3 main routine, 4 logic routine – Rockwell Automation 9329 Drive Application Software Tension Control Gen. Units User Manual

Page 16

FM – Tension Control

Drive Application Software – page 16 of 52

4.3 Main routine

The Main routine consists of four rungs of ladder logic programming. A rung description

briefly describes the Input and Return (output) parameters of the JSR instructions for each

routine called. Temporary tags have been entered for each input parameter and each return

parameter. The tag names entered in the JSR’s are not declared. The user must replace

these tag names with existing project tags or create new tags. The routine will show an error

until all input and return parameters are satisfied. The input parameters may also be entered

as actual values. If an input parameter is set to a value and not a tag, the value cannot be

edited in run mode. Values entered directly in the JSR should be constants that do not

change during machine operation. Specific formatting is required for values entered directly

in the JSR.

NOTE: For Application Module users, the tags in the JSR’s are predefined and configured for

operation. No additional integration is necessary.

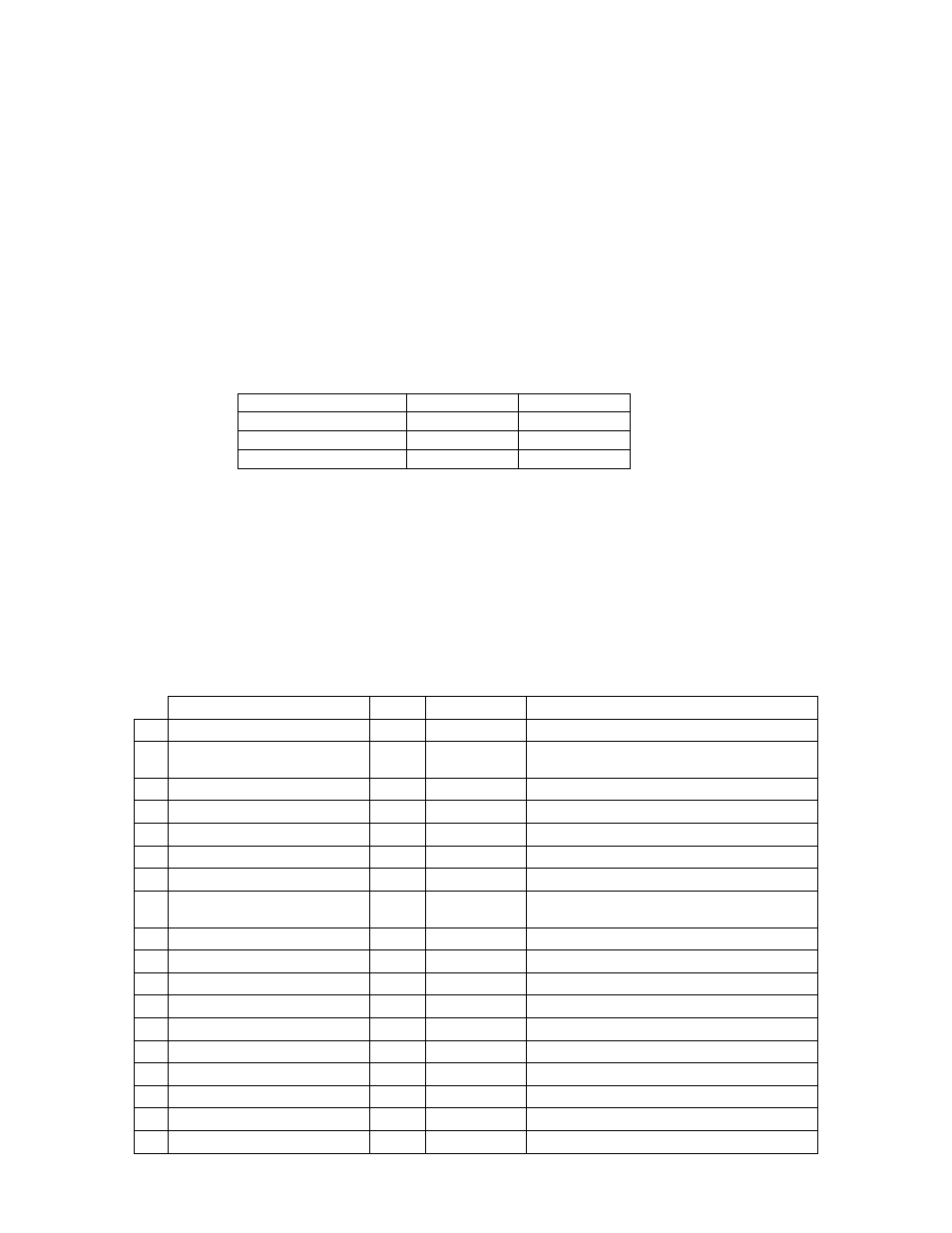

Data Type

Format

Example

B = Boolean

x

0 or 1

I = Integer

x

123

R = Real (Float)

x.x

3.4 / 13.0

If any signal scaling is required to interface the FM into the user application, the user may use

the main routine for this programming. Note; Scaling for inputs to the routines should be

done before the JSR and any scaling applied to the return values from the routines should

be done after the JSR.

4.4 Logic Routine

The Logic Routine is used to configure the Tension Control Function Module. In this routine

the selected tension mode is tested, constants for speed and torque scaling are generated,

and sections of code are enabled or disable depending on the tension mode selected.

Input Parameters

Name

Type

Range

Description

1 CtrlEnbl

BOOL

0 to 1

Enables the Tension Control Module

2 Running

BOOL

0 to 1

Releases the tension regulator when the

machine is running

3 TenCtrl

BOOL

0 to 1

Select Tension Control

4 TrqCtrl

BOOL

0 to 1

Select Torque Control

5 DanCtrl

BOOL

0 to 1

Select Dancer Control

6 TrqTrim

BOOL

0 to 1

Regulator adjust Trq Reference

7 SpdTrim

BOOL

0 to 1

Regulator adjust Speed Reference

8 TenZoneDwStream

BOOL

0 to 1

Location of the Tension Zone with

respect to the controlling section

9 ReverseRotation

BOOL

0 to 1

selects the sign of the Torque signal

10 TrimHoldHigh

BOOL

0 to 1

Trim Regulator Hold High

11 TrimHoldLow

BOOL

0 to 1

Trim Regulator Hold Low

12 TenRfStall

BOOL

0 to 1

Stall Tension Reference Selected

13 TrqFbJLoss

BOOL

0 to 1

Torque Fdbk includes Inertia & Friction

14 TrqMemEnbl

BOOL

0 to 1

Torque Memory Enable

15 TrqFolwCtrl

BOOL

0 to 1

Torque Follower Control

16 TenMax_EU

REAL

NA

Tension Maximum [Engineering Units]

17 RadiusCalc_EU

REAL

NA

Calculated Radius

18 GearRatio

REAL

NA

Gear Ratio [Motor Speed/Roll Speed]