Advanced coring technology – CommScope Trunk & Distribution Cable User Manual

Page 5

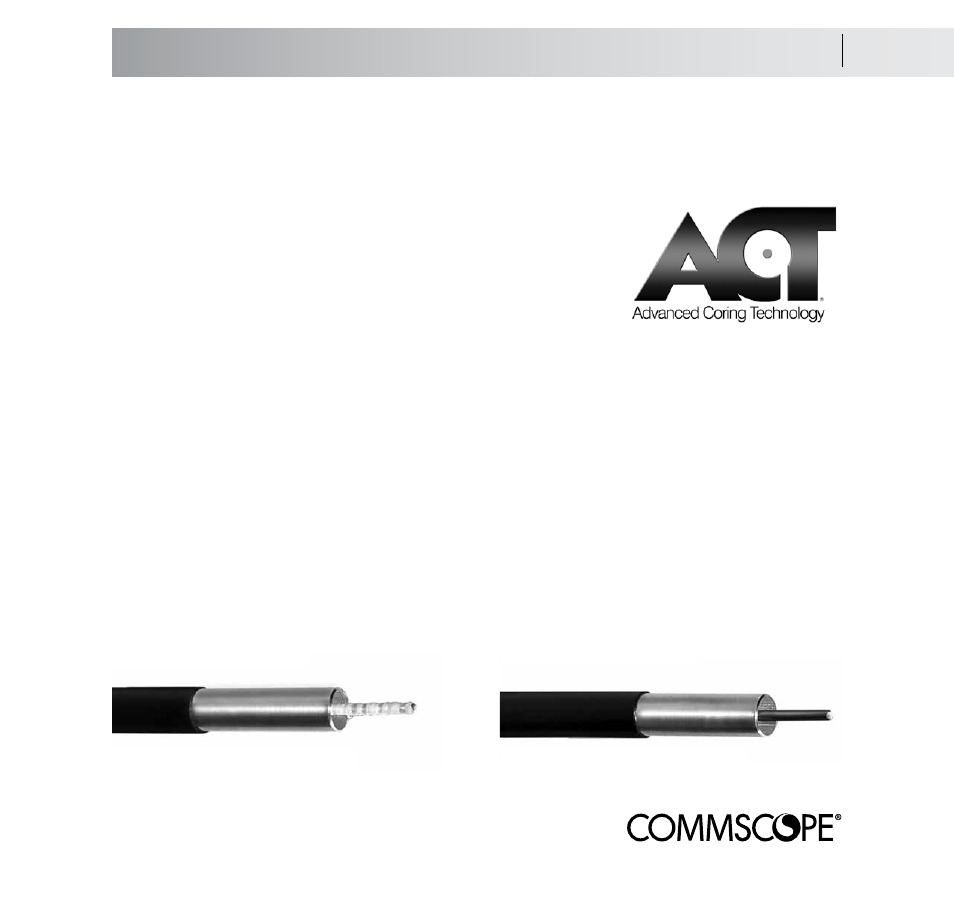

Advanced Coring Technology

®

• Enhanced Mechanical Performance

• Meets/Exceeds ANSI/SCTE, EN50117, IEC and Cenelec

• Fully Backward Compatible

• Identical in Electrical Performance

• Patent Pending

Another CommScope Innovation...Setting a New Standard in Cable Technology!

Traditional coaxial trunk and distribution cables require considerable attention to the preparation of the cable end

for proper connectorization. Critical to that end preparation is the proper removal of dielectric and bonding com-

pound from the conductors.

The normal process for this requires the craftsman to first core the cable and then clean the center conductor in a

second step. CommScope’s new P3

®

with ACT

®

and QR

®

with ACT

®

cables virtually eliminate the center

conductor cleaning step by enabling a clean coring process in which the center conductor is cleaned of dielectric

and bonding compound during the coring process.

These cables meet and exceed all ANSI/SCTE, EN50117, IEC and Cenelec testing methods for trunk, feeder, and

distribution cables.

Below is an example of a

traditional P3

®

Cable:

Residual dielectric and bonding com-

pound on conductor after coring

Conductor clean of dielectric and

bonding compounds after coring

Below is an example of

P3

®

with ACT

®

:

Introduction 1.1

ACT

®

- Advanced Coring Technology