Uniform clamping pressure – Rockwell Automation 7000A PowerFlex Medium Voltage AC Drive (A Frame) - ForGe Control (PanelView 550) User Manual

Page 138

4-12

Component Definition and Maintenance

7000A-UM151D-EN-P – March 2013

7000 “A” Frame

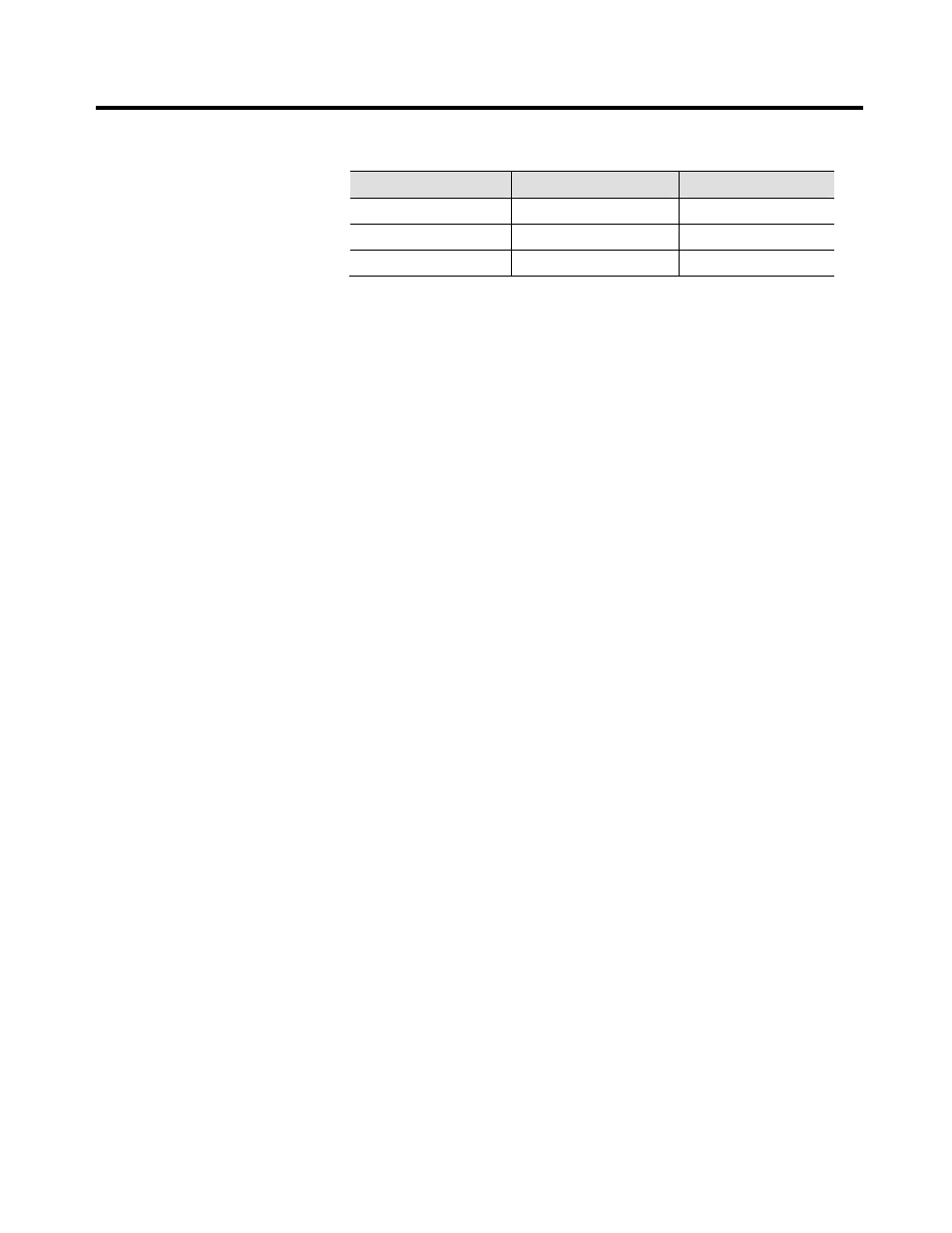

SGCT

Device Diameter

Clamp Force

400 A SGCT

38 mm

8.6 kN

800 A SGCT

47 mm

13.5 kN

1500 A SGCT

63 mm

20 kN

Pressure on the SGCTs must be uniform to prevent damage and to ensure

low thermal resistance. Uniform pressure can be achieved by loosening

the heatsink mounting bolts, tightening the clamp and then tightening the

heatsink bolts. See section “Uniform Clamping Pressure” for instructions.

External filtered air will be directed through the slots of the heatsinks to

carry away the generated heat from the SGCTs. The door filter is

necessary to ensure the slots on the heatsinks do not get plugged with dust

particles.

Uniform Clamping Pressure

It is very important to maintain proper pressure on the thyristors. Follow

this procedure whenever changing devices, or whenever the clamp is

loosened completely.

1.

Apply a thin layer of Electrical Joint Compound (Alcoa EJC No. 2 or

approved equivalent) to the clamp head pressure pad face.

2.

Torque the heatsink bolts to 13.5 N-m (10 ft-lb.) and then loosen each

bolt two complete turns.

3.

Tighten the clamp to the proper force until the indicating washers can

just be turned by the fingers with some resistance.

4.

Torque the heatsink bolts to 13.5 N-m (10 ft-lb.) starting with the

center heatsink and moving outward alternating left to right.

5.

Check clamp indicating washer.