Power wiring – Rockwell Automation 1305 AC Drive, Firmware 1.01-3.00 User Manual User Manual

Page 27

Chapter 2 – Installation/Wiring

2-11

POWER WIRING

Input and output power connections are performed through a

ten position terminal block, TB1 (see page 2-3 for location).

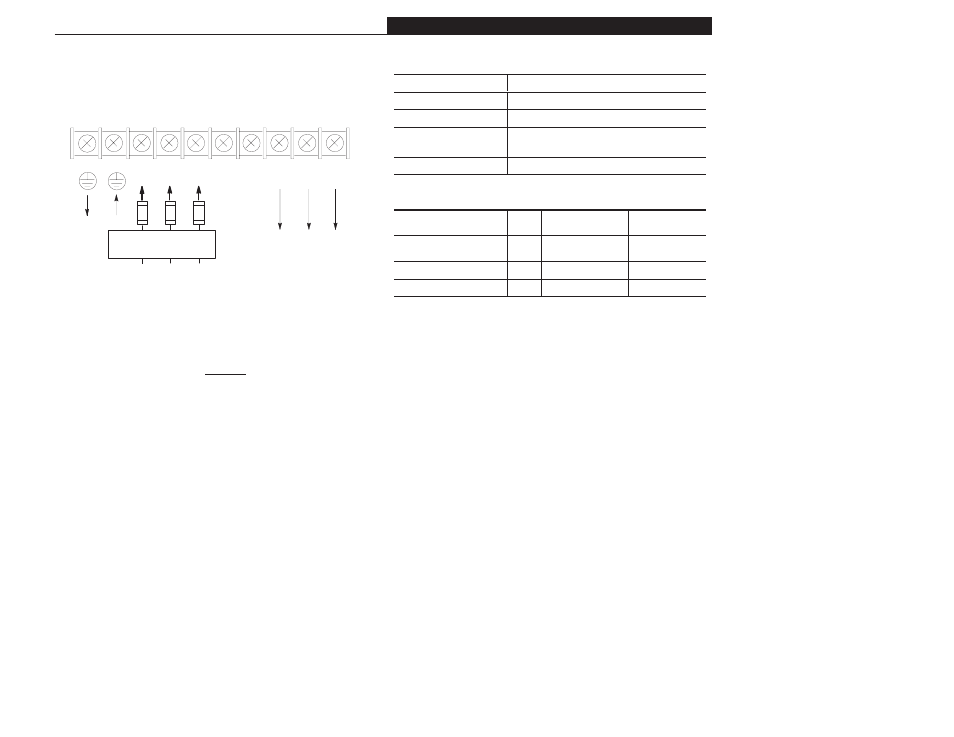

Figure 2.6 Power Terminal Block Designations (TB1)

GND

GND

L1

R

L2

S

L3

T

+DC BRK➀

(-DC)

T1

U

T2

V

T3

W

Required Branch

Circuit Disconnect

AC Input Line

To Motor

➀

Connection for Dynamic Brake Resistors for all models except the 200-230 Volt,

0.37 to 0.75 kW (1/2 to 1 HP) drive. IMPORTANT: The [DB Enable] parameter must

be enabled for proper operation.

➁

For single phase applications, the AC input line can be connected to any two of

the three input terminals R, S, T (L1, L2, L3).

➂

Bulletin 1305 drives are UL listed and CSA certified as a motor overload protec-

tive device. An external overload relay is not required for single motor applications.

IMPORTANT: This drive is not intended for use with single phase motors.

➃

Ground from drive to motor frame must be an independent continuous insulated

wire run.

To

Motor

➃

Required

Input Fusing

➁

➂

Table 2.B Power Block Terminal (TB1)

Terminals

Description

GND

Earth Ground

R, S, T (L1, L2, L3)

AC Input Line Terminals

+DC, BRK (or -DC)

Dynamic Brake Option - Refer to instructions included

with option

U, V, W (T1, T2, T3)

Motor Connection

Table 2.C Screw Size, Wire Size and Torque Specifications

Terminal

Screw

Size

Max./Min. Wire Size

mm

2

(AWG

)

Maximum Torque

N-m ( lb-ins. )

TB1

(0.37 to 0.75kW/1/2 to 1 HP)

M4

3.5/0.75 (12/18)

0.90 (8)

TB1 (All except above)

M4

4/0.75 (10/18)

1.81 (16)

TB2 (All)

M3.5

1.5/0.20 (14/24)

0.90 (8)