Rockwell Automation 150 MNL/SMC DIALOG+/APP-PROD GUIDE User Manual

Page 173

Reference

10-11

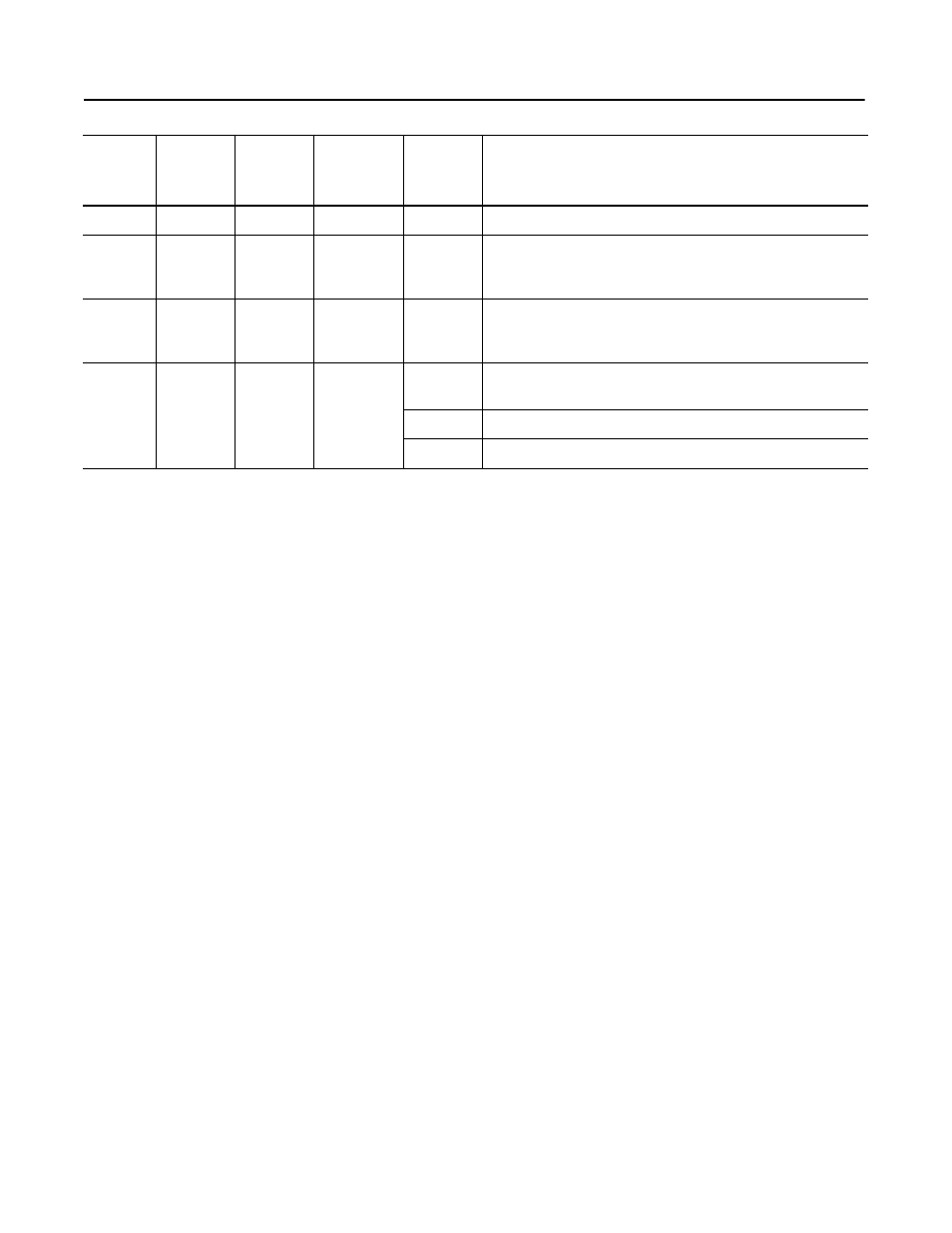

Table 10.M Motor Output - Comparison of NEMA Polyphase Designs

Calculating Torque

(Acceleration Torque

Required for Rotating Motion)

Some machines must be accelerated to a given speed in a certain

period of time. The torque rating of the drive may have to be

increased to accomplish this objective. The following equation may

be used to calculate the average torque required to accelerate a known

inertia (WK

2

). This torque must be added to all the other torque

requirements of the machine when determining the drive and motor’s

required peak torque output.

Where:

T = Acceleration Torque (ft.-lb.)

WK

2

= total system inertia (ft.-lb.

2

) that the motor must accelerate. This

value includes motor armature, reducer, and load.

D

N = Change in speed required (RPM

t = time to accelerate total system load (seconds).

Note:

The number substituted for (WK

2

) in this equation must be in

units of ft.-lb.

2

. Consult the conversion tables for the proper

conversion factor.

NEMA

Design

Starting

Torque

Locked

Rotor

Torque

Breakdown

Torque

% Slip

Applications

A

High

High

High

< 5%

Broad applications including fans, blowers, pumps, and machine tools.

B

Normal

Normal

Normal

< 5%

Normal starting torque for fans, blowers, rotary pumps, unloaded

compressors, conveyors, metal cutting, machine tools, miscellaneous

machinery.

C

Low

High

Low

Low

High inertia starts such as large centrifugal blowers, fly wheels and

crusher drums. Loaded starts such as piston pumps, compressors and

conveyors.

D

Normal

High

None

High

Very high inertia and loaded starts. Choice of slip range to match

application.

5–8%

Punch press, sheers and forming machine tools.

8–13%

Cranes, hoists, elevators and oil well pumping jacks.

T

WK

2

∆

N

( )

×

30

8t

Ч

---------------------------

=