Watts W100T Twin Alternating Series User Manual

Page 44

44 W100T Twin Alternating Series Softeners

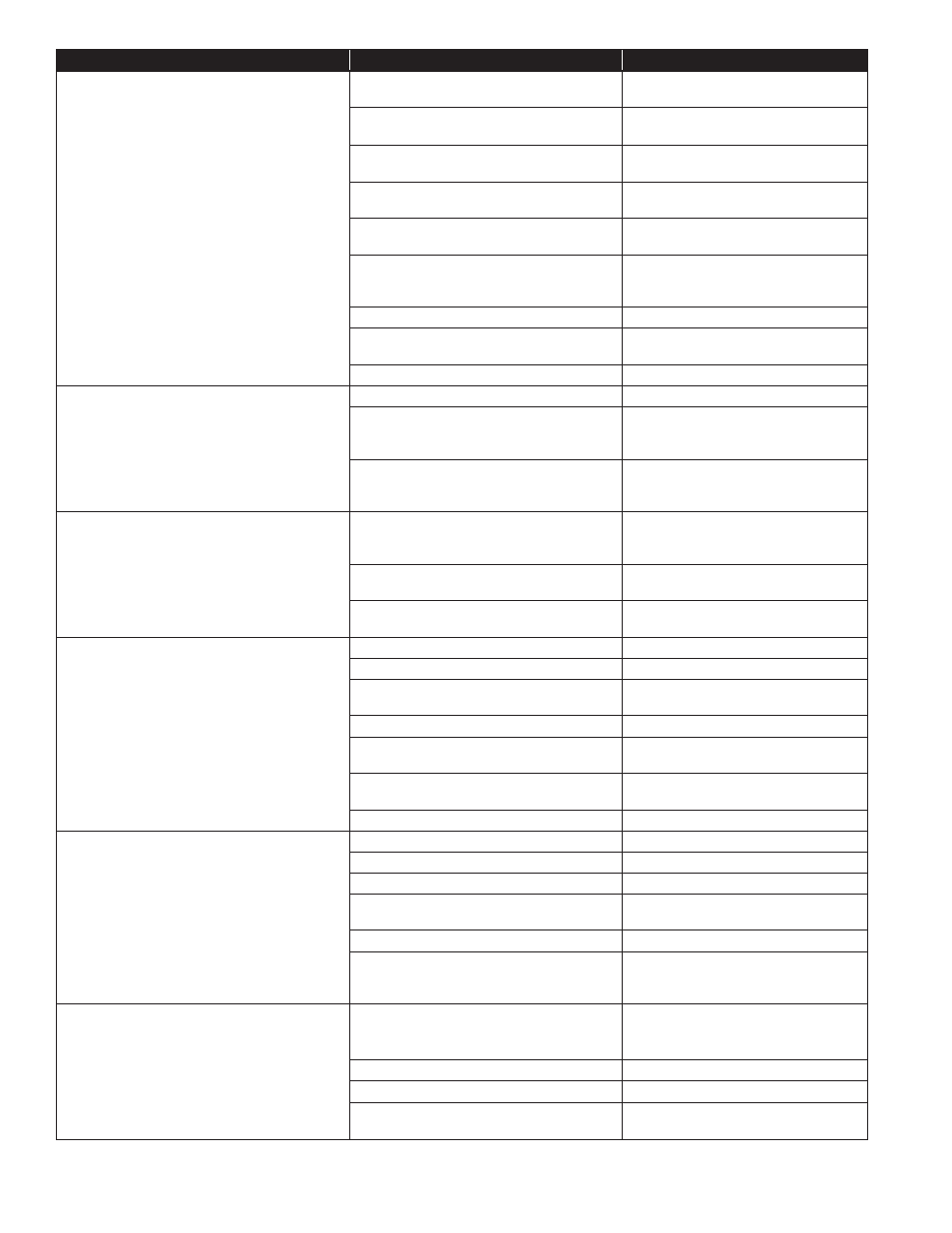

Problem

Possible Cause

Solution

8. Hard or untreated water is being delivered

a. Media is exhausted due to high water

usage

a. Check program settings or diagnostics

for abnormal water usage

b. Meter not registering

b. Remove meter and check for rotation

or foreign material

c. Water quality fluctuation

c. Test water and adjust program values

accordingly

d. No regenerant or low level of regenerant in

regenerant tank

d. Add proper regenerant to tank

e. Control fails to draw in regenerant

e. Refer to Trouble Shooting Guide

number 12

f. Insufficient regenerant level in regenerant

tank

f. Check refill setting in programming.

Check refill flow control for restrictions

or debris and clean or replace

g. Damaged seal/stack assembly

g. Replace seal/stack assembly

h. Control valve body type and piston type

mix matched

h. Verify proper control valve body type

and piston type match

i. Fouled media bed

i. Replace media bed

9. Control valve uses too much regenerant

a. Improper refill setting

a. Check refill setting

b. Improper program settings

b. Check program setting to make sure

they are specific to the water quality

and application needs

c. Control valve regenerates frequently

c. Check for leaking fixtures that may

be exhausting capacity or system is

undersized

10. Residual regenerant being delivered to

service

a. Low water pressure

a. Check incoming water pressure

– water pressure must remain at

minimum of 25 psi

b. Incorrect injector size

b. Replace injector with correct size for

the application

c. Restricted drain line

c. Check drain line for restrictions or

debris and clean

11. Excessive water in regenerant tank

a. Improper program settings

a. Check refill setting

b. Plugged injector

b. Remove injector and clean or replace

c. Drive cap assembly not tightened in

properly

c. Re-tighten the drive cap assembly

d. Damaged seal/ stack assembly

d. Replace seal/ stack

e. Restricted or kinked drain line

e. Check drain line for restrictions or

debris and or straighten drain line

f. Plugged backwash flow controller

f. Remove backwash flow controller and

clean or replace

g. Missing refill flow controller

g. Replace refill flow controller

12. Control valve fails to draw in regenerant

a. Injector is plugged

a. Remove injector and clean or replace

b. Faulty regenerant piston

b. Replace regenerant piston

c. Regenerant line connection leak

c. Inspect regenerant line for air leak

d. Drain line restriction or debris cause excess

back pressure

d. Inspect drain line and clean to correct

restriction

e. Drain line too long or too high

e. Shorten length and or height

f. Low water pressure

f. Check incoming water pressure

– water pressure must remain at

minimum of 25 psi

13. Water running to drain

a. Power outage during regeneration

a. Upon power being restored control will

finish the remaining regeneration time.

Reset time of day.

b. Damaged seal/ stack assembly

b. Replace seal/ stack assembly

c. Piston assembly failure

c. Replace piston assembly

d. Drive cap assembly not tightened in

properly

d. Re-tighten the drive cap assembly