Checking clamping pressure – Rockwell Automation 7000A PowerFlex Medium Voltage AC Drive (A Frame) - ForGe Control (PanelView 550) User Manual

Page 139

Component Definition and Maintenance 4-13

7000 “A” Frame

7000A-UM151D-EN-P – March 2013

Checking Clamping Pressure

Periodically, the clamping force in the PowerCage should be inspected.

Ensure there is no power to the equipment.

A T T E N T I O N

A T T E N T I O N

To prevent electrical shock, ensure the main

power has been disconnected before working on

the drive. Verify that all circuits are voltage free

using a hot stick or appropriate voltage-

measuring device. Failure to do so may result in

injury or death.

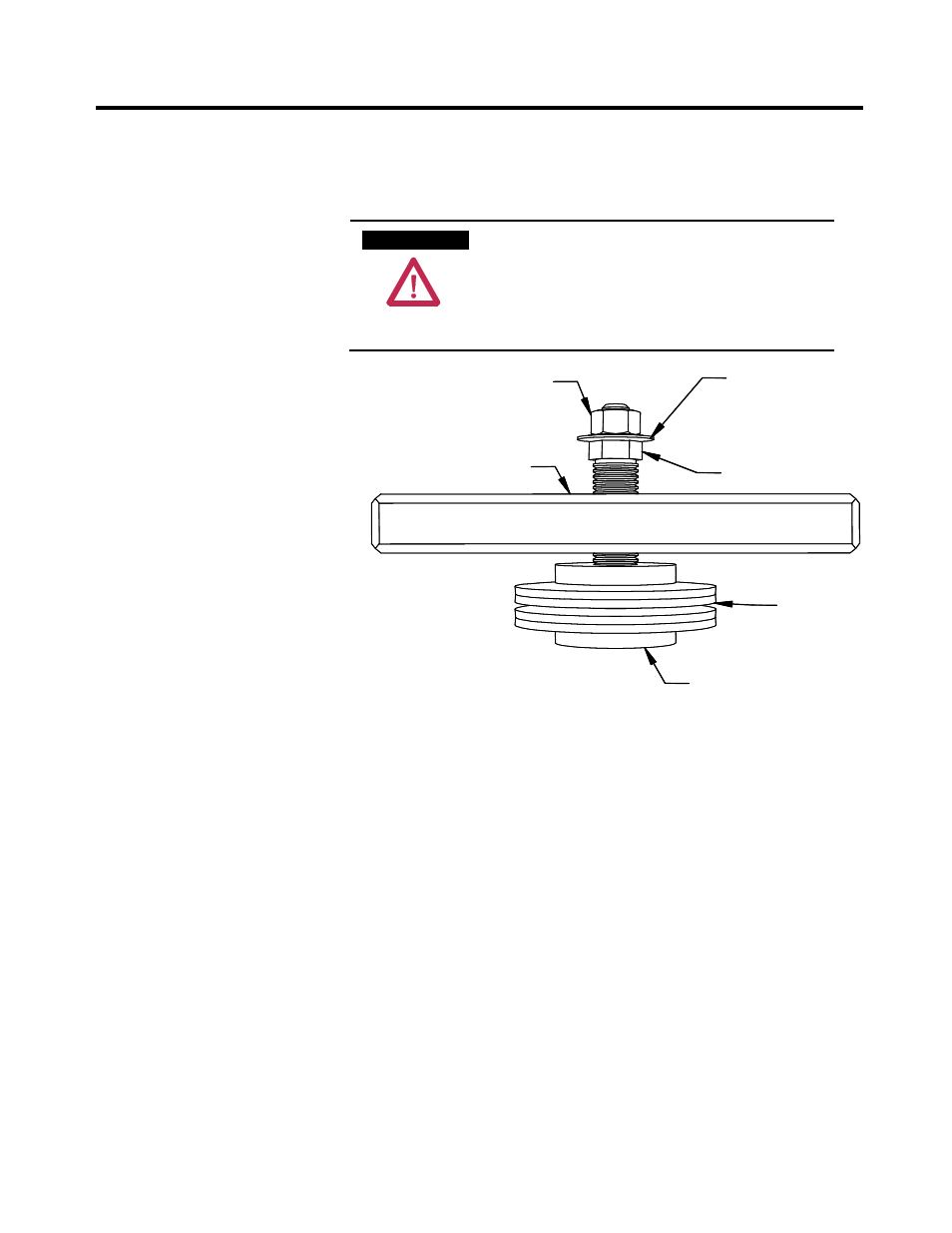

Clamp Bar

Calibration Nut -

DO NOT ADJUST

Indicating Washer

Adjusting Nut

Disc Springs

Pressure Pad

Figure 4.11 – Clamp Head Illustration

If proper force (as designated on the clamp head block) is applied to the

clamping assembly, the indicating washer should just be able to rotate

with fingertip touch. The indicating washer should not rotate freely.

Some force will need to be applied with your fingertips.

Clamping Pressure Adjustment

1.

Ensure that all power to the drive is off.

2.

Do not loosen the adjustment nut. If the clamping pressure is let off,

the assembly procedure must be carried out to ensure uniform

pressure on the thyristors.

3.

Tighten with a 21-mm wrench on the adjustment nut (upward motion)

until the indicating washer can be turned by fingers with some

resistance. IT SHOULD NOT SPIN FREELY

.