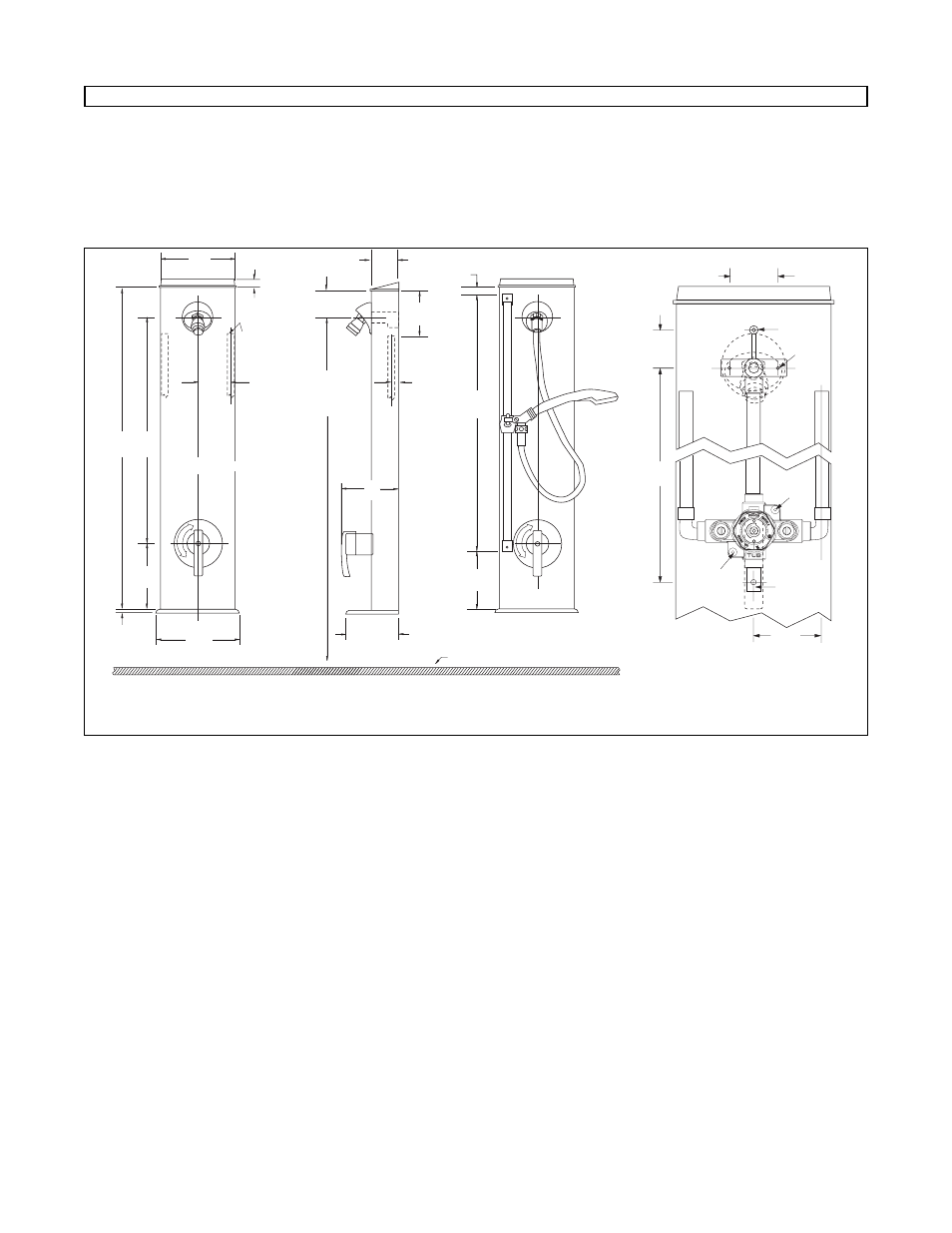

Installation, Figure 4 – Powers 450-900 HydroPanel II Shower System with Biltmore 900 Pressure Balancing Valve User Manual

Page 2

TI450-900

Page 2

Before installation of any Hydropanel II unit, rotate the stem (or

handle if attached) of the valve to its full clockwise position (OFF).

