Rockwell Automation 1395 Digital Reference Adapter Board User Manual

Page 57

Chapter 6

StartĆUp

6-11

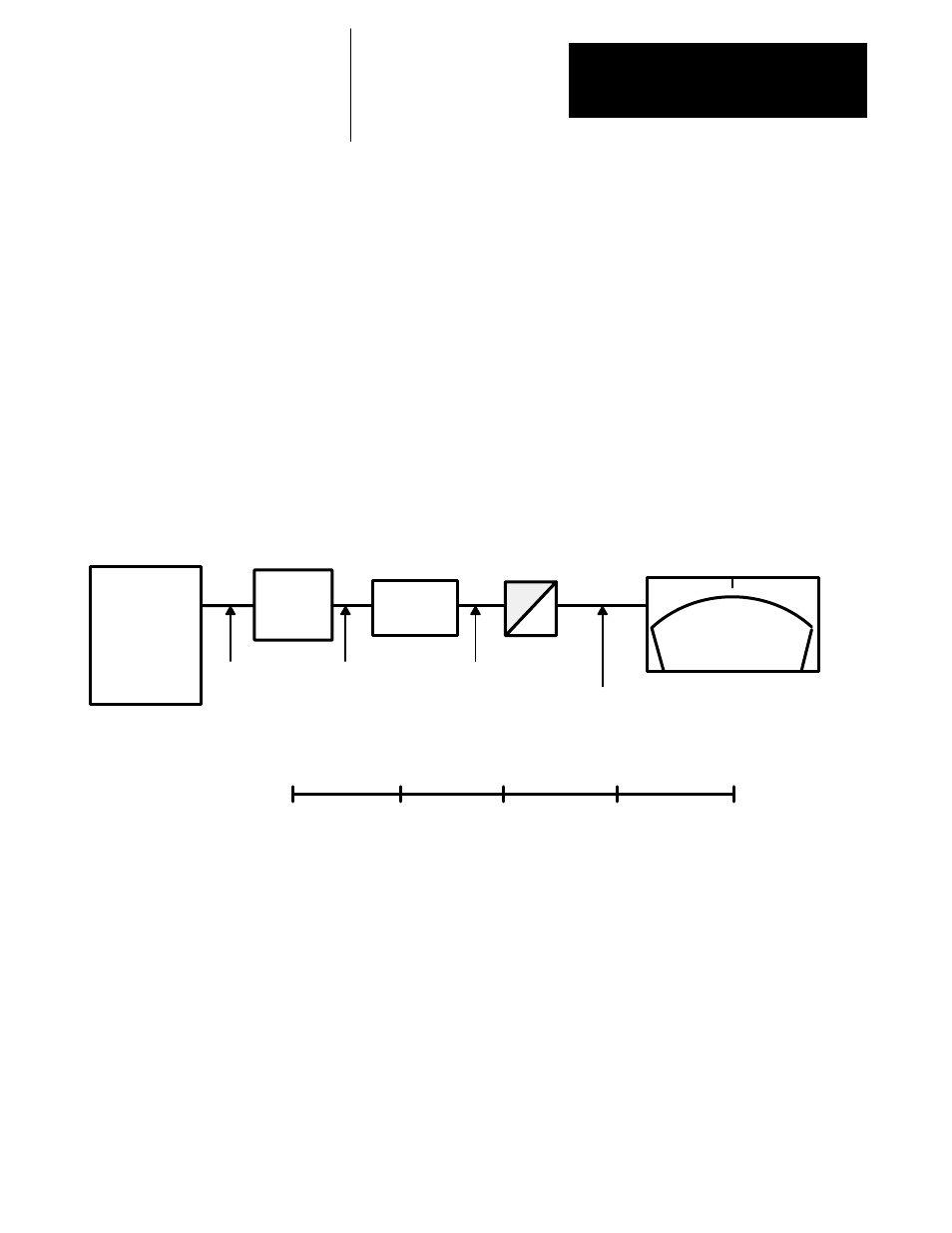

As was shown previously, another 0 to 10 VDC meter is connected to

Digital-To-Analog (D/A) output number 2. In this example, Parameter 452

which feeds the D/A is linked to Drive Parameter 112, Armature Current

Feedback. We assume in this example, that Armature Current Feedback

will vary between 0% and 200% rated current. This means the Drive digital

signal will vary between 0 and 8192 and the D/A signal must vary between

0 and 2048 for a 0 to 10 VDC output. In this case, programming Parameter

577 to a value of 0.25 will provide the correct scaling (0.25 x 8192 =

2048). Setup Parameter 578 can remain at zero volts offset because a DC

offset is not required in this example (Refer to Figure 6.6).

Figure 6.6

Example: Analog Output - Current Indication 0 - 10VDC range = 0 to 200% current

feedback

SCALE

P577 = 0.25

A

D

Offset

P578 = 0

+8192

0

+2048

0

Analog Range -10V

4096 = 100%

or 1 per unit

Example 2:

0 to 200% I

A

0 to 8192

-2048

0

Digital Range

Drive Units

0 to 200% IA

After Scaling

After Offset

Meter Voltage

% I

AFDBK

+2048

0

0V

5V

10V

200%

100%

0

0

0

0

0

0

+1024

+4096

+1024

+1024

+5V

100%

+10V = 200% I

AFDBK

0V = 0% I

AFDBK

0

+5V

+10V

+2048

+8192

+2048

+2048

+10V

200%

Digital Reference Input – The digital reference input allows an external

source to provide the Drive with a digital reference or trim signal. This

signal can be provided by an encoder or frequency reference source with a

maximum input frequency of 50 Khz.