7 trqmem routine – Rockwell Automation 9329 Drive Application Software Tension Control Gen. Units User Manual

Page 29

FM – Tension Control

Drive Application Software – page 29 of 52

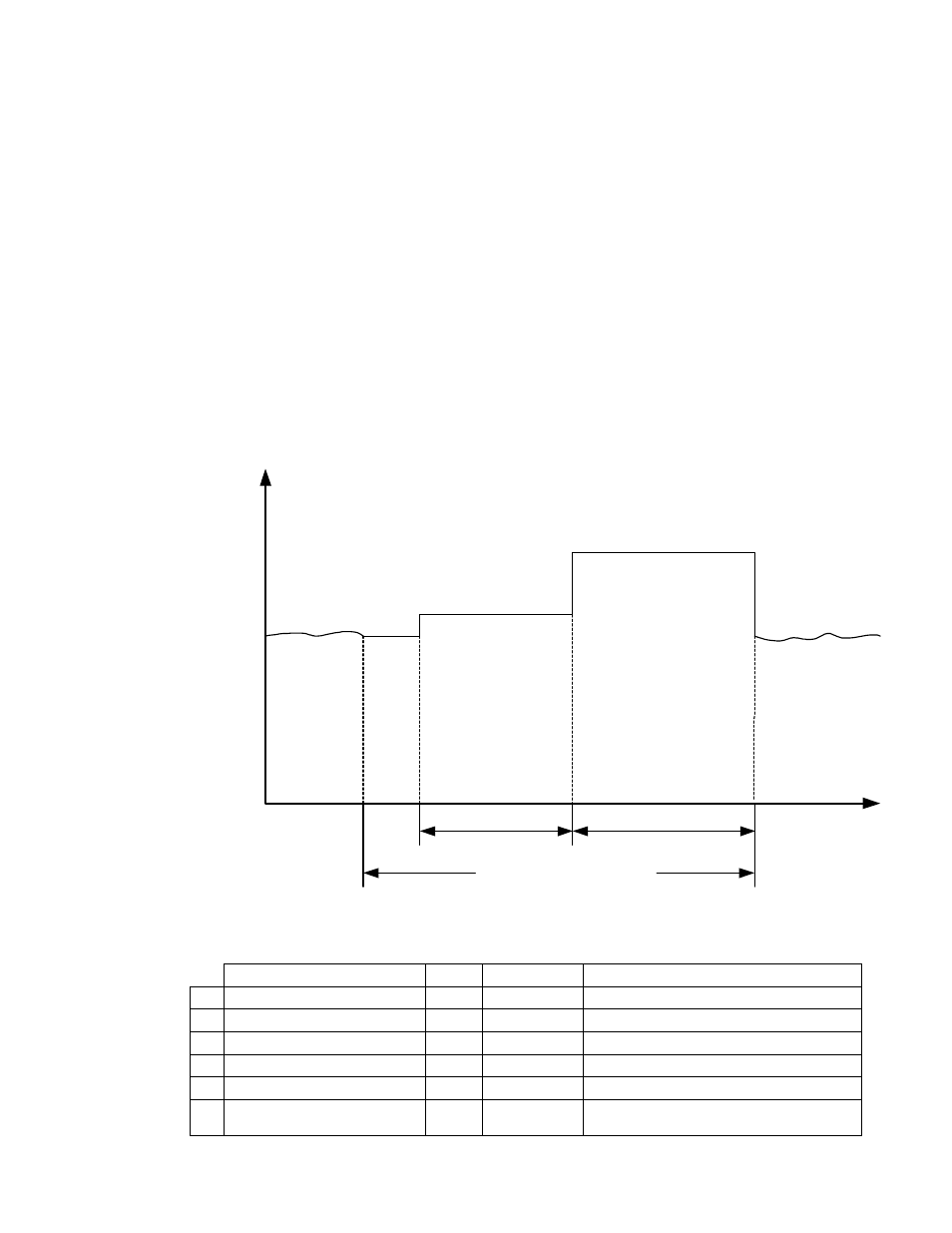

4.7 TrqMem routine

The torque memory subroutine is used to hold the drive’s torque reference at a constant

value when a roll change is performed on a Center Winder with automatic roll change

support. The base torque memory value is the torque feedback prior to enabling torque

memory. The Torque Memory Routine has two Boost commands. The first is a

TrqMemBoostEnbl and the other is a TrqMemKnifeBoostEnbl. Both of these boosts have

individual settings. Both settings are a percentage multiplier to the base memorized torque

from the drive.

For example, the drive’s torque feedback was varying between 49 to 51 percent. When the

torque memory is enabled the Torque Feedback was 50 percent. The Torque Memory base

value is now set to 50 percent. The TrqMemBoostRf_Pct is set for 10% and the

TrqMemKnifeBoostRf_Pct is set for 50%. When the TrqMemBoostEnbl is set, the Torque

Memory Reference is set to 55% (1.10 * 50% = 55%). When the TqMemKnifeBoostEnbl is

set, the Torque Memory Reference is set to 75% (1.50 * 50% = 75%). Once Torque memory

is disabled the Torque Memory Reference is set equal to the Torque Feedback of the drive.

Input Parameters

Name

Type

Range

Description

1 TrqFb_PU

REAL

NA

Torque Feedback Per Unit

2 DrvTrqRfJLoss_PU

REAL

NA

Torque Reference for inertia & Losses

3 TrqMemBoostEnbl

BOOL

0 to 1

Torque Memory Boost Enable

4 TrqMemBoostRf_Pct

REAL

10 to 300

Torque Memory Boost Reference

5 TrqMemKnifeBoostEnbl

BOOL

0 to 1

Torque Memory Knife Boost Enable

6 TrqMemKnifeBoostRf_Pct

REAL

10 to 300

Torque Memory Knife Boost

Reference

Torque

Time

TrqMemBoostEnbl

TrqMemKnifeBoostEnbl

Torque Memory Enable