Duo-touch, Models at-..m-2a two-hand control modules, Appropriate applications – Banner DUO-TOUCH Two-Hand Control Modules User Manual

Page 3

P/N 47550 rev. E

3

DUO-TOUCH

®

– Models AT-..M-2A Two-Hand Control Modules

Banner Engineering Corp.

•

Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Appropriate Applications

The DUO-TOUCH Two-Hand Control Safety Module may be used as an initiation

device for most powered machinery when machine cycling is controlled by a machine

operator.

Using a two-hand control system makes the operator a “hostage” while the hazard

is present, thus limiting or preventing exposure to the hazard. The two-hand control

actuators must be located in a way that hazardous motion is completed or stopped

before the operator can release one or both of the buttons and reach the hazard (see

Separation Distance on page 6).

Simultaneous use of both hands is required, meaning that both buttons must be

actuated within a very short time span. The time span is specified by ANSI/RIA R15.06,

ANSI/NFPA79, and ISO 13851 (EN 574) as not more than 500 ms, even under single-

fault conditions. This requirement reduces the possibility of intentional defeat and

unintended initiation of the machine cycle.

When used in single-cycle or single-stroke mode, the machine control must provide

an anti-repeat feature so that the operator must release the two-hand control actuators

after each machine cycle, before a new cycle can be initiated.

The actuating devices must be protected from accidental or unintended operation. This

can be accomplished by their mounting position and/or through the use of protective

shields such as rings, guards or shields; see Figure 3.

NOTE: Two-hand control and two-hand trip safeguarding protect only the operator’s

hands. Additional safeguarding may be required. The user must refer to the

relevant standards for additional requirements for the application of two-hand

control and two-hand trip devices when used for safeguarding.

Part-Revolution Clutched Machinery

A two-hand control safety module can be used for the following functions: “inch”

(jog), “single-stroke,” or “continuous” (run). Two-hand control safety modules are

recognized as a means of protecting the machine operator when the hand controls

are safely located and protected from false operation (see Mechanical Installation on

pages 4-5 and Separation Distance on page 6) and when properly interfaced to the

machine (see Electrical Installation on page 7) to control the required stopping action.

Full-Revolution Clutched Machinery

A two-hand control safety module used to initiate the cycle of a full-revolution clutched

machine is known as a “two-hand trip device.” Two-hand trip devices are recognized

as a means of protecting the machine operator when the hand controls are safely locat-

ed and protected from false operation (see Mechanical Installation on pages 4-5 and

Separation Distance on page 6) and when properly interfaced to the machine (see

Electrical Installation on pages 6-7) to prevent accidental cycle initiation.

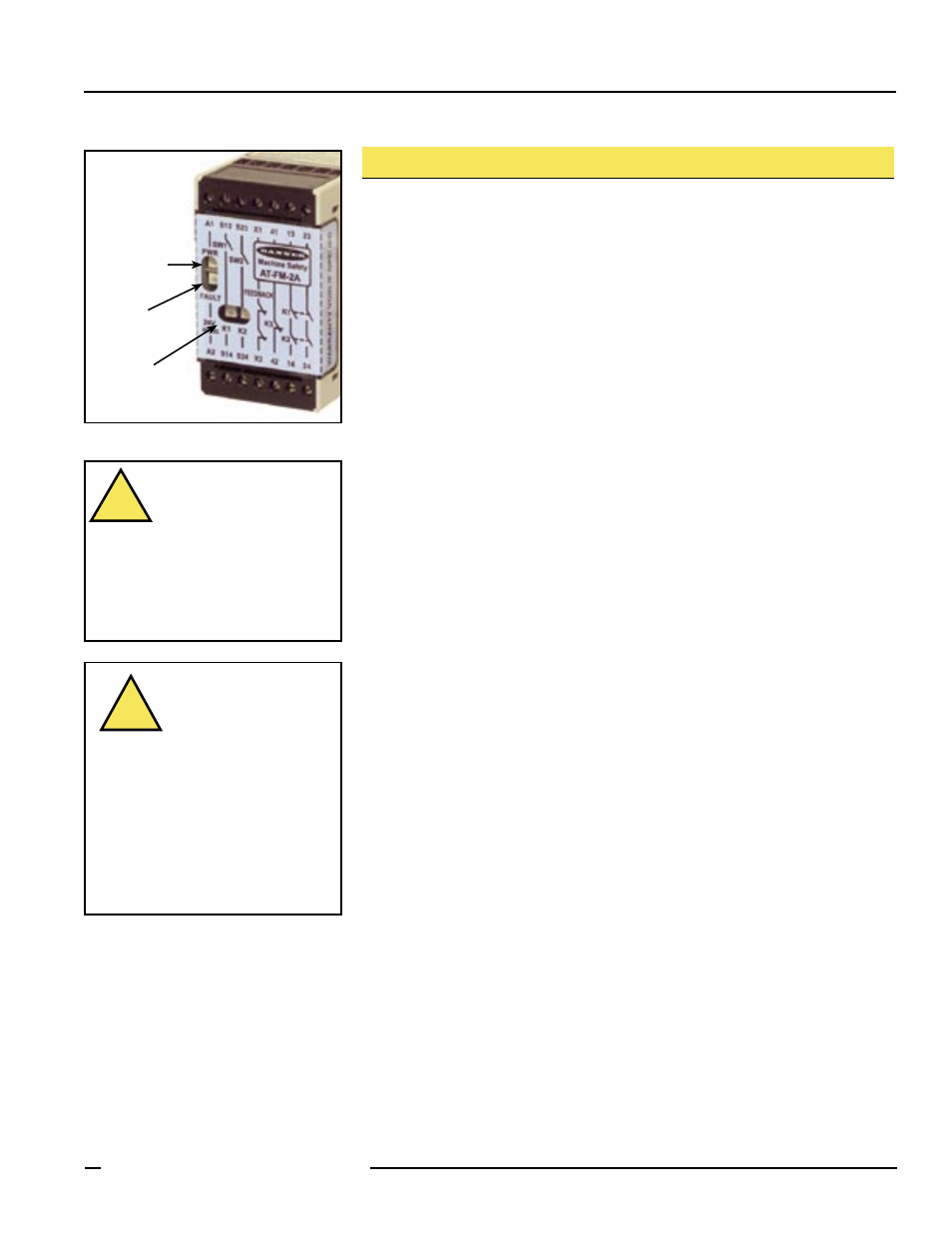

Figure 1. AT-..M-2A status indicators

CAUTION ...

Not an

Anti-Repeat Control Device

Anti-repeat control is not

a function of the AT-..M-2A Two-Hand

Control Safety Module. The user of this

device must provide a suitable means of

anti-repeat control for any single-stroke or

single-cycle machines.

!

WARNING ...

Avoid Hazardous

Installations

The user has the

responsibility to satisfy all local, state,

and national laws, rules codes, and

regulations relating to the use of safety

equipment in any application. It is extremely

important to be sure that all appropriate

agency requirements have been met

and that all installation and maintenance

instructions contained in the appropriate

manuals are followed.

!

Power

ON Indicator

Fault

Indicator

K1 and K2

Energized

Indicators