Expansion loops – CommScope Trunk & Distribution Cable User Manual

Page 18

Expansion Loops

As temperature rises and falls, coaxial cable will expand/contract at almost twice the rate of strand. Expansion

loops allow the cable to move to allow for stress caused by thermal changes and strand creep. They are critical

to cable life. A typical loop will use no more than an extra 2 - 3 inches (5 - 8 cm) of cable.

Loops are formed using mechanical benders or bender boards. CommScope strongly recommends the

use of mechanical benders for consistently-formed loops.

When to place expansion loops

Loops are formed prior to lashing in the back-pull method and during lashing in the

drive-off method. In either case, it is recommended that you keep the bender in place

as the cable is being lashed. Remove the bender only after the cable has been lashed

to the strand.

Where to place expansion loops

Form one expansion loop at each pole, on the input/output of every active device and

at every tap. Form two loops at a pole where the span length exceeds 150 feet

(45 meters), on street/RR crossings and in spans with little to no midspan sag.

If you are running multiple cables, do not bind them together in the same loop.

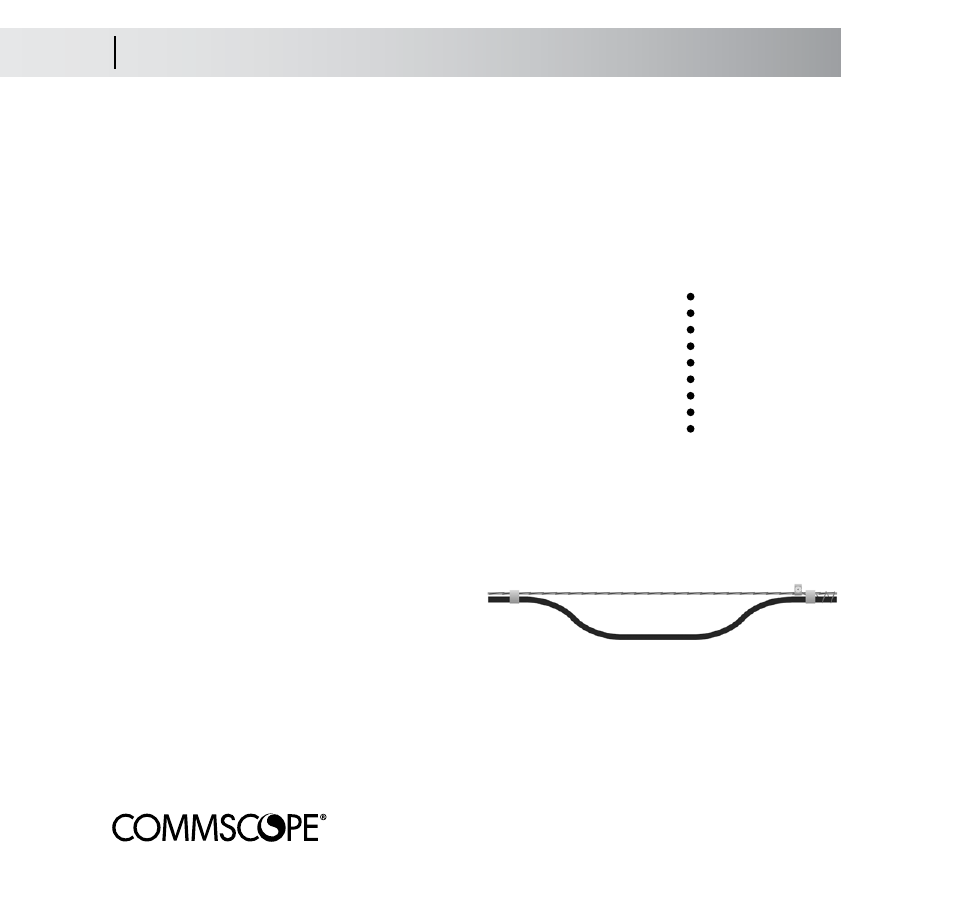

An expansion loop is supported on the strand by a

strap fitted with a spacer that separates the cable from

the strand. The strap should be no more than

hand-tightened.

The cable must be permitted to move within

the loop or the cable may buckle and fail.

Place the bug nut 4” from the end of the loop and place the spacer and strap on the span side of the loop

behind the bug nut. (See diagram.) Note: the end of the loop is at the end of the loop forming tool.

QR expansion

loops will last

2 - 3 times

longer than

those of

conventional

coaxial cable

Pole Side

Span Side

3.4

Aerial Installation

Espansion Loops