3 mechanical dancer, 4 open loop torque – Rockwell Automation 9329 Drive Application Software Tension Control Gen. Units User Manual

Page 10

FM – Tension Control

Drive Application Software – page 10 of 52

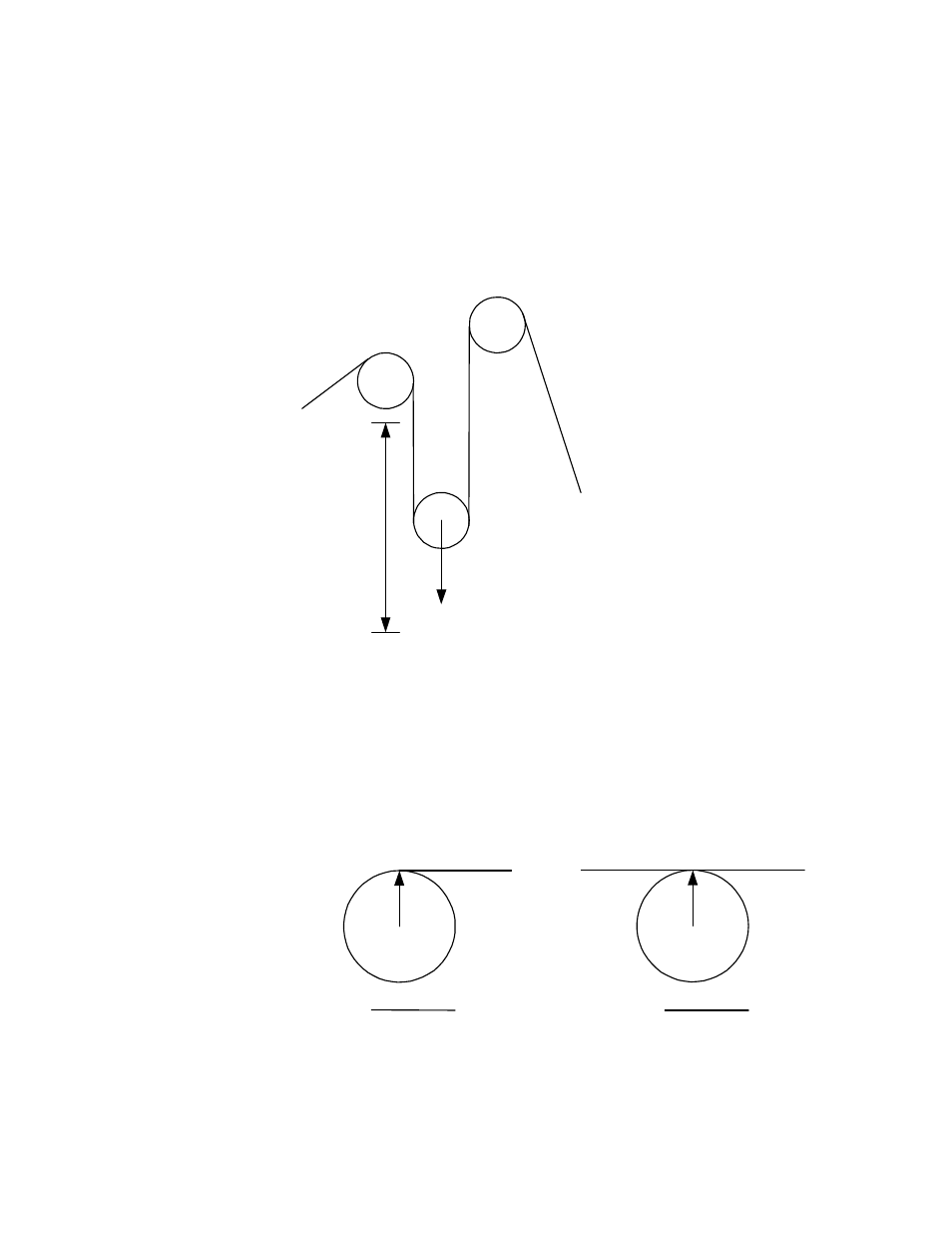

3.3 Mechanical Dancer

A dancer is a mechanical device that applies force to the web. The force could be a weight,

air pressure, or hydraulic pressure. If there is any difference in speed between the two

sections, the dancer will move. If the speed of the out going section is greater than the speed

of the incoming section the Dancer will move up and have less stored web. If the speed of

the out going section is less than the incoming section the Dancer will move down and will

store more web. The Tension Control Function Module monitors the dancer position and

adjusts the driven section to maintain the dancer at a user specific position (typically 50%

travel).

3.4 Open Loop Torque

Open loop torque does not require a tension or position feedback device. The amount of

torque required to change the tension between rolls may be calculated. The difference in

tension between sections plus losses is converted into percent motor torque. For Unwind

and Rewinds, the amount torque required is the tension required plus losses converted into

percent motor torque.

Force

Travel

Range

Dancer

Idler

Idler

T1

T1

T2

R

R

Winder / Unwind

Inline Tensioning

R = Radius in feet

G = Gear Ratio

T

mr

= Torque Motor Rated

% Torque =

* 100

T1

R * G * T

mr

% Torque =

* 100

(T1 - T2)

R * G * T

mr