Connecting the startup switch, Connecting the transducer – Rockwell Automation 1440-SPD02-01RB XM-220 Dual Speed Module User Manual

Page 37

Publication GMSI10-UM004B-EN-P - May 2010

Installing the XM-220 Dual Speed Module 29

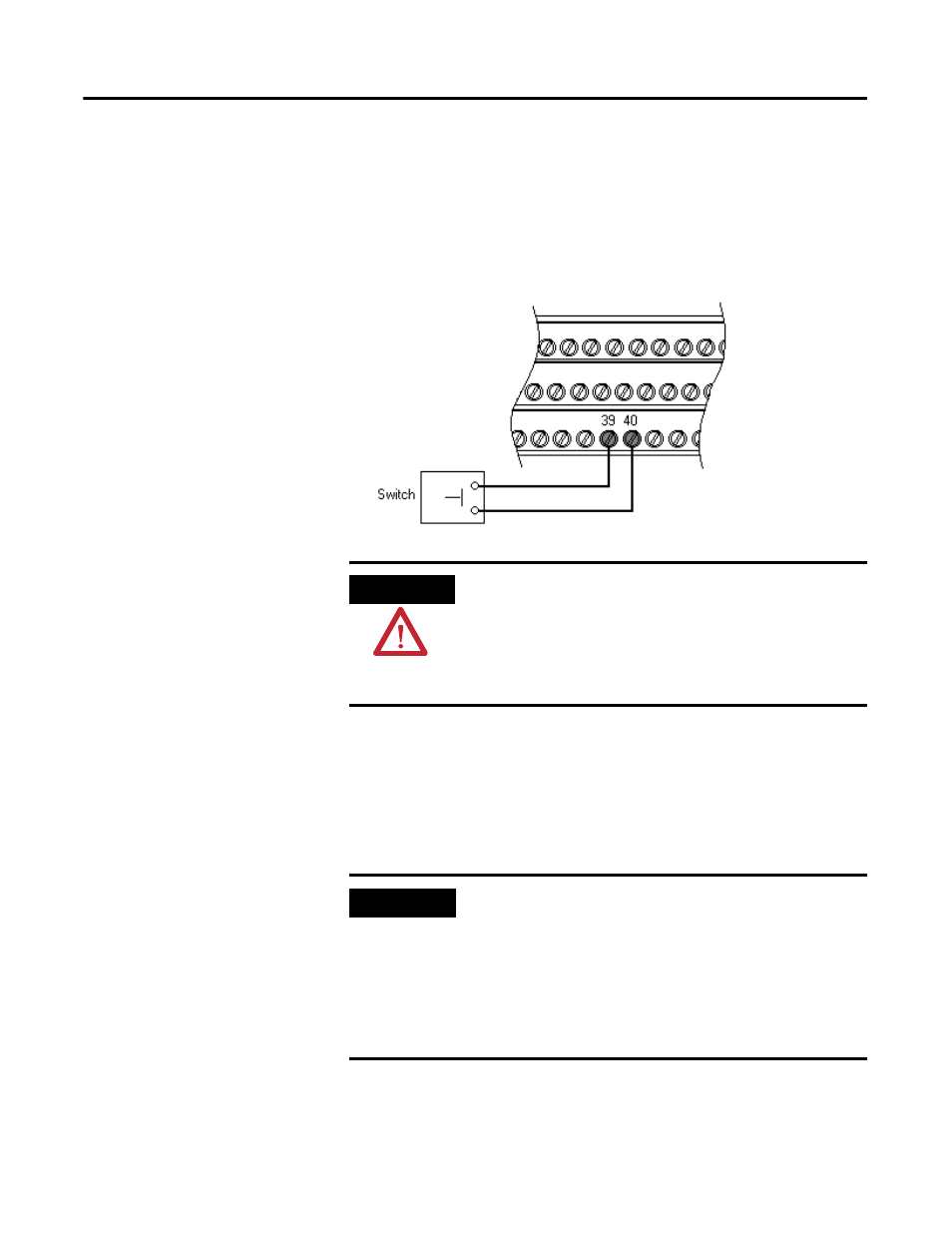

Connecting the Startup Switch

You can configure the module to detect a locked rotor condition or inhibit the

tachometer fault alarm status during the start-up period. Wire the Startup

switch to the terminal base unit as shown in Figure 2.18.

Figure 2.18 Startup Switch Connection

Connecting the Transducer

The XM-220 can accept input signals from any Allen-Bradley non-contact

eddy current probe, magnetic pickups, or TTL output devices.

ATTENTION

The Switch Input circuits are functionally isolated from

other circuits. It is recommended that the Switch RTN

signal be grounded at a signal point. Connect the Switch

RTN signal to the XM terminal base (Chassis terminal) or

directly to the DIN rail, or ground the signal at the switch

or other equipment that is wired to the switch.

IMPORTANT

Active magnetic speed sensors or eddy current probes are

often used on machines where rotational speeds below 250

rpm must be reliably sensed, for example reverse rotation

and zero speed applications. Passive magnetic speed

sensors do not typically generate a suitable signal at slow

shaft rotational speeds. To sense shaft rotation speeds

down to 1 rpm, active magnetic speed sensors or eddy

current probes are required.