Warning – Burnham 8H User Manual

Page 9

6. Lift boiler with pry bar. Remove wood blocks.

Lower boiler.

C.

For Packaged Boiler only, proceed to Paragraph E.

D.

Test Section Assembly for leaks before connecting to

system and installing controls, trim and jacket. Refer to

Figure 3 and Table 3.

1. Plug Tappings C & E (¾ NPT) and Return Tapping

B (2 NPT).

2. Insert ¾” NPT x ¼” NPT bushing in Tapping D.

Install pressure gauge capable of indicating 50 psi.

3. Insert 2” NPT x ¾” NPT bushing in Supply Tapping

A. Install purge valve with a hose that runs to a

drain.

4. Connect fill valve and piping to Drain Tapping G.

WARNING

Do not use air to leak test boiler.

5. Fill boiler completely with water by venting air

through purge valve. Close purge valve and apply

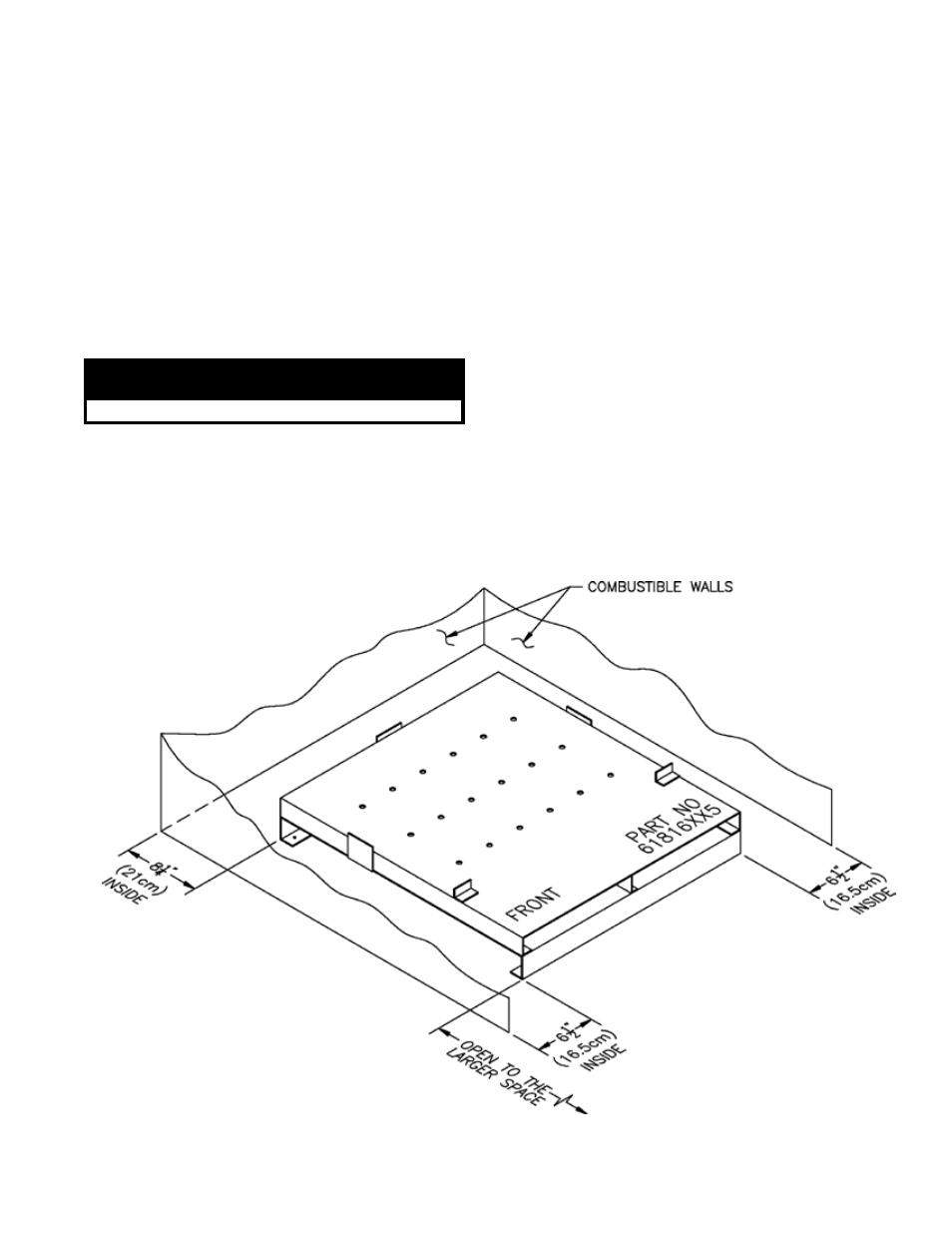

Figure 4: Installation of Special Base for Combustible Flooring

water pressure of at least 10 psi but less than 50 psi

gauge pressure.

6. Examine boiler for leaks or damage due to shipment

or handling.

7. Remove plugs from Return Tapping B, Tapping C,

and Tapping E (if second limit or operating control

is used). Also remove fill valve and piping, purge

valve and piping, and pressure gauge.

E.

Install special base if installation is on combustible

flooring. See Figure 4. Floor shield adds 4¾” to boiler

height.

1. Place special base on combustible floor with surface

marked “FRONT” in upward position.

2. Locate special base with spacing to combustible

materials as shown in Figure 4.

3. Place boiler on special base. Boiler must rest inside

locating brackets. Boiler jacket panels will overhang

special base.

4. Do not enclose boiler (including special base) on all

four sides. Models 805H - 807H may be enclosed

on three sides (alcove) while maintaining clearances

shown in Figure 4.