Duo-touch, Models at-..m-2a two-hand control modules, Caution – Banner DUO-TOUCH Two-Hand Control Modules User Manual

Page 7: Warning

P/N 47550 rev. E

7

DUO-TOUCH

®

– Models AT-..M-2A Two-Hand Control Modules

Banner Engineering Corp.

•

Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Connection of Power to the DUO-TOUCH Safety Module

The Safety Module requires a 24V dc, 115V ac or 230V ac supply voltage (see

Specifications on page 11). Use extreme caution whenever installing ac power. Use a

minimum of 16 to 18 AWG wire for power and output connections. A hand-operated

supply disconnect (e.g. a circuit breaker) must be provided (per NFPA79 and IEC/

EN60204).

Connection to the Machine to be Controlled

Figure 5d shows a generic connection of the Safety Module’s two redundant output

contacts to machine primary control elements MPCE1 and MPCE2. An MPCE is

defined as an electrically-powered element, external to the safety module, which

directly controls the machine’s normal operating motion so that it is the last (in time)

to operate when motion is either initiated or arrested. Some older machines offer only

one MPCE; for such machines, it may be necessary to add a second MPCE to establish

the appropriate level of safety integrity.

The connection of the safety outputs must be in such a manner that the stop command

issued by the AT-..M-2A can not be overridden by a device or circuit that is not at the

same level of safety integrity. This means that the safety outputs are interfaced on

the output of the machine logic (e.g., PLC or PC). Then, normally, a feedback signal

identifies to the machine logic the status of the Safety Module and, if possible, the

status of the MPCEs. If interposing relays are used, they must be of mechanically

linked (forced-guided) design and monitored by the MPCE Monitoring Circuit (X1/X2).

As shown in Figure 5d, a normally-closed, mechanically linked monitor contact from

each of the two MPCEs must be connected in series across terminals X1 and X2.

This allows the Safety Module to monitor the state of the MPCEs, and to prevent a

