Product identifi cation, Installation – Powers 595 Series 11 Self-Operating Temperature Regulators - Type DB & DS Double Seat, Balanced User Manual

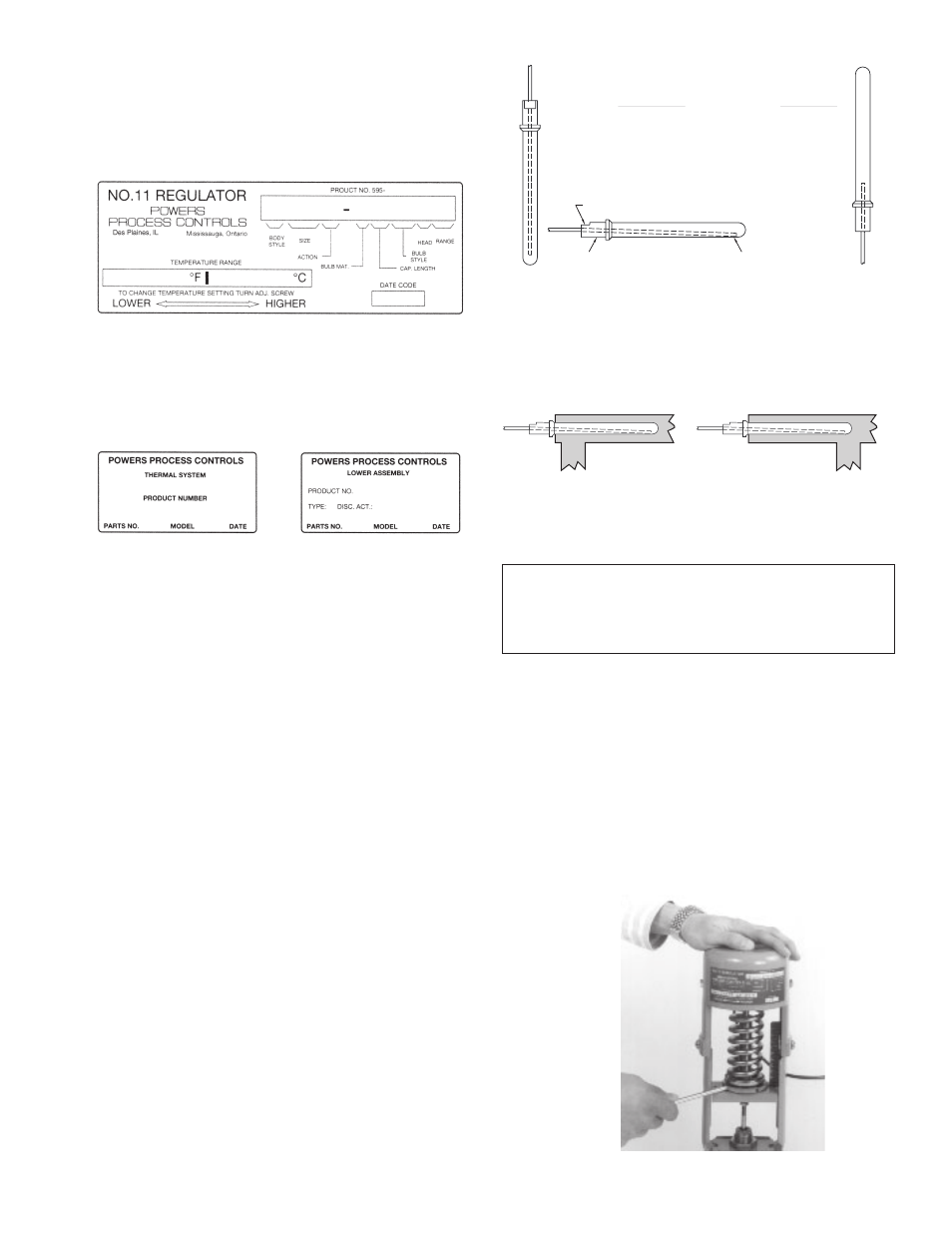

Page 5

Adjust Capillary Tubing

6. Coil the extra capillary, and position away from regulator

operation where it is subjected to room temperature only.

Adjust set point

All regulators are factory set to control near mid-range

operating temperature.

WARNING: DO NOT kink, cut, sever or fi le the tubing.

DO NOT disconnect tubing from bulb or bellows assembly.

This can render the thermal system inoperable and result in

severe process overheating.

7. When adjusting the set point, make certain the heating or

cooling medium is fl owing through the valve and is at the

operating pressure of the system.

8. Figure 5. Make all set point temperature changes by insert-

ing the temperature adjustment rod into one of the holes of

the adjusting nut assembly. (Use the temperature adjustment

setting scale only for reference)

To Raise The Set Point: Turn rod left to right

(counterclockwise from top).

To Lower The Set Point: Turn rod right to left

(clockwise from top).

Product Identifi cation

■

legs (Figure 2A) or the valve body vertical yoke (Figure 2B).

When replacing the original thermal assembly or valve body,

secure the old red label onto the valve or thermal system or ink

the number onto the body.

1. Product label

A red label should be on the front face of the thermal system,

(Figure 1.) This label contains information required to properly

maintain, service and order parts for this product. If there is no

label, look for a white label on the inside of the thermal system

2

A

. Thermal system label

2

B

. valve body label

Installation

■

Tools Needed

• Straight slot screwdriver

• 5/16" open end wrench

• 3/8" open end wrench

• 7/16" open end wrench

• 13/16" open end wrench

• 1-3/8" open end wrench

Position Valve

1. To insure proper system operation, thoroughly fl ush all piping

and valves to rid them of all scale, dirt and debris.

2.

Select valve location with suffi cient clearance to allow

maintenance. Install valve in line. The direction of the arrows

on the valve body must match the direction of the water or

steam fl ow.

For best results, we recommend installing the valve in a

horizontal line, and in the upright position with bellows head

above valve. The valve may also be installed in any position

within 90° of upright.

Install Bulb

3. Figure 3A shows proper bulb orientation. Figure 3B shows

the special bulb needed for upwards vertical positioning.

4. Figure 4 For any position, fully immerse the bulb in the fl ow

of the medium.

These instructions are for D style bulbs - for installation of

other styles, refer to tag attached to bulb.

5. Without a well: Remove bushing from the bulb and screw it

into the tank. Insert the thermostatic bulb through the bush-

ing and tighten the union nut.

With a well: Do not use bushing. Screw well into tank, insert

bulb directly into well, and tighten union nut.

WORD "TOP" ON FLAT SURFACE FACING UP

HEAD

END

TOP

Standard Bulb

Downward Vertical (left)

or

Horizontal (below)

Only

Special Bulb

Upward Vertical

Only (right)

3

B

. special bulb

3

A

. bulb orientation

Correct: Bulb in flow of medium

Incorrect: Bulb not in flow of medium

4. bulb position

5. adjusting set point

5