Led indicators, Module operation – Banner DUO-TOUCH SG Two-Hand Control Safety Modules User Manual

Page 3

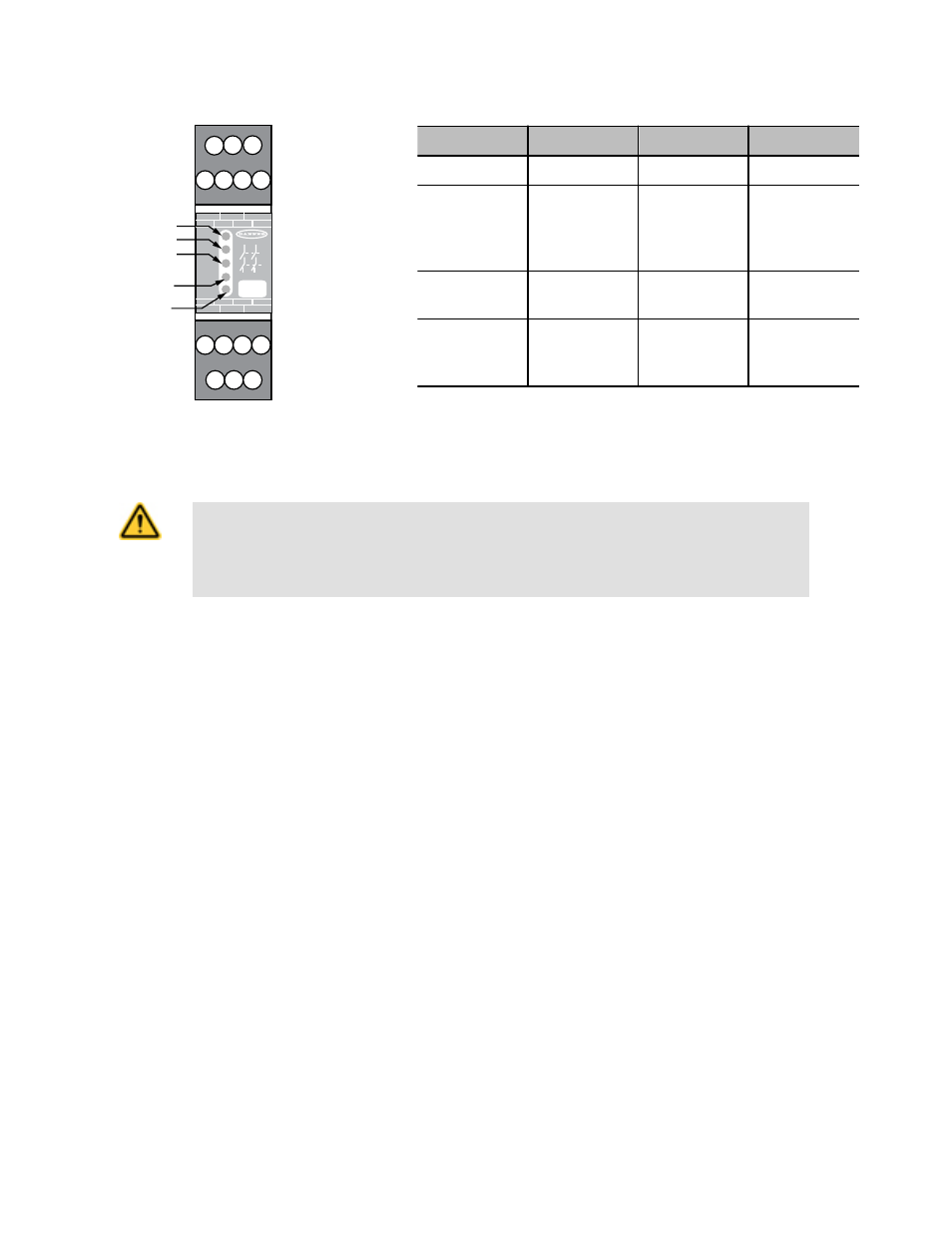

LED Indicators

S12

A1

S11

S13

S23

S21

S22

13

23

Y1

Y2

14

24

A2

K1

K2

14

24

13

23

Machine

Safety

AT-FM-10K

Power

Fault

In 1

In 2

Output

S12 S11 S13

A1 13 23 Y1

S23 S21 S22

Y2 14 24 A2

Power ON

(green)

Input 1 Status

(green)

Internal Fault (red)

Input 2 Status

(green)

Output Status

(green)

Figure 1. Status indicators and terminal locations

LED

ON

OFF

Flashing

Power ON

Power is applied No power

—

Fault

Simultaneity is

not met or

External wiring

fault

—

Internal fault

condition is de-

tected

Input 1 Status

Input 2 Status

Touch button is

activated

Button is not ac-

tivated

External wiring

fault is detected

Output Status

Both relays (K1

and K2) are

energized

—

Feedback error

Module Operation

CAUTION: Not an Anti-Repeat Control Device

Anti-repeat control is not a function of this Two-Hand Control Safety Module. The user of this device

must provide a suitable means of accomplishing anti-repeat control for any single-stroke or single-cycle

machine.

The Two-Hand Control Safety Module may be used as an initiation device for most powered machinery when machine cycling is control-

led by a machine operator.

Using a two-hand control system makes the operator a “hostage” while the hazard is present, thus limiting or preventing exposure to the

hazard. The two-hand control actuators must be located in a way that hazardous motion is completed or stopped before the operator can

release one or both of the buttons and reach the hazard (see Separation Distance).

The Safety Module’s safety inputs are used to monitor the actuation of the hand controls to comply with the functionality of Type III

requirements of IEC60204-1 and ISO 13851 (Type IIIa/Cat 4) and the requirements of ANSI NFPA79 and ANSI B11.19 for two-hand

control, which include:

• Concurrent (simultaneous) actuation by both hands within a 500 ms time frame

• Where this time limit is exceeded, a requirement that both hand controls must be released before operation is initiated

• Continuous actuation during hazardous condition

• Cessation of hazardous condition if either hand control was released

• Release and re-actuation of both hand controls to re-initiate the hazardous motion or condition (i.e., “anti-tie down”)

• The appropriate performance level of the safety-related function (e.g., Control Reliability, Category/Performance Level, or SIL) as

determined by a risk assessment or the applicable regulation and standards.

AT-FM-10K Two-Hand Control Module

P/N 64137 Rev. G

www.bannerengineering.com - tel: 763-544-3164

3