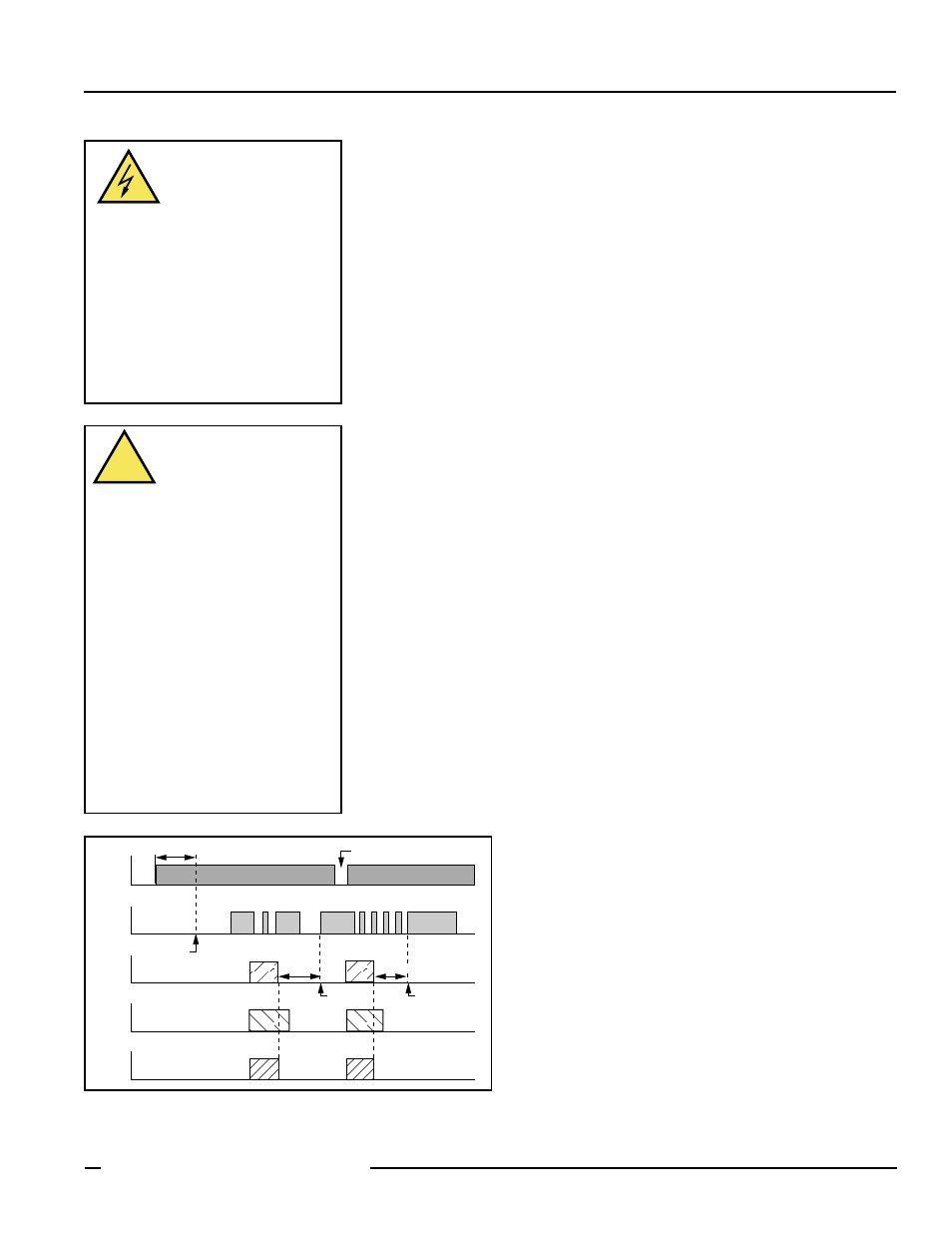

successive machine cycle, if an MPCE fault is detected. There is a timing requirement

associated with the operation of X1 and X2 inputs. The monitoring contacts of external

relays must close within 200 ms following deactivation of the AT-..M-2A outputs. If this

requirement is not met or an internal fault is detected, the unit enters a lockout mode

(indicated by Fault LED ON Red). A power cycle is required to exit the lockout. See

Figure 4 and Caution on page 10.

When MPCE monitor contacts are not available, a jumper wire must be installed

across terminals X1 and X2.

When a jumper wire is used (dotted line between X1 and X2 in Figure 5d), it is the

user’s responsibility to provide an appropriate level of safety for the means of machine

interfacing to ensure that any single MPCE component failure will not result in the loss

of safety.

When switching inductive ac loads, it is good practice to protect

the Safety Module outputs by installing appropriately-sized arc

suppressors. However, if arc suppressors are used, they must

be installed across the load being switched (e. g., across the

coils of external safety relays), and never across the Safety

Module’s output contacts (see WARNING on page 8).

CAUTION ...

Disconnect

Power Before Wiring

Always disconnect all power

from the DUO-TOUCH Safety Module

and the machine being controlled before

making any wire connections.

Electrical installation of hand controls, the

DUO-TOUCH SG Safety Module, and the

interconnection to the machine control

must be made by qualified personnel and

must comply with NEC (National Electrical

Code), ANSI/NFPA79 or IEC60204-1, and

all applicable local standards.

WARNING ...

Use of

Electronic Hand Controls

Electronic (powered) hand controls

include optical touch buttons, capacitive

touch buttons and similar devices. When

electronic hand controls are used as

input switches for a DUO-TOUCH Safety

Module, the hand controls and the Safety

Module must be powered from the same

voltage source. Failure to do so creates

a potentially dangerous condition, which

could result in serious injury or death.

If power is applied to the Safety Module

before power is applied to the electronic

hand controls, an output from the DUO-

TOUCH Safety Module could result and may

trigger machine motion. Also, electronic

hand controls cannot guarantee the state of

their outputs at the time power is applied

to them.

!

Power

Feedback

(X1-X2)

Input 1

Input 2

Output

200 ms

200 ms

200 ms

closed

open

EDM Error

(Red LED ON)

Lockout

No Lockout –

Normal

Operation

Lockout Recovery

Figure 4. X1 and X2 Input timing requirements