Duo-touch, Models at-..m-2a two-hand control modules – Banner DUO-TOUCH Two-Hand Control Modules User Manual

Page 5

P/N 47550 rev. E

5

DUO-TOUCH

®

– Models AT-..M-2A Two-Hand Control Modules

Banner Engineering Corp.

•

Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Installation of Hand Controls

Each actuating device requires a normally open (e.g., SPST) hard contact capable of

reliably conducting 20mA at 12V dc. For solid-state operation, model OTBVN6.. and

OTBVP6.. touch buttons must be used to ensure proper functionality.

Standards require that the actuating devices be mounted to pro tect them from

ac ci den tal or unintentional operation. Use shields, covers, rings, collars, dividers, or

similar protection to pre vent ac ci den tal switch actuation and to discourage use of

forearms or elbows. European standard ISO13851 includes a detailed discussion of

ap proach es to pro tec tion of hand controls.

The hand controls must be arranged far enough apart so that the operator cannot

operate both hand controls by the use of one arm (typically, not less than

550 mm/21.7" in a straight line, per ISO13851).

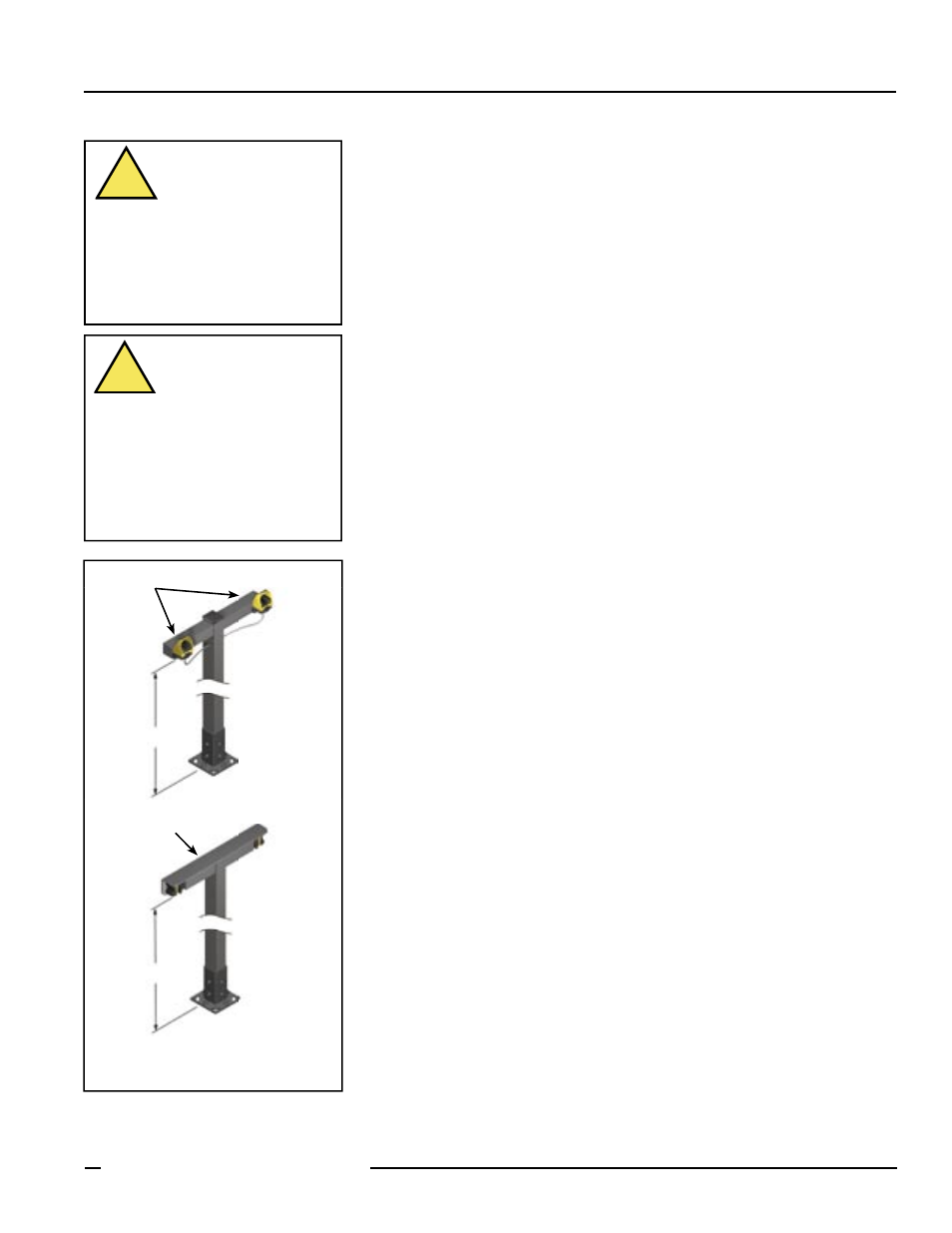

Figure 3 shows two examples for mounting Banner’s OTB Touch Buttons. When

mounted on top of the control bar, the protective field covers should be in place,

as shown. For added protection, mount the devices sideways under and behind a

protective hood, rather than on top of the bar, leaving the field covers off. This side

mount reduces the possibility of the operator easily positioning and leaving an object

in the path of the beam, intentionally bypassing the safeguard.

The hand controls must be arranged far enough apart so that the operator cannot

operate both hand controls using only one hand. Typically, this distance is not less

than 550 mm (21.7"), but using guards or an alternate mounting arrangement can

allow a shorter distance, per ISO13851 (EN574). This standard also recommends that

the hand control be arranged on a horizontal (or nearly horizontal) surface that is not

less than 1,100 mm (43.3") above the floor.

Employ ergonomic principles to avoid unnecessary fatigue in the use of the hand

controls. See ISO13851 (EN574) Two-Hand Control, ANSI B11.TR1–Ergonomic

Guidelines, and EN894–Safety of Machinery–Ergonomic Requirements–Control

Actuators for further information.

Requirements for Multiple-Operator Control

Standards have specified several conditions for situations where multiple operators

work together to control one machine:

• Each operator must actuate his/her own pair of actuating devices, with all pairs of

actuators active at one time, in order to initiate a machine cycle; the machine may

not be allowed to operate until this condition is true.

• The actuators all must be released between cycles.

• The actuation and de-actuation of all workstations requiring two-hand control must

be supervisable and must provide indication.

• The clutch/brake control system must be designed so that the clutch cannot be

actuated if all the operating workstations are bypassed.

It is the responsibility of the user to determine if this two-hand control system can be

interfaced to the machine in a manner to satisfy all existing requirements for multiple-

operator control.

CAUTION ...

Install

Hand Controls to Prevent

Accidental Actuation

Total protection for the two-hand control

system from “defeat” is not possible.

However, regulations require the user

to arrange and protect hand controls to

minimize possibility of defeat or accidental

actuation.

!

CAUTION ...

Hand

Controls

The environment in which

hand controls are installed must not

adversely affect the means of actuation.

Severe contamination or other

environmental influences may cause

slow response or false ON conditions of

mechanical or ergonomic buttons. This

may result in exposure to a hazard.

!

Figure 3. Protect activation devices in order

to prevent defeat or inadvertent

actuation

Side Mount

Top Plate Shield

Field Covers

Top Mount

1,100 mm (43.3")*

1,100 mm (43.3")*

* Minimum clearance,

per EN 574:1996 Chapter 8.5