Servicing transfer cap assemblies (continued) – Watts W100T Twin Alternating Series User Manual

Page 42

42 W100T Twin Alternating Series Softeners

NOTE: That both transfer caps only mount in one orientation. Prior to installation of cap assembly be sure to check that the

stainless steel spring and the plastic spring support is in place attached to the inside of the cap assembly. Next you can

wipe the outside edge of the O-ring on the cap and the inside mating area of the valve with a clean cloth & re-apply a thin

layer of silicone lubricant like Dow #7.

BE SURE NOT TO USE ANYTHING HYDROCARBON BASED SUCH

AS VASELINE OR PETROLEUM JELLY TO LUBRICATE PLASTIC

COMPONENTS OR O-RINGS AS THEY WILL BE DAMAGED BY

THE HYDROCARBONS AND POTENTIALLY CAUSE FAILURES

THAT CAN RESULT WITH LEAKS.

Noting the one possible orientation of the transfer drive cap, use one hand to press in and support the transfer drive cap while using the

opposing hand to start two screws in, one on the top and one opposing it on the bottom. Tighten the screws in evenly so the cap seats

the O-ring without getting pinched or damaged. Screws should only be hand tightened with a 5/32” or 4mm allen wrench,

DO NOT OVER

TIGHTEN SCREWS.

Be careful and make sure the meter cable doesn’t get under the drive cap

while tightening as it will result in damaging the cable.

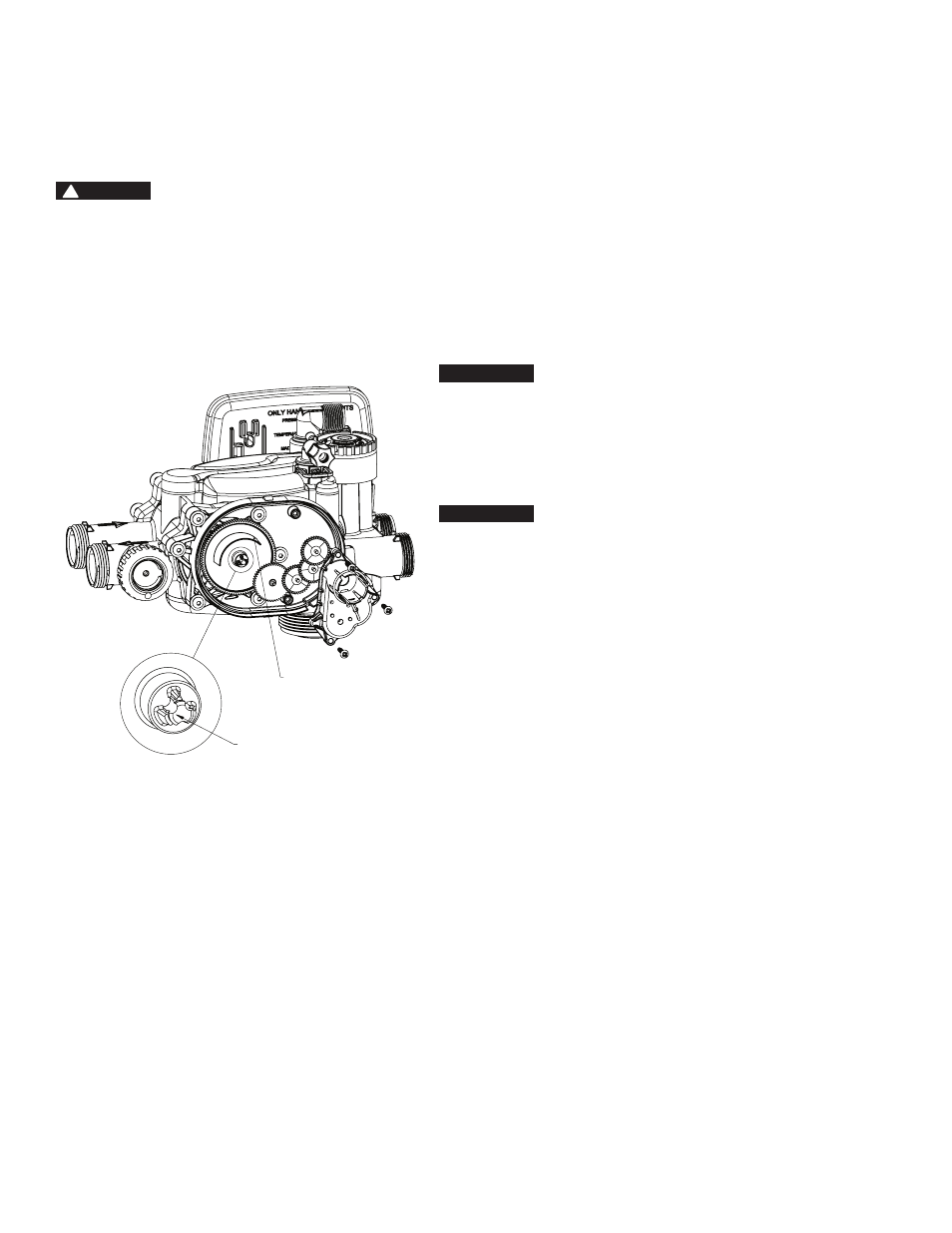

Position the large white drive gear with the “A” pointing toward the 1

o’clock position and then press it onto the stainless steel drive shaft, make

sure it snaps & locks into position.

The white drive gear is splined to the drive shaft and will only assemble in

one orientation. Because of this it is not necessary that the discs and gear

be exactly positioned, the positioning needs to be approximate but they

have to fit on the shaft.

Next install the larger black reducing gear onto the stainless steel shaft,

then install the remaining smaller reducing gears from left to right. Re-install

the grey reducing gear cover over the gears and affix with the 3 stainless

steel screws. Now you can re-install the drive motor by pressing the spring

clip loop to the right then rotate the motor as you are inserting it so the

gear of the motor meshes properly with the reducing gears. Release the

spring clip loop and rotate the motor untill the motor housing engages with

the plastic nub inside the housing that holds the motor in place and make

sure that the top of the motor is flush with the top of the grey gear housing.

Press the drive motor wires down into the strain relief of the drive cap, now

you can re-install the cover assembly.

NOTE: After completing any valve maintenance involving the valve drive assembly or the transfer drive assembly please press

and hold the NEXT & the REGEN buttons simultaneously for 3 to 5 seconds to perform a soft reset which will synchronize

the control valves positions.

"A" text orientated

towards 1 o'clock

Splines can only

fit one direction

on shaft.

Servicing Transfer Cap Assemblies (continued)

NOTICE

CAUTION

!

NOTICE