POSITION THE HYDROPANEL II UNIT

(See Figures 1 and 2) Determine the horizontal position of the unit

according to shower room layout, and mark the centerline.

For multiple shower applications, the recommended minimum

distance between the centerline of two units is 36

"

[1914mm].

1. Determine the floor-to-showerhead height for the unit.

Recommended heights are listed below:

Men - 77

"

[1956mm]

Youth - 66

"

[1676mm]

Women - 70

"

[1778mm]

Youth - 60

"

[1524mm]

2. The preassembled copper tubing supply water inlets are

4-1/8

"

[105 mm] from the top of the shroud, and 3-5/16

"

[84mm] left and right of the centerline. Adjust supply

piping accordingly.

Install the Piping Assembly

The valve handle assembly, piping and Hydropanel II shrouding

must be separated before mounting to wall. For #4504004 and

#4504005 Hydropanel II units, the handshower, hose and show-

erhead base come preassembled to the shrouding. Refer to

Figure 4.

3. Detach the valve assembly by removing valve retaining

screw, handle and collar. Undo the screws at D and D

'

and

take off the dial insert.

4. Remove the screw at A above the showerhead. Slide the

piping out of the shrouding; the shower head remains

attached to the shroud.

5. For mounting the piping assembly upper bracket (B), use

the bracket as a template and drill two small holes in the wall

at showerhead height.

6. For mounting the piping assembly lower bracket (C), drill one

small holes in the wall 23-1/2

"

[587mm] below the shower-

head on the centerline.

7. Install any mounting anchors as detailed by the individual

room specifications.

8. Secure upper piping bracket B with mounting screws

(not included).

9. Secure lower piping bracket C with mounting screw (not

included).

10. Connect the supply lines to the piping assembly.

Attach the Shrouding

Do Not remove the entire chrome plated end cap from the

shrouding; it functions as an end cap and gasket for shroud

extension. Part of the end cap can be broken out to provide verti-

cal and horizontal piping clearance.

10. To remove scored section, hit it sharply with a hammer.

11. To connect the showerhead on the shroud to the water out-

let pipe, slide the showerhead nipple on the inside of the

shroud into the piping assembly. The End Cap will slide over

the supply piping. Secure the shrouding with the screw at A.

Test the System

Before final assembly, test the Hydropanel II system.

12. Fit the handle onto the valve stem and turn clockwise to the

shut off position.

13. Turn on water supply, and then rotate the valve handle

counterclockwise. Water should come through the shower-

head.

14. Now turn handle fully counterclockwise and measure the

temperature of the outlet water. Wait until the temperature

stabilizes for an accurate reading.

15. Turn off valve (fully clockwise) and check all connections

(showerhead, pipe connections, valve bonnet) for leaks.

INSTALLATION

HO

T

C

OL

D

OFF

7-1/2"

[191]

7-3/32"

[180]

3-5/16"

[84]

C for Hydropanel unit

4-1/8"

[105]

11/16"

[18]

L

OFF

24"

[610]

4-3/4"

[121]

HO

T

C

OL

D

1-1/4"

[32]

2-1/2"

[64]

4-3/4"

[121]

FLOOR LINE

6"

[152]

7/16"

[11]

30"

[762]

6"

[154]

21-1/4"

[540]

1/2"

Copper Inlets

1/2"

[13]

For Suggested

Showerhead

Height see

General

Installation

2-3/4"

[70]

Figure 1:

Front dimensions

Hydropanel II Model 4504000

Figure 2:

Side dimensions

Hydropanel II Model 4504000

Figure 3:

Front dimensions

Hydropanel II Model 4504004.

3-5/16"

[84]

23-1/2"

[597]

A

C

D'

D'

B

END CAP

1-3/4"

[44]

2-1/4"

[57]

Figure 4.