Mixing box control installation manual, Verification and troubleshooting – Titus Mixing Box Controls IOM User Manual

Page 6

Mixing Box Control Installation Manual

IOM-MBC-00

08-30-04

6 of 15

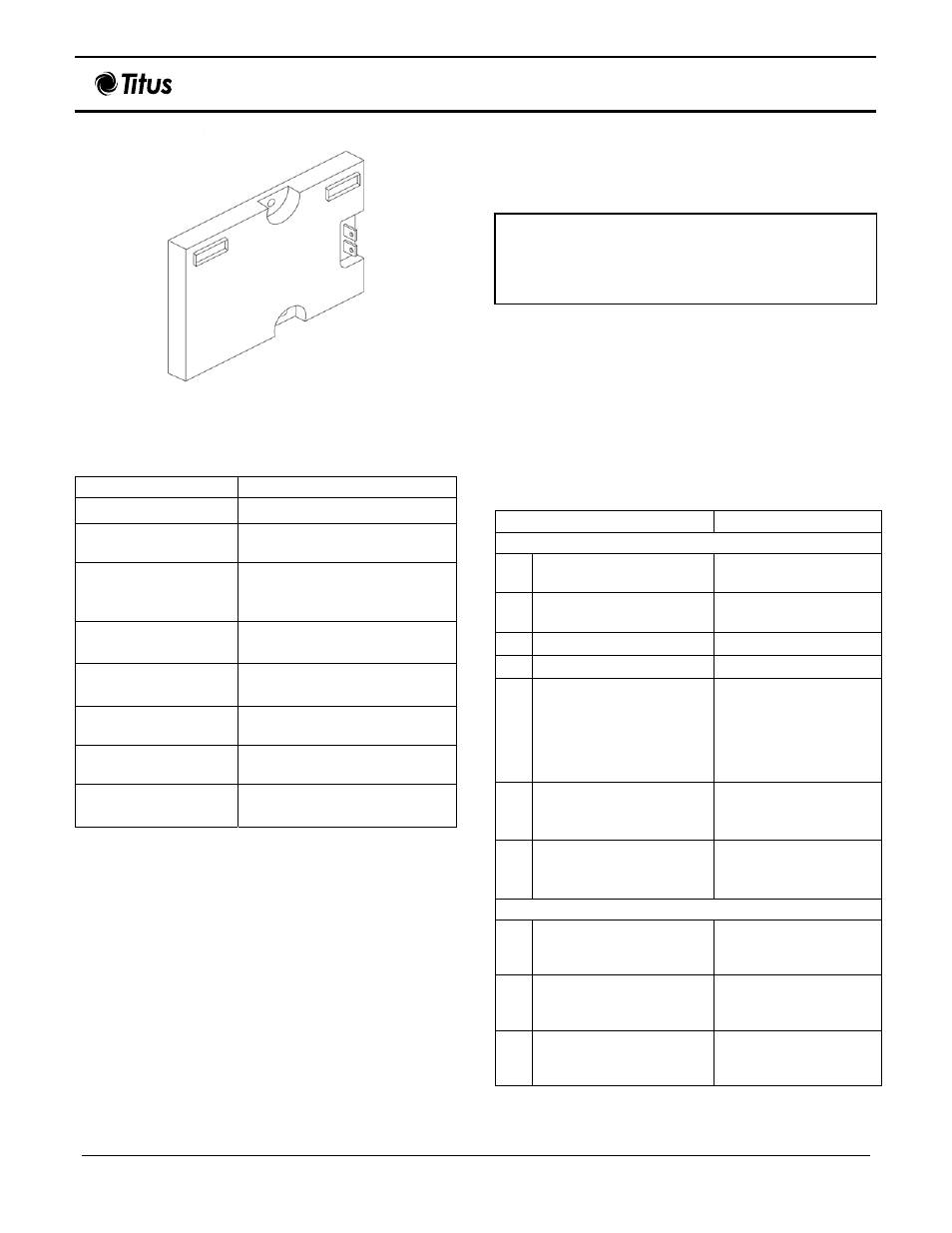

Figure 8. Solid-State Enthalpy Sensor

Table 6. Operating Ratings

Specific

Description

Case

Duct-mounted

Temperature Sensing

Element:

Thermistor

Output Signal

4 to 20 mA current signal;

increases from 4 to 20 mA as

enthalpy decreases

Operating ambient

temperature

-40 to 125° Fahrenheit (-40 to

+52° Celsius)

Shipping temperature

rating:

-40 to 150° Fahrenheit (-40 to

+66° Celsius)

Maximum power

consumption

0.45 Vac

Maximum supply

voltage

18 to 24 Vdc

Electrical connection

Two ¼-inch quick-connect

terminals

Listed by Underwriters Laboratories Inc.

Location and Mounting

The sensor mounts in any position up to 200 feet (61

meters) away from the logic module – W7459C and may

be used for the following operational circumstances.

•

Proportional damper control: Attach the logic

module to the Damper Motor’s side.

•

Outdoor air sensing: Mount in any orientation where

it is exposed to freely circulating air, but is protected

from rain, snow, and direct sunlight.

•

Return air sensing: For differential enthalpy control,

a second C7400A enthalpy sensor can be connected

to the W7459 and mounted in the return air duct.

Note: Contact your Titus representative if

specifications call for differential enthalpy control.

Verification and Troubleshooting

The following table provides the actions and responses to

verify the installation of W7459C logic module installed on

an M8405 Actuator.

DANGER

DISCONNECT POWER SUPPLY BEFORE

CONNECTING WIRING TO PREVENT ELECTRICAL

SHOCK OR EQUIPMENT DAMAGE

Caution: Exercise care when adjusting the

enthalpy changeover and minimum damper

position control. Use a small screwdriver for

these adjustments. Excessive force may damage

the controls.

Perform verification and troubleshooting steps in

order.

Table 7. Three-Position Control Verification

and Troubleshooting

e

s

n

o

p

s

e

R

n

o

it

c

A

A.

Power

1.

Disconnect power at

terminals TR and TR1.

2.

Disconnect wires from

terminals 6, X and D.

3.

Jumper TR and 1.

4.

Jumper 6 and D.

5.

If connected, remove

C7400A enthalpy sensor

from terminals S

O

and +.

Factory-installed 620-ohm

resistor should be

connected to S

R

and +.

6.

Apply 24 Vac power to

terminals TR and TR1.

LED should be off.

Motor is in closed

position.

7.

Disconnect factory-

installed 620-ohm resistor

from terminals S

R

and +.

LED should be on.

Motor drives toward

open.

B.

Enthalpy Simulation

1. To simulate high and low

enthalpy (single enthalpy

sensor)).

2. Reconnect factory-

installed 620-ohm resistor

across terminals S

R

and +.

3. Connect 1.2k ohm

checkout resistor across

terminals S

O

and +.