Rockwell Automation 150 MNL/SMC DIALOG+/APP-PROD GUIDE User Manual

Page 156

Reduced Voltage Starting

8-3

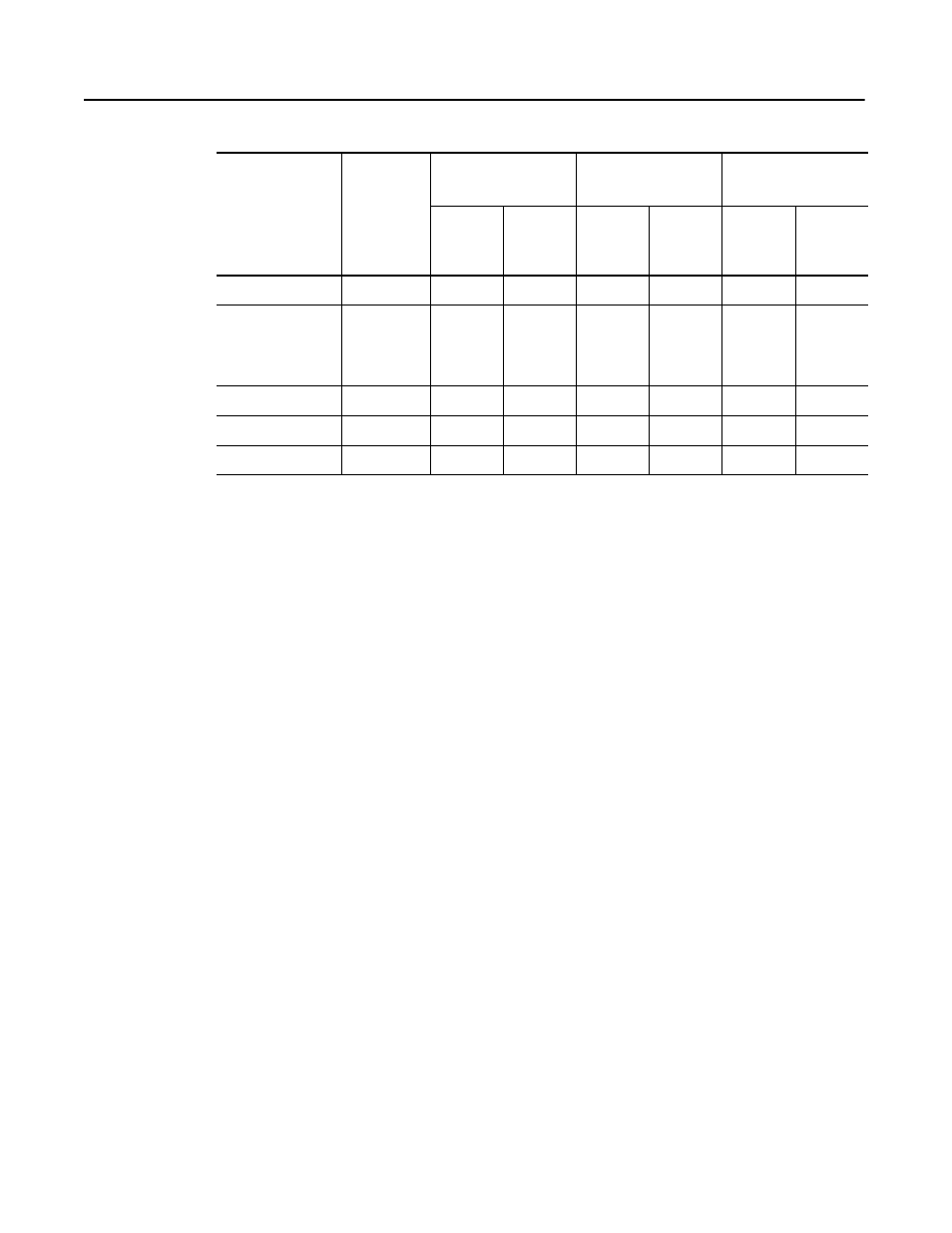

Table 8.K

Typical Voltage, Current and Torque Characteristics for NEMA

Design B Motors

With the wide range of torque characteristics for the various starting

methods, selecting an electromechanical reduced voltage starter

becomes more application dependent. In many instances, available

torque becomes the factor in the selection processes.

Limiting line current has been a prime reason in the past for using

electromechanical reduced voltage starting. Utility current

restrictions, as well as in-plant bus capacity, may require motors

above a certain horsepower to be started with reduced voltage. Som

areas of the world require that any motor above 7-1/2 HP be started

with reduced voltage.

Using reduced voltage motor starting also enables torque control.

High inertia loads are a good example of an application in which

electromechanical reduced voltage starting has been used to control

the acceleration of the motor and load.

Electromechanical reduced voltage starters must make a transition

from reduced voltage to full voltage at some point in the starting

cycle. At this point, there is normally a line current surge. The

amount of surge depends upon the type of transition being used and

the speed of the motor at the transition point.

Starting

Method

% Voltage at

Motor

Terminals

Motor Starting

Current as a % of:

Line Current

as a % of:

Motor Starting

Torque as a % of:

Locked

Rotor

Current

Full

Load

Current

Locked

Rotor

Current

Full

Load

Current

Locked

Rotor

Torque

Full

Load

Torque

Full Voltage

100

100

600

100

600

100

180

Autotrans.

80% tap

65% tap

50% tap

80

65

50

80

65

50

480

390

300

64

42

25

384

252

150

64

42

25

115

76

45

Part Winding

100

65

390

65

390

50

90

Wye-Delta

100

33

198

33

198

33

60

Solid-state

0–100

0–100

0–600

0–100

0–600

0–100

0–180