Pulling tension – CommScope Trunk & Distribution Cable User Manual

Page 43

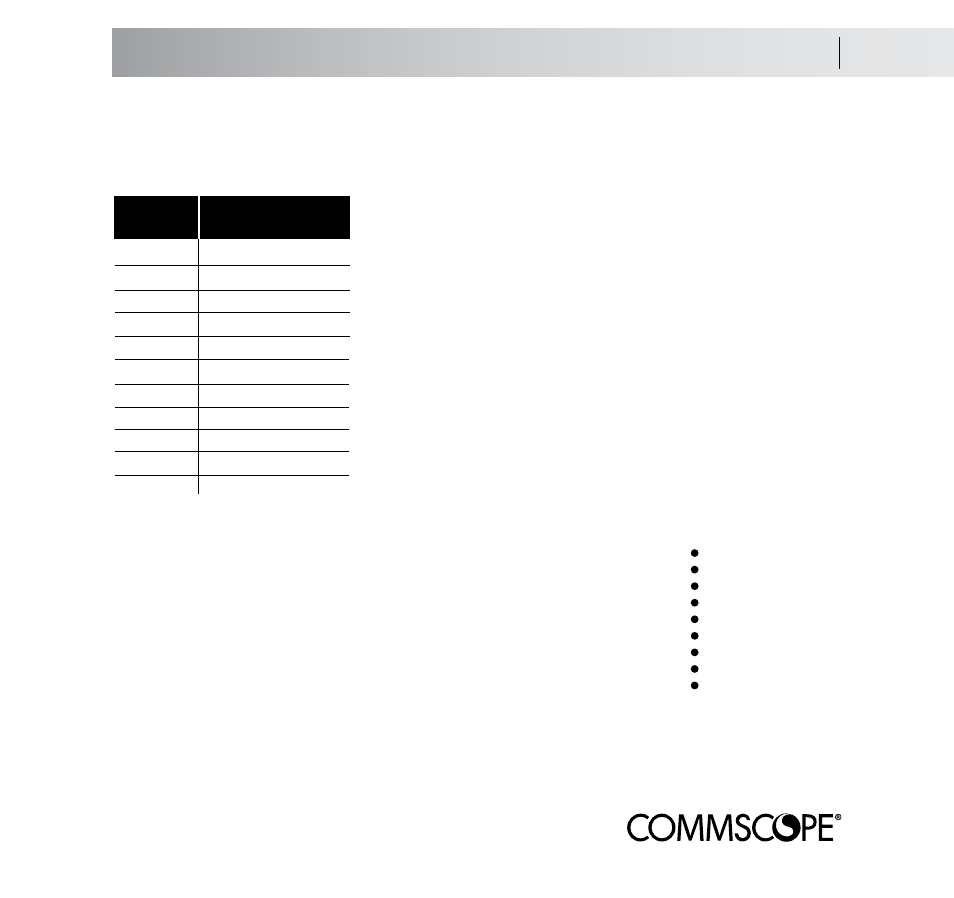

Pulling Tension

Pulling tension for CommScope cable types are shown in this chart.

NEVER EXCEED THE MAXIMUM PULLING TENSION.

Excessive forces applied to the cable will cause the cable to permanently

elongate. Good construction techniques and proper tension monitoring

equipment are essential. The highly flexible nature of QR cable makes it

very difficult to exceed the maximum pulling tension.

Tail loading is the tension in the cable caused by the mass of the cable

on the reel and reel brakes. Tail loading is controlled by two methods.

It can be minimized by using minimal braking during the pay-off of the

cable from the reel - at times, no braking is preferred. Tail loading can

also be minimized by rotating the reel in the direction of pay-off.

Break-away swivels should be placed on each cable to ensure that the maximum

allowable tension for that specific cable type is not exceeded. The swivel is placed

between the cable puller and pulling grip. A break-away swivel is required for each

cable being pulled.

Dynamometers are used to measure the dynamic tension in the cable. These

devices allow continuous review of the tension and accordingly a realization can be

made of any sudden increase in pulling tension.

Cable

Max. Pulling Tension

lbs / kgf

QR 320

120 (54.5)

QR 540

220 (100)

QR 715

340 (154)

QR 860

450 (204)

P3 500

300 (136)

P3 625

475 (216)

P3 750

675 (306)

P3 875

875 (397)

MO500

270 (123)

MO650

360 (164)

MO750

500 (227)

QR’s flexible

construction

means

longer runs

and more

45°/90° bends

are possible

Underground Installation

5.2

Pulling Tension