160 ssc drive parameters, Chapter 5, Profibus parameter descriptions and data protocol – Rockwell Automation 160PD1 160 Profibus Communication Module User Manual

Page 21: 160 ssc drive parameters -1, Chapter

Chapter

5

Profibus Parameter Descriptions

and Data Protocol

This chapter provides a listing and description of the Bulletin 160

Drive parameters related to Network Operation, and the PD1 Module

Data Protocol information.

Important: Refer to your 160 SSC™ Variable Speed Drive (Series C)

User Manual for drive parameter descriptions.

160 SSC Drive Parameters

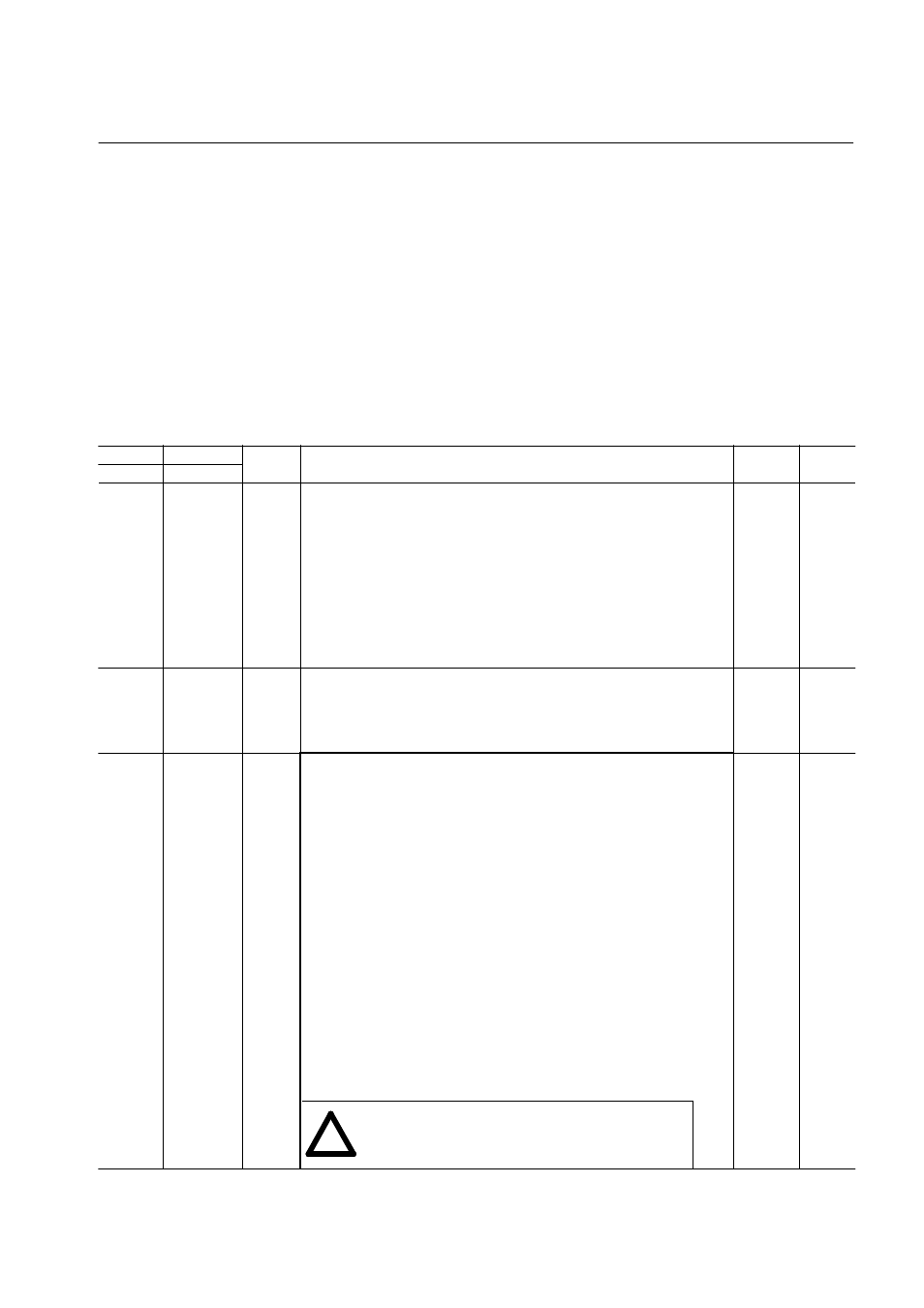

Drive

PD1 (Tab. 5E)

Access

[Parameter Name] and Description

Min./Max.

Values

Default

Param. No Param. Oper.

46

4

5

Read

write

[Input Mode]

Configures the TB3 control inputs for various 3-wire or 2-wire control schemes.

Also enables/disables the program keypad module input control.

Settings: must be set to either

2 = Program Keypad Module control or

6 = 2-wire TB3 Control/Keypad or Communication control

A contact closure on TB3 terminals 7 and 8 is required for the drive to respond to a

Run command.

Important: This parameter cannot be programmed while the drive is running.

In addition, power must be cycled or P56 - [Reset Function] must be

set to 2 for the change to take effect.

0/9

0

59

4

5

Read

Write

[Frequency Select]

Selects the source of the frequency command for the drive.

The reference to P58 - [Internal Frequency] is bipolar, so a positive reference gives

forward rotation, and a negative reference gives reverse direction.

Settings:must be set to 1 = internal freq. command from P58 - [Internal Frequency].

0/1

0

66

4

5

Read

Write

[RPM Scaling]

A scaling factor is required to interpret a speed reference in RPM at the [Maximum

Frequency] of the drive. The 160 Drive parameter P66 - [Preset Frequency 5] is

used by the PB1 Module for this purpose.

P66 = rRPM / rf

rf:

required motor frequency to achieve rRPM

rRPM:

final RPM at application output (e.g. speed at gear box output),

which will be displayed at Profibus Master

Application Speed [rpm] = Drive Output Frequency x P66 [RPM Scaling]

e.g.

1500 rpm = 50 Hz x 30

(4 pole motor) P66 = 30.0 (300)

900 rpm = 60 Hz x 15

(8 pole motor) P66 = 15.0 (150)

Gear Box 1:20: 75 rpm = 50 Hz x 1.5

(4 pole motor) P66 = 1.5 (15)

For network operation the P66 values in brackets are valid, which are ten times the

values for keypad operation.

If P66 - [RPM Scaling] is set to 0, speed reference may be sent via the network

directly in 1/10 of Hz.

e.g. SpeedRef [Hz] (Profibus) = 405 results in 40.5 Hz of output frequency.

Speed feedback is considered to be P01 - [Output Frequency],

which reflects the output frequency considering ramp rates.

0-240

[0-2400]

50

ATTENTION: Unpredictable motor speed can cause death,

injury or equipment damage. Do not use P66 as the [Preset

Frequency 5] function via control terminal wiring.

!