Mechanical installation, Part- and full-revolution clutched machinery, Heat dissipation considerations – Banner DUO-TOUCH SG Two-Hand Control Safety Modules User Manual

Page 4: Installation of hand controls

In addition, the Safety Module logic will not permit

the safety outputs to turn ON when power is initially

supplied and if the hand controls (actuators) are in

their Run state (e.g. both actuators tie-down). The

hand controls must change to their Stop state and

return to the Run state before the safety outputs

can turn ON.

The actuating devices must be protected from acci-

dental or unintended operation. This can be ac-

complished by their mounting position and/or

through the use of protective shields such as rings,

guards or shields; see Mechanical Installation.

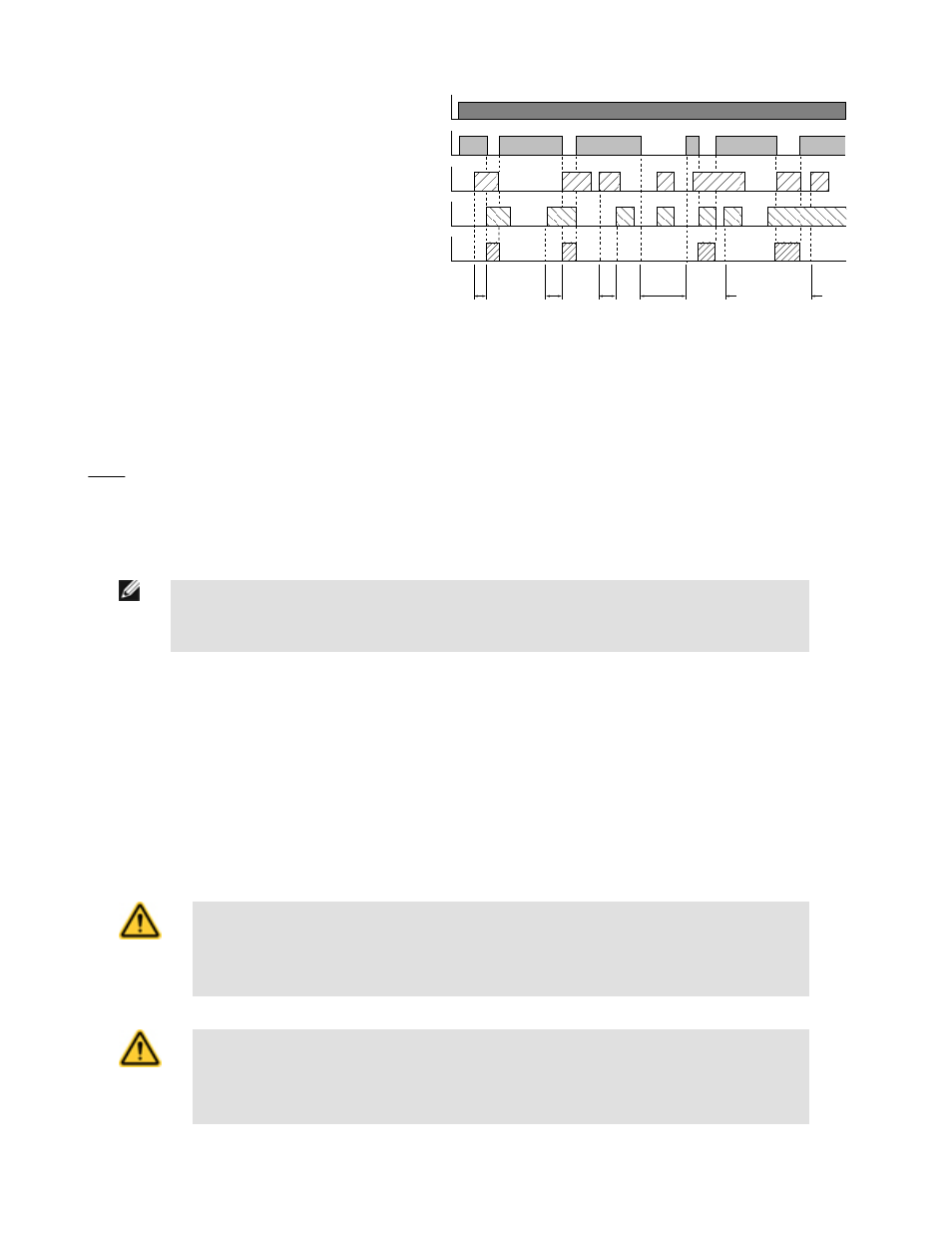

Power

< 0.5 s

< 0.5 s

Feedback Open

SW1 tied down

SW2 tied down

Feedback

Loop*

SW1

SW2

Output

> 0.5 s

Figure 2. Model AT-FM-10K timing logic

Part- and Full-Revolution Clutched Machinery

When used on part-revolution clutched machinery that can be stopped at any point during the cycle, the Safety Module can be used

for the following function types: “inch” (jog), “single-stroke,” or “continuous” (run).

When used on full-revolution clutched machinery (that can not be stopped until the end of the cycle), the Safety Module is used to

initiate the cycle and is known as a “two-hand trip device.”

In either situation, the hand controls must be safely located and protected from false operation (see Mechanical Installation and Separa-

tion Distance) and the Safety Module must be appropriately interfaced to the machine (see Electrical Installation).

When used in single-cycle or single-stroke mode, the machine control must provide an anti-repeat feature so that the operator must

release the two-hand control actuators after each machine cycle, before a new cycle can be initiated.

NOTE: Two-hand control and two-hand trip safeguarding protect

only the operator’s hands . Additional safe-

guarding (e.g., additional two-hand controls) may be required. Refer to the relevant standards for addition-

al requirements.

Mechanical Installation

Install the Safety Module inside an enclosure rated NEMA 3 (IEC IP54), or better. It is not designed for exposed wiring. The Module

mounts directly onto a standard 35 mm DIN rail.

Heat Dissipation Considerations

For reliable operation, ensure that the operating specifications are not exceeded. The enclosure must provide adequate heat dissipation,

so that the air closely surrounding the Module does not exceed the maximum operating temperature stated in the Specifications. Methods

to reduce heat build-up include venting, forced airflow (e.g., exhaust fans), adequate enclosure exterior surface area, and spacing be-

tween modules and other sources of heat.

Installation of Hand Controls

CAUTION: Hand Controls

The environment in which hand controls are installed must not adversely affect the means of ac-

tuation. Severe contamination or other environmental influences may cause slow response or false ON

conditions of mechanical or ergonomic buttons. This may result in exposure to a hazard.

CAUTION: Install Hand Controls to Prevent Accidental Actuation

Total protection for the two-hand control system from “defeat” is not possible. However, the user is re-

quired by OSHA regulations to arrange and protect hand controls to minimize possibility of defeat

or accidental actuation.

AT-FM-10K Two-Hand Control Module

4

www.bannerengineering.com - tel: 763-544-3164

P/N 64137 Rev. G