Powers 595 Series 11 Self-Operating Temperature Regulators - Type DB & DS Double Seat, Balanced User Manual

Page 9

Testing The Thermal System

■

If the valve is not responding to temperature change,

test the thermal system.

1. Stop the flow of fluid through the line.

2. DA: Raise the temperature of the bulb above the set point

temperature by placing it in a container of hot water. This

will cause the plug to fully seat.

RA: Raise the temperature of the bulb above the set point

temperature by placing it in a container of hot water.

This will cause the plug to fully open.

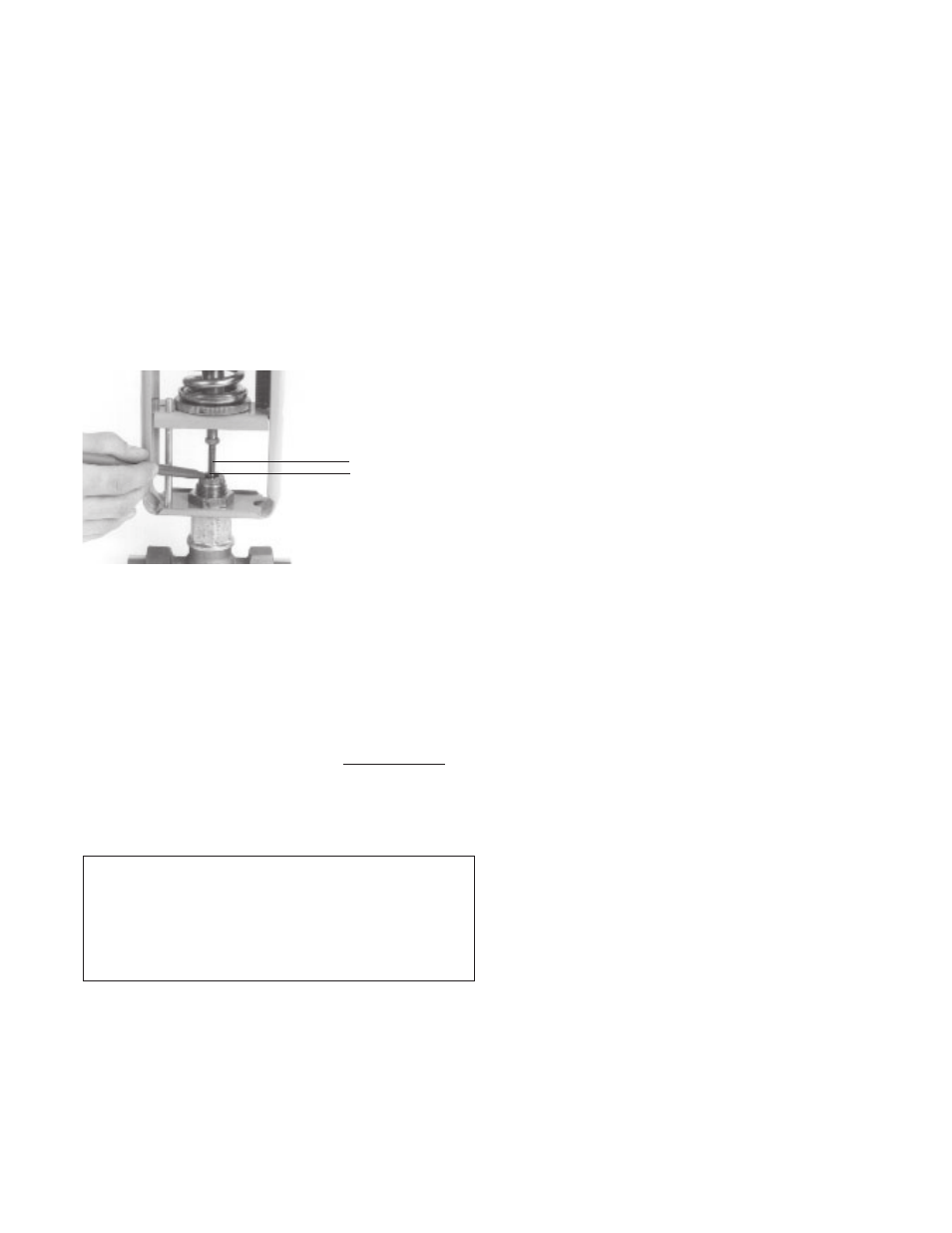

3. Figure 15. With the valve plug in the desired position, use

a felt tip pen to mark the position of the packing gland

assembly on the stem.

4. DA: Place the bulb in a pan of cool water. Cool the bulb 30°F

(16°C) below set point so the valve is fully open.

RA: Place the bulb in a pan of cool water. Cool the bulb to or

beyond the set point so the valve plug is seated.

5. Use the pen to mark the new position of the packing gland

assembly on the stem.

6. The distance between the marks is the valve plug travel.

This should correspond with the TRAVEL value in the VALVE

DIMENSIONS table on page 14. No movement or only partial

movement indicates the thermal system is defective and

should be replaced with a new system.

WARNING:

Failure of the #11's thermal system will cause a heat-

ing valve to full open and a cooling valve to full close.

If either of these valve states results in an unsafe process

condition, a high-limit shutdown device, such as a Powers

AquaSentry, should be used.

15. Valve travel

Distance between two

marks = Valve Travel

9