Getting a clean core, Summary – CommScope Trunk & Distribution Cable User Manual

Page 55

Getting a Clean Core

To take advantage of an ACT cable’s unique clean coring capabilities there are a couple of simple “Best Practice”

procedures that the splicer must understand and put into practice.

• Drill Coring – To enable the tool to optimize its shear

ing force while coring:

- Keep the RPM’s below 450 (low speed)

- Apply slightly more forward pressure than usual for about the first ¼ inch of the core, then resume normal

forward pressure

- Some will find it easier to “trigger” the drill in short 1-2 second bursts for about the first ¼ inch of the core,

replicating a hand core action, rather than controlling a constant low drill speed

• Hand Coring – While not the preferred method of most splicers, it does provide a consistent clean core

operation without any special needs.

Most standard tools are able to provide the proper shearing force necessary to facilitate a clean core. However, a

splicer may find that they have a tool that does not provide a consistent clean core. In the event that this occurs,

ACT cables enable the splicer to easily remove the remaining bonding compound and dielectric with a traditional

center conductor cleaning tool. This removal is accomplished with greater ease than was ever possible with

traditional cables.

Summary

The bond strength in cable is critical to the mechanical performance

of the cable. However, bonding affects more than just the cable’s

mechanical characteristics, it also impacts the facilitation of cable

preparation and connectorization. Finding the balance of bond

strength and craft friendliness is accomplished by the development

of an advanced technology bonding agent and coupling it with

CommScope’s consistent manufacturing process controls. This

achievement enables the cable to mechanically behave the way it

needs to and makes the preparation easier.

With some simple “best practice” procedures, a splicer will find it

easy to consistently achieve a one step clean core.

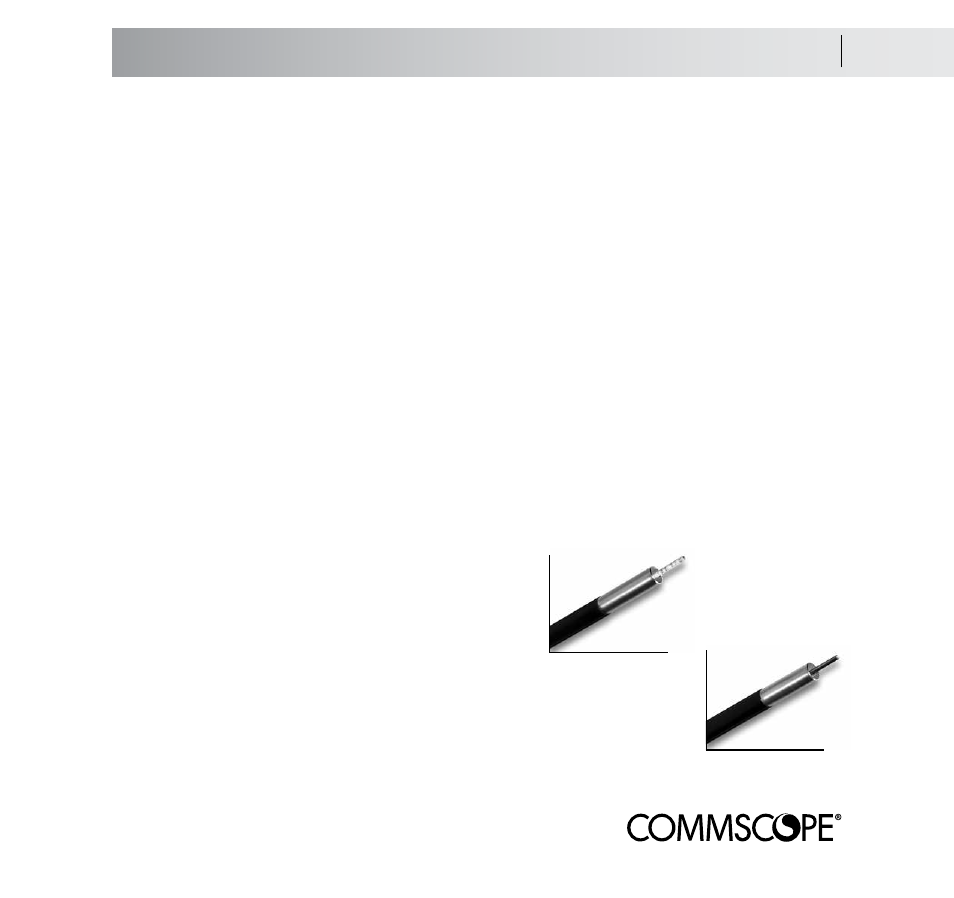

Below is an example of

traditional P3

®

cable

Residual dielectric and

bonding compound on

conductor after coring

Below is an example of

P3

®

cable with ACT

®

Conductor clean of dielectric

and bonding compounds

after coring

Connectorization 6.6

ACT

®

- Advanced Coring Technology