Bending radii – CommScope Trunk & Distribution Cable User Manual

Page 17

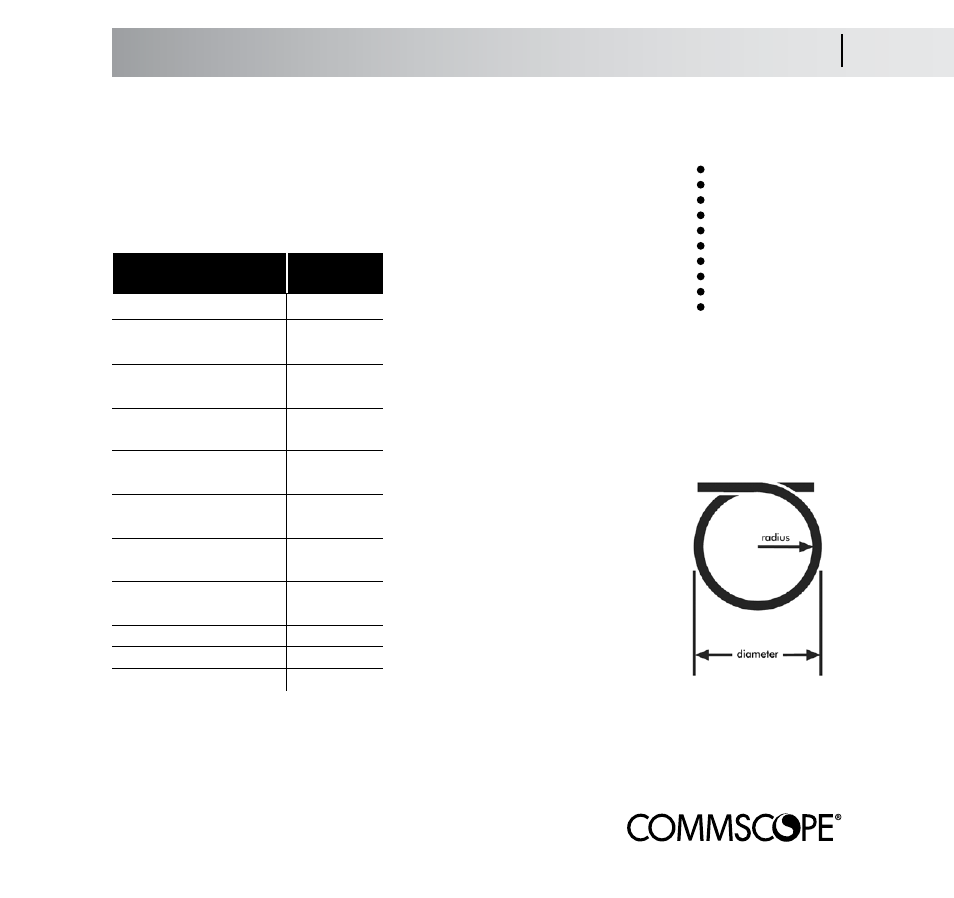

Bending Radii

Cables are often routed around corners during cable placement and pulling tension

must be increased to apply adequate force to the cable to bend the cable around the

corner. Tension is directly related to the flexibility of cable - and flexibility is QR’s greatest

strength.

CommScope’s specified minimum

bending radius is the static (unloaded)

bending radius of the cable. This is the

minimum radius to which the cable can

be bent without electrically or mechanically degrading the

performance of the cable. Bending the cable in this manner is

usually only done during splicing or final forming. This is also the

radius allowed for storage purposes.

Always review the specifications for the appropriate

bend radii. If you do not exceed the minimum bend

radius nor exceed the maximum

pulling tension, you should have a

successful installation.

The bending radii of cables during the

construction process are controlled by

construction techniques and equipment.

Corner blocks and set-up chutes have

large radii and low friction surfaces that

minimally contribute to the overall

increase in pulling tension.

QR cable’s

shield

construction

permits the

tightest bend

radius in the

industry

Minimum

Cable

Bending Radii

in/cm

QR 320

3 (7.6)

QR 540

4 (10.2)

QR 540 armored

6.5 (16.5)

QR 715

5 (12.7)

QR 715 armored

7.5 (19.1)

QR 860

7 (17.8)

QR 860 armored

9.5 (24.1)

P3 500 standard (jacketed)

6.0 (15.2)

P3 500 bonded (jacketed)

3.5 (8.9)

P3 625 standard (jacketed)

7.0 (17.8)

P3 625 bonded (jacketed)

4.5 (11.4)

P3 750 standard (jacketed)

8.0 (20.3)

P3 750 bonded (jacketed)

6.0 (15.2)

P3 875 standard (jacketed)

9.0 (22.9)

P3 875 bonded (jacketed)

7.0 (17.8)

MO500

6.0 (15.2)

MO650

7.0 (17.8)

MO750

8 (20.3)

Aerial Installation

3.3

Bending Radii