10 - reference, Introduction, Motor output speed/torque/horsepower – Rockwell Automation 150 MNL/SMC DIALOG+/APP-PROD GUIDE User Manual

Page 163: Torque and horsepower, Reference, Chapter

Chapter

10

Reference

Introduction

Certain mechanical parameters must be taken into consideration when

applying motor controllers. The following section explains thes

parameters and how to calculate or measure them.

Motor Output

Speed/Torque/Horsepower

The speed at which an induction motor operates depends on the input

power frequency and the number of poles for which the motor is

wound. The higher the frequency, the faster the motor runs. The

more poles the motor has, the slower it runs. To determine the

synchronous speed of an induction motor, use the following equation:

Actual full-load speed (the speed at which the motor will operate at

nameplate rated load) will be less than synchronous speed. This

difference between synchronous speed and full-load speed is called

slip. Percent slip is defined as follows:

Induction motors are built with slip ranging from less than 5% to as

much as 20%. A motor with a slip of less than 5% is called a normal

slip motor. Motors with a slip of 5% or more are used for applications

requiring high starting torque.

Torque and Horsepower

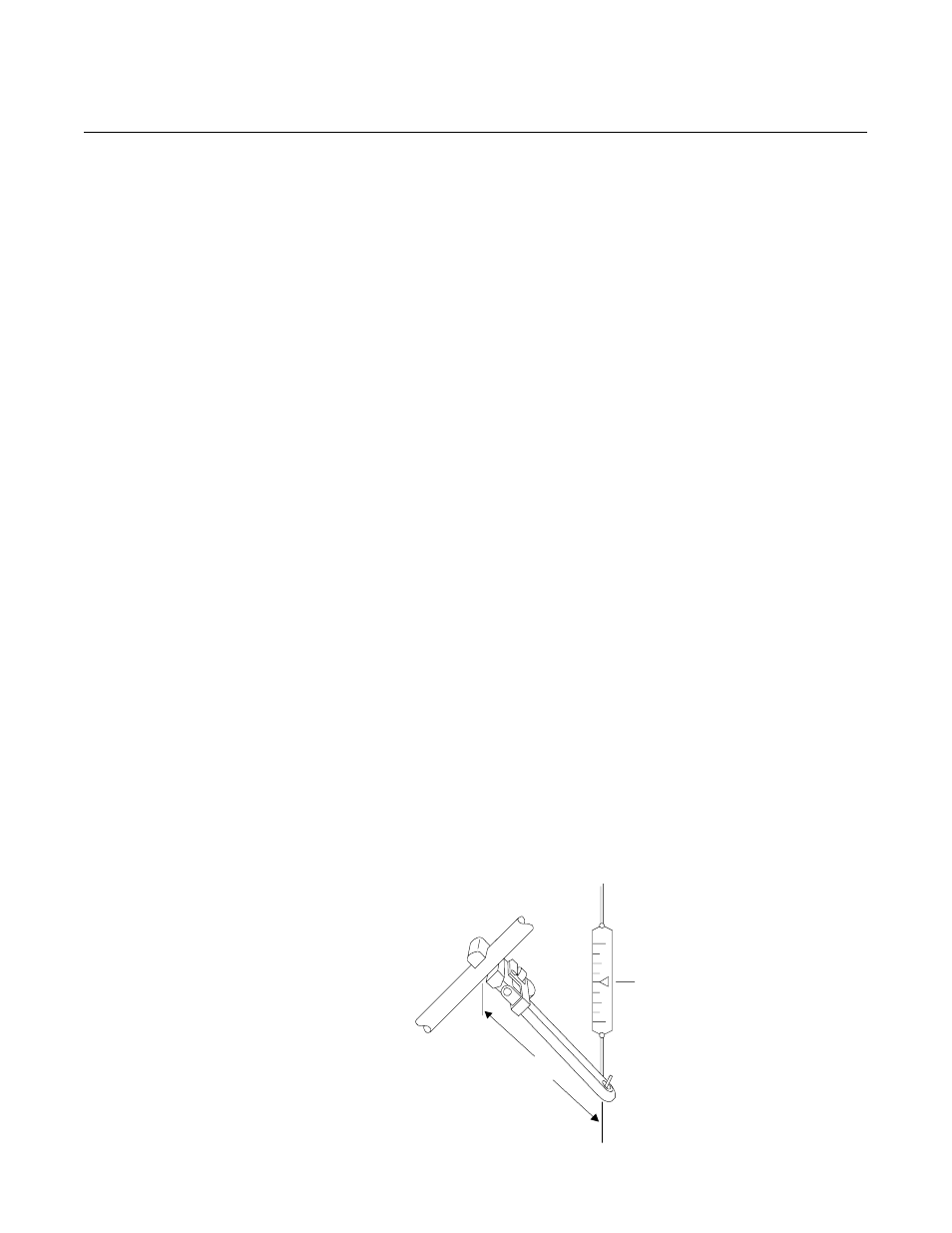

Torque and horsepower, two important motor characteristics,

determine the size of the motor required for a given application. Th

difference between the two can be explained using a simple

illustration of a shaft and wrench.

Figure 10.1 Shaft and Wrench

Synchronous Spee

60

2

×

Frequenc

×

Number of Poles

-----------------------------------------

=

Percent Sli

Synchronous Speed

Full Load String

–

Synchronous Speed

--------------------------------------------------------------------------------

100

×

=

One Pound

One Foot