Safe torque-off feature, Safe torque-off feature bypass – Rockwell Automation 2099-BMxx-S Kinetix Safe Torque-off Feature Safety Reference Manual User Manual

Page 23

Rockwell Automation Publication GMC-RM002F-EN-P - June 2013

23

Wiring Your Kinetix Safe Torque-off Drive Chapter 3

Safe Torque-off Feature

The safe torque-off circuit, when used with suitable safety components, provides

protection according to EN ISO 13849-1 (PLe), Cat3 or according to EN 62061

(SIL3). The safe torque-off option is just one safety control system. All

components in the system must be chosen and applied correctly to achieve the

desired level of operator safeguarding.

The safe torque-off circuit is designed to safely turn off all of the output-power

transistors. You can use the safe torque-off circuit in combination with other

safety devices to achieve the stop and protection-against-restart as specified in

IEC 60204-1.

The Kinetix 6000 and Kinetix 7000 drives do not operate without a safety circuit

or safety bypass wiring. For applications that do not require the safe torque-off

feature you must install jumper wires to bypass the safe torque-off circuitry.

Safe Torque-off Feature Bypass

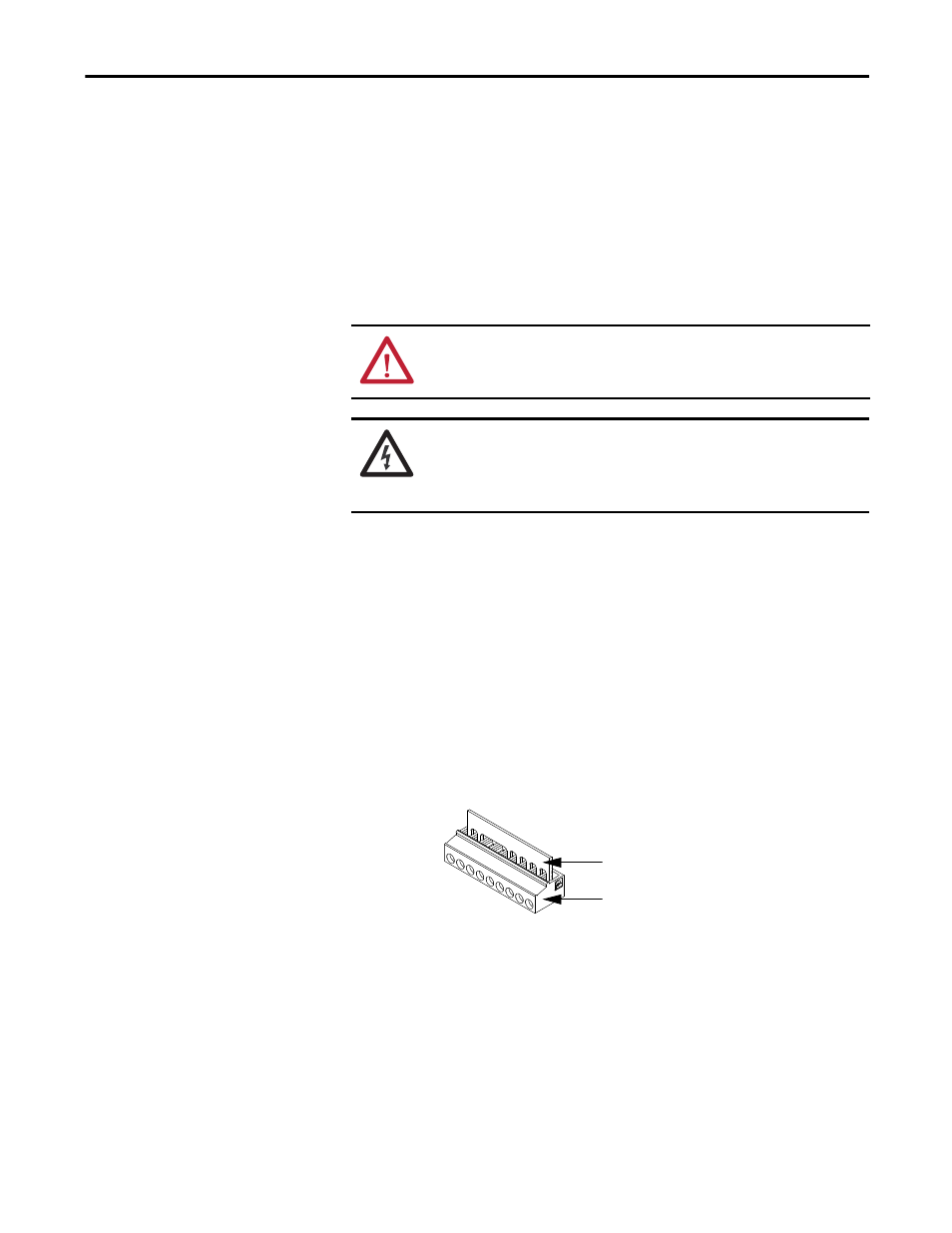

Each Kinetix 6000 and Kinetix 7000 safe torque-off drive ships with the (9-pin)

wiring plug header and motion-allowed jumper. With this wiring header/jumper

combination installed in the safe torque-off (STO) connector (default

configuration), the safe torque-off feature is not used.

Figure 12 - Wiring Plug Header with Motion-allowed Jumper

ATTENTION: This option may be suitable for performing mechanical work on

the drive system or affected area of a machine only. It does not provide

electrical safety.

SHOCK HAZARD: In Safe Torque-off mode, hazardous voltages may still be

present at the drive. To avoid an electric shock hazard, disconnect power to the

system and verify that the voltage is zero before performing any work on the

drive.

1

1 2 3 4 5 6 7 8 9

Motion-allowed Jumper

Wiring Plug Header