Banner DUO-TOUCH SG Two-Hand Control Safety Modules User Manual

Page 6

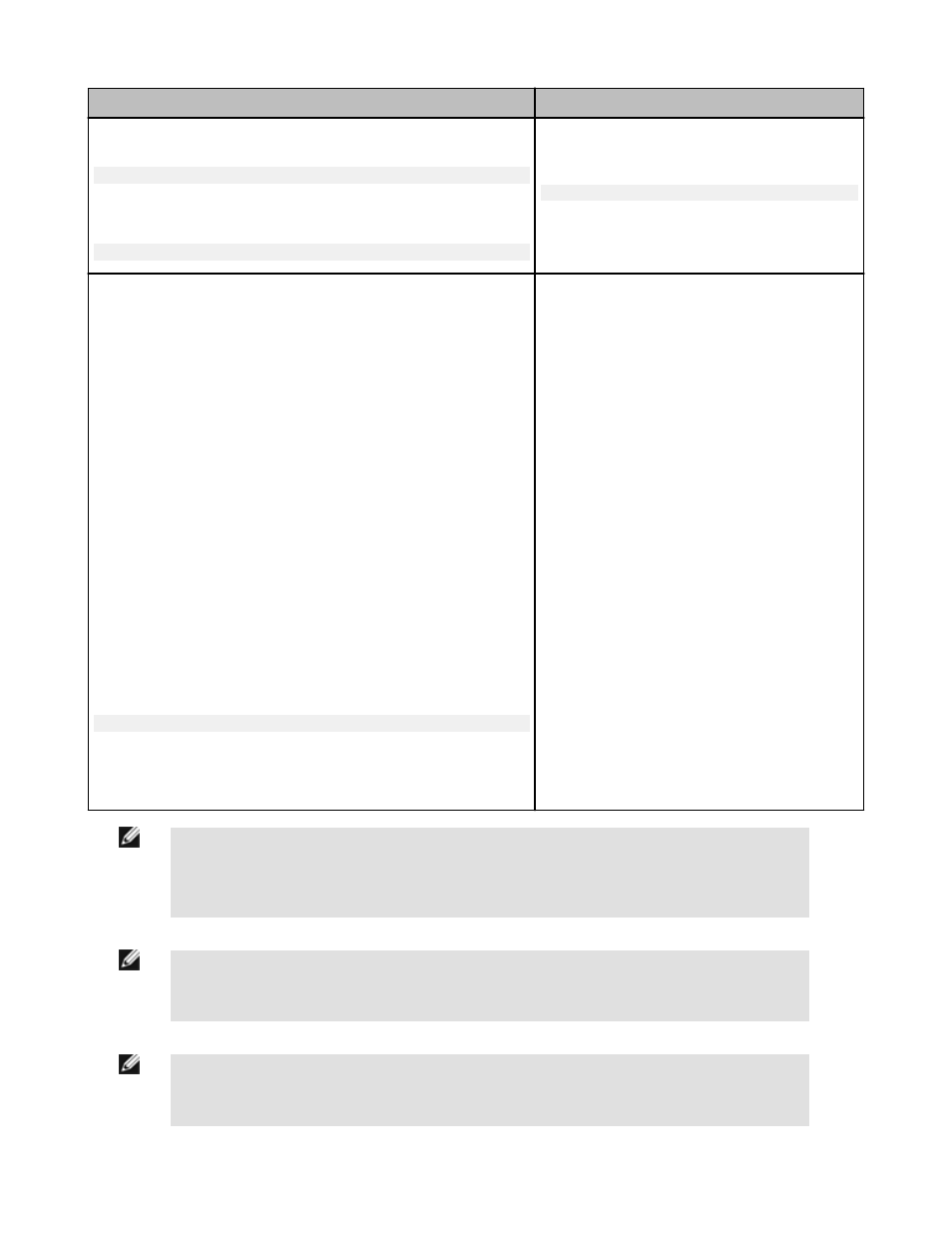

U.S. Applications

European Applications

Part-Revolution Clutch Machinery (the machine and its controls allow the

machine to stop motion during the hazardous portion of the machine cycle)

Ds = K x (Ts + Tr + Th)

S = (K x T) + C

For Full-Revolution Clutch Machinery (the machine and its controls are

designed to complete a full machine cycle, once activated)

Ds = K x (Tm + Tr + Th)

Ds = the separation (safety) distance in inches.

K = OSHA/ANSI and ISO 13855 hand speed constant of 1600mm/s (63 in.

per second).

Ts = the stop time (in seconds) of the machine, measured from the applica-

tion of the stop signal to the final ceasing of all motion, including stop times

of all relevant control elements, and measured at maximum machine veloci-

ty.

Tr = the response time of the Safety Controller as measured from the time a

stop is signalled by either hand control. Controller default response is 0.010

seconds, plus any additional closed-to-open debounce time. If the debounce

time is adjusted, the time in excess of 6 ms (default closed-to-open de-

bounce time) must be added to the stated response, see

GUID-C6745744-

F666-4551-8C89-7489F33E21E1

.

Th = the response time of the slowest hand control (from the time when a

hand disengages that control until the switch opens).

Tm = the maximum time (in seconds) the machine takes to cease all motion

after it has been tripped.

For full-revolution clutch presses with only one engaging point, Tm is equal

to the time necessary for one and one-half revolutions of the crankshaft.

For full-revolution clutch presses with more than one engaging point, Tm is

calculated as follows:

Tm = (1/2 + 1/N) x Tcy

N = number of clutch engaging points per revolution.

Tcy = time (in seconds) necessary to complete one revolution of the crank-

shaft.

S = the minimum safety distance in millimeters.

K = OSHA/ANSI and ISO 13855 hand speed constant

of 1600 mm/s.

T = the overall stop time of the machine, measured from

the actuation of the sensing function to the final ceasing

of all motion.

C = the added distance due to depth penetration factor:

250 mm, per ISO 13855. The ISO 13855 C factor can

be reduced to 0 if the risk of encroachment is elimina-

ted, but the safety distance must always be 100 mm or

greater.

NOTE: Ts is usually measured by a stop-time measuring device. If the specified machine stop time is used,

add at least 20% as a safety factor to account for brake system deterioration. If the stop-time of the two redun-

dant machine control elements is unequal, the slower of the two times must be used for calculating the sepa-

ration distance.

NOTE: Th is usually insignificant for purely mechanical switches. However, Th should be considered for safety

distance calculation when using electronic or electromechanical (powered) hand controls. For Banner Self-

checking Touch Buttons (STBs) the response time is 0.02 seconds.

NOTE: The hand-speed constant (K) has been determined by various studies, and although these studies

indicate speeds of 1600 mm/s, 2000 mm/s, to more than 2540 mm/s, they are not conclusive determinations.

Consider all factors, including the physical ability of the operator, when determining the value of K.

AT-FM-10K Two-Hand Control Module

6

www.bannerengineering.com - tel: 763-544-3164

P/N 64137 Rev. G