Superior design and construction – CommScope Trunk & Distribution Cable User Manual

Page 8

QR

®

- Superior Design and Construction

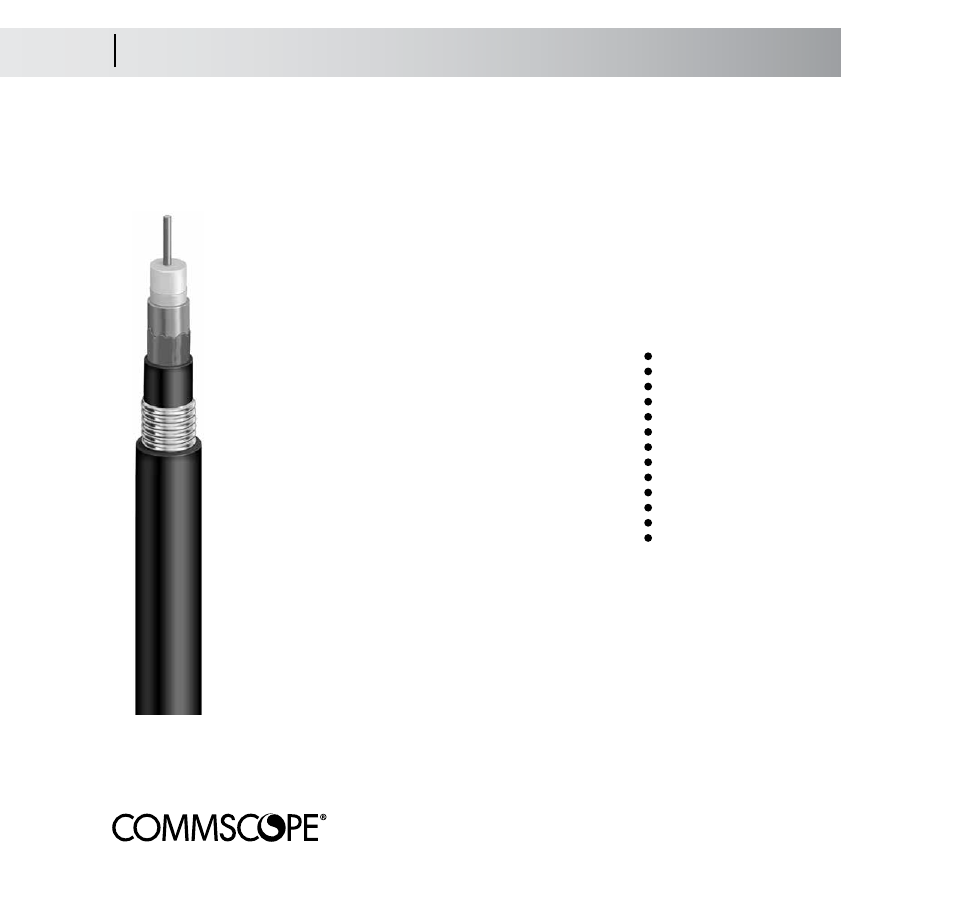

QR’s patented design combines several elements to achieve its unparalleled combination of superior

performance in a smaller, less expensive cable.

The QR center conductor is copper-clad aluminum for superior RF transmission and is

generally larger than the conductors found in competitive cable of similar outer diameter.

The QR dielectric is a closed-cell polyethylene that is compressed during the swaging pro-

cess. Compression allows the dielectric to actively press against the shield and help heal small

dents. The closed-cell nature of the dielectric permits an impressively high velocity of propaga-

tion of 88%.

The QR shield is formed through a unique, high efficiency

process where a precision tape is continuously roll-formed

around the core and is then welded by RF induction. This results

in a contaminant-free seam which is stronger than the

surrounding material. We verify seam integrity with a core and

cone test, where a cored sample is flared to a diameter well

beyond even the most extreme installed usage.

Migra-Heal

®

, CommScope’s special underjacket compound,

helps fill in jacket damage before moisture can seep in and cause corrosion.

The QR jacket is a tough medium-density polyethylene compound designed to resist the

effects of sun, moisture and temperature extremes.

Double jacketing, in which two independent jackets are separated by polypropylene tape, is

also available.

Steel armor is available for added protection.

Thin shield,

compressed

dielectric and

a larger center

conductor combine

to make QR the

best performing

coax available

anywhere

1.4 Introduction

QR Design Details and Advantages