5 regulator routine – Rockwell Automation 9329 Drive Application Software Tension Control Gen. Units User Manual

Page 21

FM – Tension Control

Drive Application Software – page 21 of 52

4.5 Regulator routine

The regulator routine is responsible for closing the tension, position or torque loop. This

routine is also responsible for switching between stall and run reference. When enabled, the

regulator will ramp the reference set point from the feedback value to the set point.

This routine accepts the feedback directly from the analog input module. The routine will

then scale the feedback from minimum tension reference to a maximum tension reference.

This routine also generates a feed forward torque reference based on the tension set point,

roll radius, gear ratio and motor rated torque.

The closed loop system consists of a lead-lag filter and a PI regulator. This has the ability to

close all three types of tension regulation loops (tension, position or torque). When the

regulator is configured for tension, the feedback is actual tension from a load cell. When the

regulator is configured for position, the feedback is the actual position feedback of a dancer.

There is a signal generated in the routine that may be optionally used to apply loading

pressure to the dancer. When the regulator is configured for torque, the feedback is the

torque feedback from the drive.

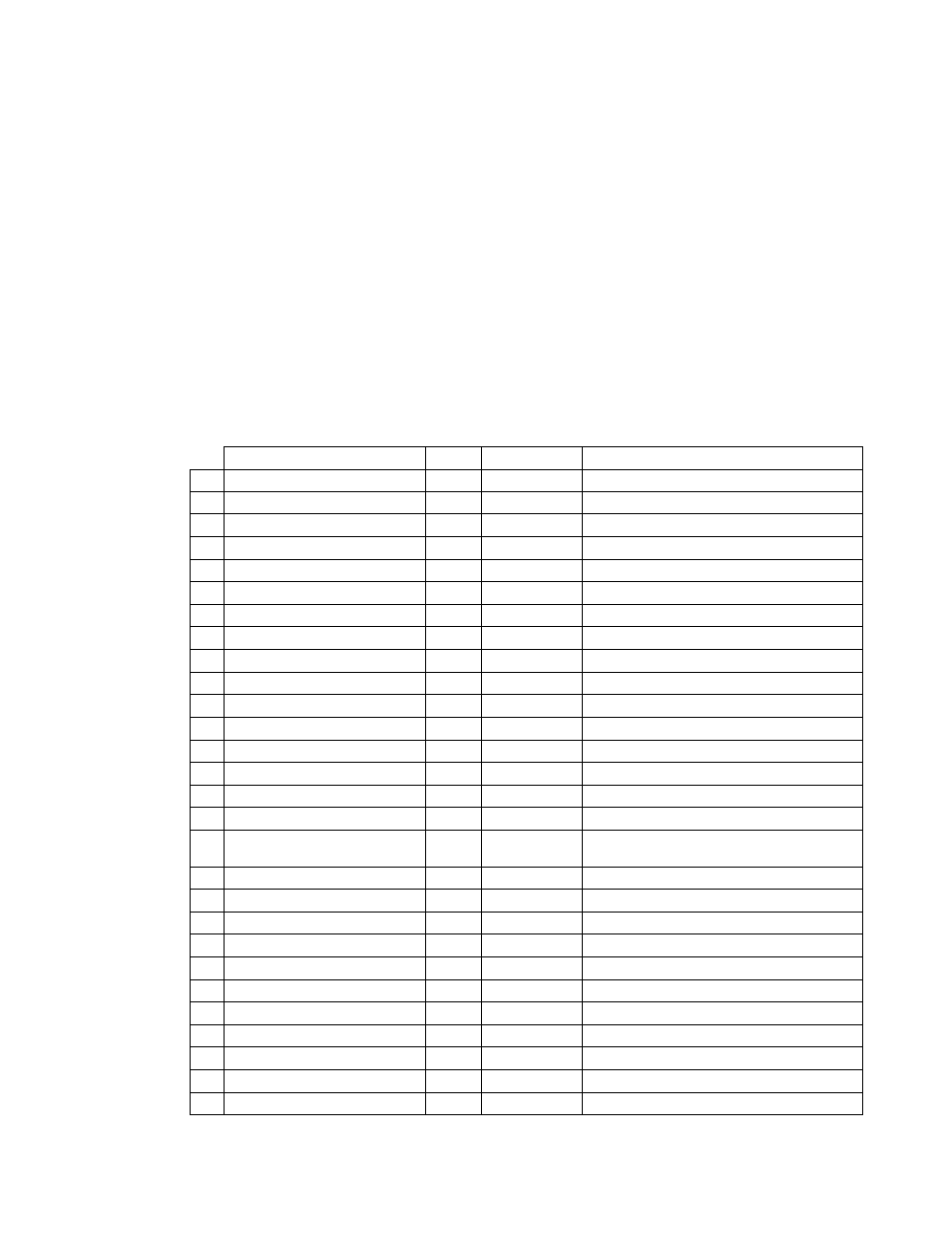

Input Parameters

Name

Type

Range

Description

1 TenStp_DC

REAL

NA

Tension set point [Data Counts](RAW)

2 TenStpMin_DC

REAL

NA

Min Tension set point [Data Counts]

3 TenStpMax_DC

REAL

NA

Max Tension set point [Data Counts]

4 TenRfStall_Pct

REAL

0 to 100

Tension Reference Stall Percent

5 TenRfStallMin_Pct

REAL

0 to 100

Tension Reference Stall Min Percent

6 TenRfTaper_Pct

REAL

0 to 100

Tension Reference Taper %

7 DanStpt_Pct

REAL

0 to 100

Dancer Set point [% of Full Storage]

8 RfRate_PctSec

REAL

0 to 100

Reference Rate [% per Second]

9 TenDanFb_DC

REAL

NA

Tension/Dancer Fdbk [Data Counts]

10 TenDanFbMin_DC

REAL

NA

Minimum Tension/Dancer Feedback

11 TenDanFbMax_DC

REAL

NA

Maximum Tension/Dancer Feedback

12 TrqFb_PU

REAL

-2.0 to 2.0 Torque Feedback [Per Unit]

13 TrimKP

REAL

0 to 50

Trim Regulator Proportional Gain

14 TrimWld_Rad

REAL

0 to 5

Trim Regulator Lead Frequency

15 TrimLimSpd_Pct

REAL

0 to 100

Speed Trim Limit [% Max Line Speed]

16 TrimLimSpdZero_Pct

REAL

0 to 100

Speed Trim Limit at Zero Speed

17 LineSpdTrimLimSpd_Pct

REAL

0 to 100

Line Speed where full speed trim will

be available

18 TrimLimTrq_Pct

REAL

0 to 100

Torque Trim Limit [% of Max Tension]

19 TrimRate_PctSec

REAL

0 to 100

Trim Rate [% Unit/Second]

20 TrimFbWLead_Rad

REAL

0 to 10

Feedback Lead Frequency [Rad/Sec]

21 TrimFbWLag_Rad

REAL

0 to 200

Feedback Lag Frequency [Rad/Sec]

22 DrvTrqRfJLoss_PU

REAL

-2.0 to 2.0 Inertia & Losses Torque Ref to Drive

23 LineSpd_EU

REAL

NA

Line Speed [Engineering Units]

24 LineSpdMax_EU

REAL

NA

Line Speed Maximum

25 MtrSpdBase_RPM

REAL

NA

Base Speed from Motor Name Plate

26 Constant_RPMperEU

REAL

XXX

Converstion Constant

27 BuildUpRate

REAL

XXX

Build Up Ratio

28 TrqRf_Pct

REAL

-100 to 100 Torque Reference [% Rated Torque]