Peel

off backing of the trim plate gasket and attach to the inside top edge

of the trim plate.

10. Install trim plate.

11. Maximum Temperature Setting

Maximum temperature setting adjustment (see Figure 5) must be set

on the job and in no case it should be greater than 110°F (43°C). The

high temperature limit stop is located on the bonnet. Rotate handle

to the maximum desired outlet temperature. With an open-end

wrench, screw high temperature limit stop into the bonnet until it

touches stem's shoulder. Close valve and open it to full hot position

to verify setting.

12. Snap on the indicator plate. Guide on the back of the plate goes into

the locator hole.

13. Install sleeve O-ring on the bonnet. Slide sleeve on the bonnet.

Indicator plate must be installed before sleeve.

14. Install handle and tighten the setscrew.

CAUTION

!

Preventative Maintenance

n

Before servicing checkstops, always turn off the upstream water sup-

ply. When servicing valve, turn off water supply upstream or close the

checkstops.

Every Three Months:

1. Check the maximum temperature setting. Refer to Step 11 of instal-

lation instruction section.

Every Twelve Months

1. Open up the checkstops and check for the free movement of the

poppet. To access the checkstop, remove the handle and trim

plate.

2. Remove the valve bonnet and rinse all grit and impurities from the

cartridge.

Winterize valves that are used outdoors. Remove and store the internal

components and drain all water from the valve.

Safety Guidelines

n

Adherence to these guidelines and recommendations promotes safe

product use and ensures proper valve performance.

1. Thermostatic valves are control devices which must be cleaned

and maintained on a regular basis. Powers specifies periodic main-

tenance at least once a year or immediately after any changes are

made to the plumbing system. Annual cleaning is recommended,

however, frequency of cleaning depends on quality of local water

conditions.

2. The high temperature limit stop setting must be adjusted to limit the

distance the user can rotate the handle towards the full hot water

position.

WARNING

!