Watts LF800M4QT User Manual

Sizes, Testing

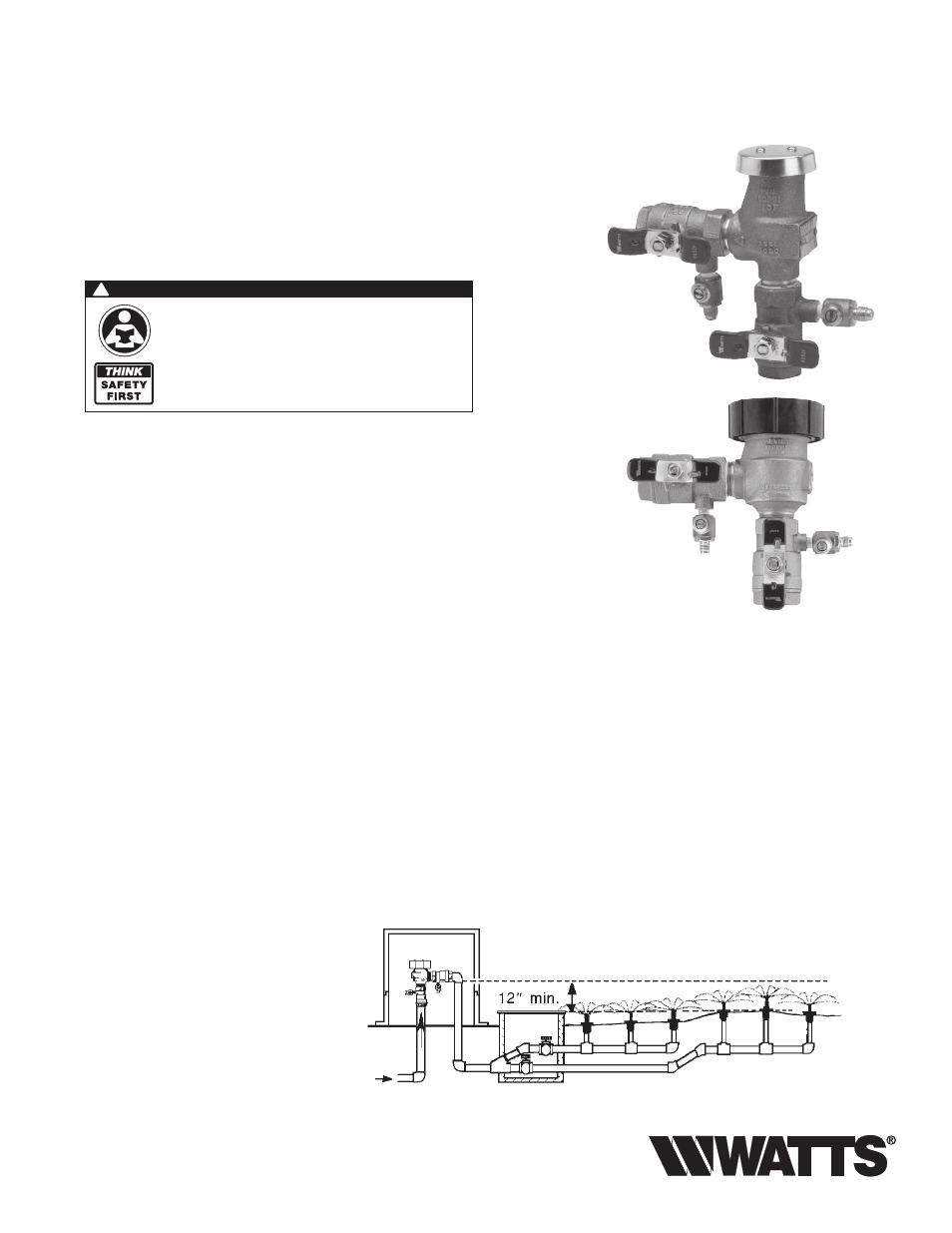

Models: 800M4FR, 800M4QT, LF800M4FR, LF800M4QT

Installation

Requirements:

1. Install 12" (305mm) above highest point of downstream piping

see Fig. 1.

2. Install bonnet side up and allow for accessibility for testing/service.

3. Install where discharge or spillage is not objectionable.

4. Do not undersize supply or oversize the valve in relation to demand.

5. Do not install where backpressure can occur.

6. Protect from freezing - for Freeze Protection specify Model 800M4FR or

LF800M4FR. Freeze protection can also be provided using a WattsBox

insulated enclosure. Send for ES-WB for additional information.

7. ASSE Standard 1020 requires that the atmospheric vent valve remains

open until the valve body pressure exceeds 1 lb. Until this pressure is

reached, some amount of spillage will occur at the atmospheric vent.

In order to minimize this leakage on

start-up close the down stream

shutoff valve and open inlet shutoff valve quickly.

Service:

1. Open test cocks to drain in cold climates if only operated seasonally.

2.

Replace rubber goods every 5 years.

Watts 800M4QT/

LF800M4QT

1

⁄

2

",

3

⁄

4

" (15, 20mm)

Watts 800M4QT/

LF800M4QT

1" - 2" (25 - 50mm)

RP/IS-800M4QT

Installation, Maintenance, & Repair

Series 800M4 and LF800M4

Anti-Siphon Pressure Vacuum Breaker

featuring Replaceable Seats

Sizes:

1

⁄

2

" - 2" (15 - 50mm)

Pressure — Temperature

Working Temperature: 33°F - 140°F (0.5°C - 60°C)

Maximum Pressure: 150psi (10.3 bar)

Minimum Pressure: 15psi (103 kPa)

WattsBox

Fig. 1

Testing

For field testing procedure, refer to Watts installation sheets

IS-TK-DP/DL, IS-TK-9A, IS-TK-99E and IS-TK-99D found on

www.watts.com.

For other repair kits and service parts, refer to our Backflow

Prevention Products Repair Kits & Service Parts price list

PL-RP-BPD found on

www.watts.com.

For technical assistance, contact your local Watts representative.

Local building or plumbing codes may require modifications to the

information provided. You are required to consult the local building and

plumbing codes prior to installation. If this information is not consistent

with local building or plumbing codes, the local codes should be fol-

lowed.

Need for Periodic Inspection/Maintenance: This product must be

tested periodically in compliance with local codes, but at least once per

year or more as service conditions warrant. Corrosive water conditions,

and/or unauthorized adjustments or repair could render the product

ineffective for the service intended. Regular checking and cleaning of the

product’s internal components helps assure maximum life and proper

product function.

WARNING

!

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.