Servicing transfer cap assemblies – Watts W100T Twin Alternating Series User Manual

Page 41

W100T Twin Alternating Series Softeners

41

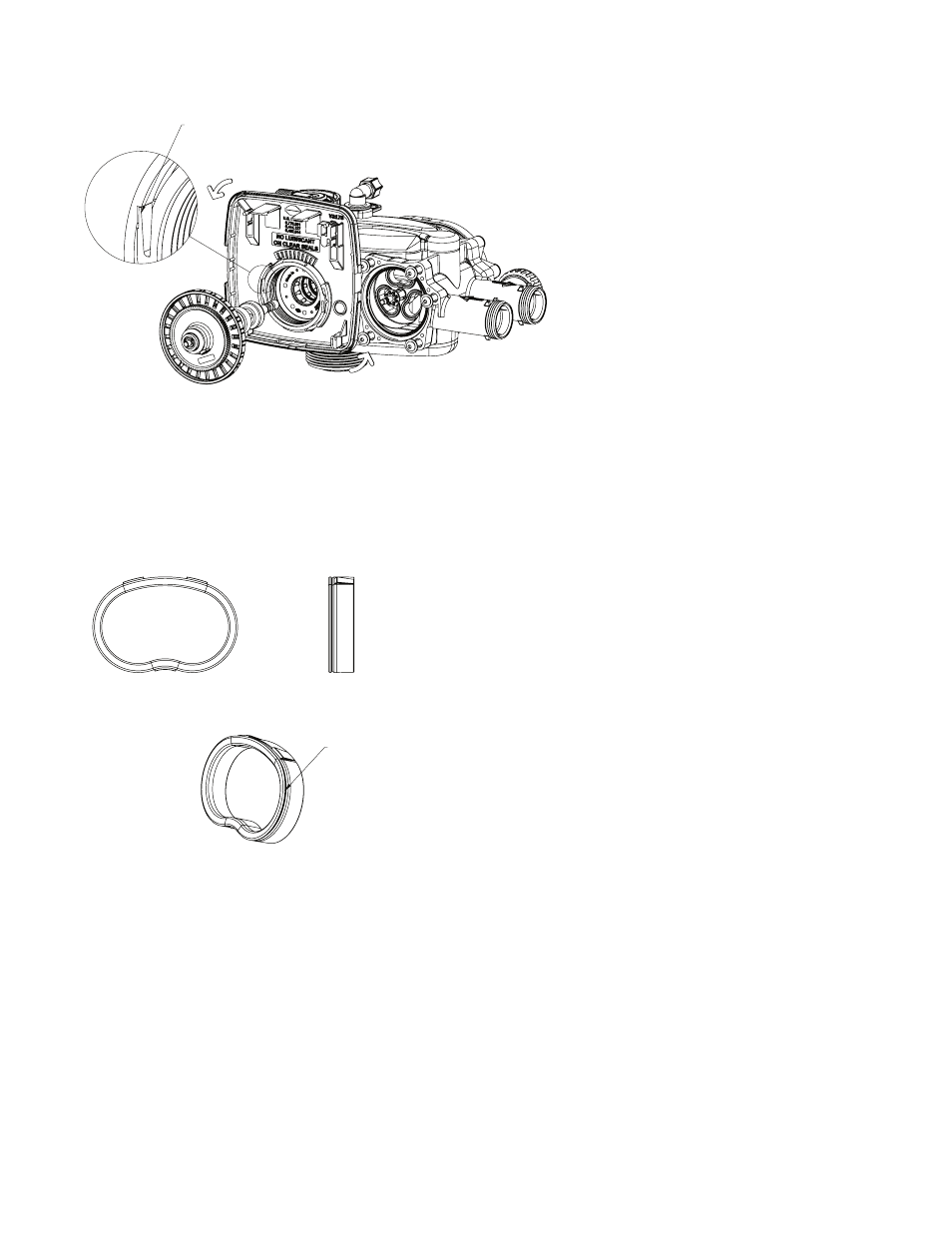

Servicing Transfer Cap Assemblies

The control valves backplate must be removed first to

allow access to removing the transfer cap assembly.

Hold slight downward pressure on the top left corner of

the backplate while using a thin flat screwdriver or knife

blade to push in on the locking tabs, this will release

the backplate and it will twist to the left off of the valve

body. For removal of the drive motor side you will need to

remove the drive cover assembly to access the motorized

drive. The drive motor can be removed by pressing the

spring clip loop to the right then rotate the motor a ¼ turn

and pull outward to remove the motor from the reducing

gear cover assembly. Remove the three Phillips head

stainless steel screws that retain the reducing gear cover

to the drive cap. Once the cover is removed you have

access to the reducing drive gears simply slide them off

of the gear axles with your fingers to inspect / check them

there are 3 small black gears with foil decals and 1 larger

black reducing gear. Remove the large white drive gear

from the stainless steel drive shaft. To remove the large white transfer drive gear firmly grab the outside edge of the gear with your fingers and

pull it outward away from the control valve assembly. Now you can use a 5/32” or 4mm allen wrench to remove the ¼-20 screws that retain the

transfer drive cap assemblies on both sides of the valve.

Once the screws are removed from retaining the inlet side transfer valve cap and the outlet drive motor transfer cap from the control valve the

cap will spring out away from the valve body. At this point the transfer discs may be removed by pulling the discs outward off of the shaft away

from the valve body with your hand. With the disc out you can inspect the flat surface area to be sure it’s clean and smooth free of any debris

or scratches. Note that the disc is keyed to the drive shaft so that it will only assemble in one orientation. The transfer discs may be chemically

cleaned with a dilute sodium bisulfate solution, vinegar or just wiped with a soft clean cloth.

To remove seals gently pull out on the outer lip of the seal to lift the seal out from its cavity

being careful not to damage the face surface of the seal. To reassemble re-seat seals

into the seal cavity of the control valve body being sure that the lip of the seal is facing

outward. With seals in place put a thin film of Dow #7 on the tops of the seals and the

flat surface of the discs. Prior to reinstalling the discs the drive shaft should be removed

and the O-rings cleaned, inspected and lubricated with Dow #7. The shaft can then be

installed into the disc prior to installation. With the outlet disc assembled to the shaft the

orientation of the shaft to inlet disc can be assured by installing the set with the through

hole on the outlet disc at the 6 o’clock position.

The easiest thing would be to remove both disc drives and assemble the outlet side first.

Then each disc could be fitted on the shaft individually. At this point the transfer valve cap

assemblies can be reinstalled.

Release locking tabs

from each side to

remove back plate.

Seal "Lip"

feature