Titus Lynergy User Manual

Start-up, operation and service instructions

1

Titus Proportional Lynergy

W/ Discharge Temperature Limit

Start-Up, Operation and Service Instructions

SAFETY NOTE

Air-handling equipment will provide safe and reliable service when operated within design specifications. The equipment

should be operated and serviced only by authorized personnel who have a thorough knowledge of system operation, safety

devices, and emergency procedures. Good judgment should be used in applying any manufacturer’s instructions to avoid injury

to personnel or damage to equipment and property.

WARNING: Disconnect all power to the unit before performing maintenance or service. Unit may automatically start if

power is not disconnected. Electrical shock and personal injury could result.

WARNING: Units with LineaHeat use Solid State relays, which generate heat when used. The temperature of the

control box and/or heat sinks may be hot.

OVERVIEW

LineaHeat is an electronic, time proportional electric heat system. The heat output of the heater is modulated utilizing quiet,

rapid performing solid state relays. The relays are switched off and on to allow the heating of electrical resistance elements.

The proportion of time the relay is on dictates the proportion of maximum heat the electric heater can produce. The solid state

relays are switched off and on by a supplied Electric Heat Module (EHM). The EHM accepts an input signal from the terminal

unit controller or thermostat for the amount of heat desired. The EHM can accept a variety of different input signals when

interfacing with controls. The type of input the EHM will accept is modified by changing the position of one or two jumpers

easily accessible on the board.

The LineaHeat is available with an optional discharge temperature sensor. When used with the discharge sensor option, the

LineaHeat will modulate outgoing temperature from the unit between the maximum temperature setting and initial temperature

of incoming air before heating began. The discharge temperature set point is easily adjusted in the field by rotating the

temperature dial on the EHM. The EHM will not allow temperatures over the set point so as to prevent overheating,

stratification, and energy waste from heated air lost through overhead returns.

START-UP

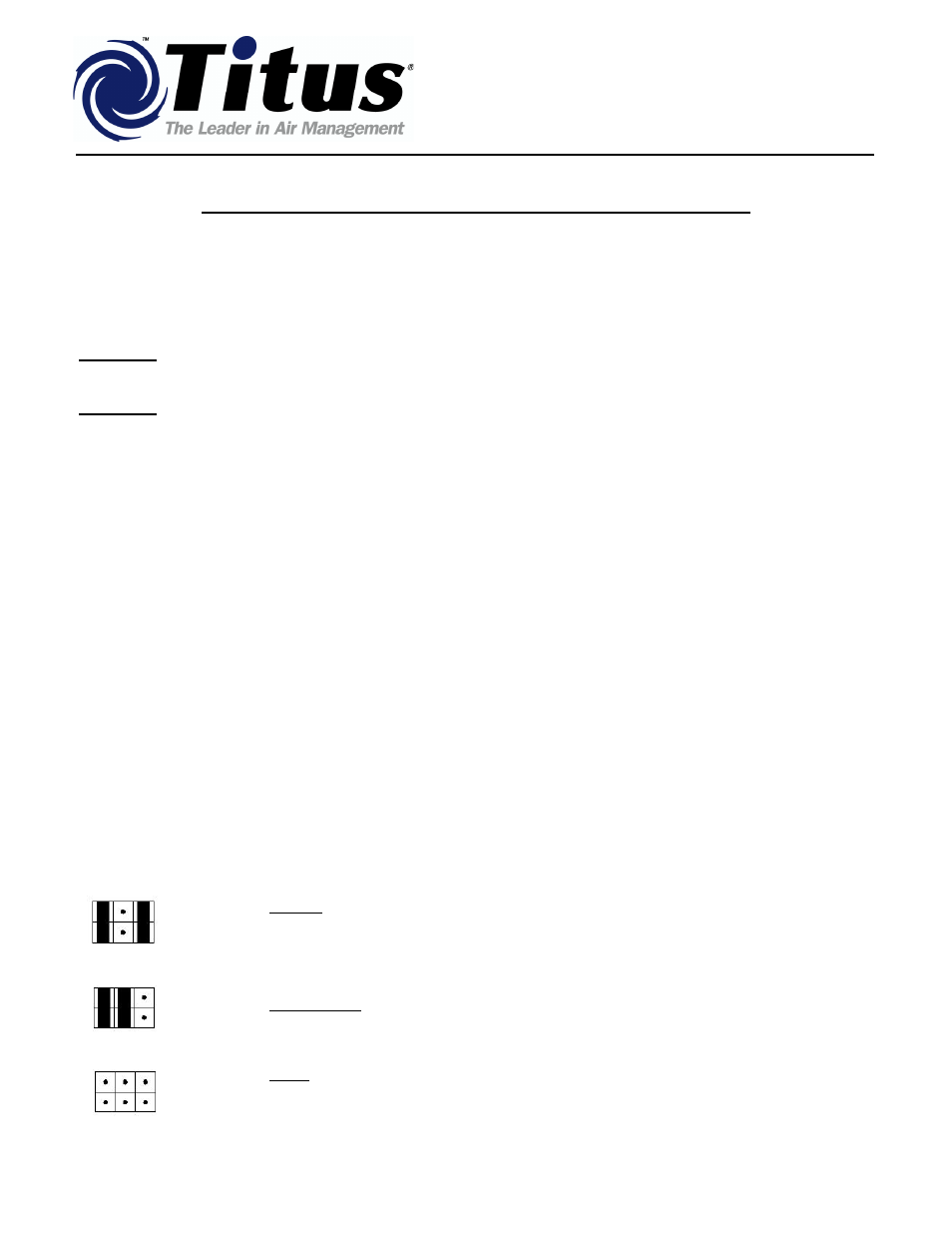

INPUT SETTING. The LineaHeat board is capable of being controlled and operated 7 different ways. The units are ordered

with an LXY code, where “X” is coded for unit power and “Y” is coded for the application. This “Y” application can be

changed in the field. The application desired is chosen by placement of jumpers in the corner of board (See Drawing 1 on page

2). Jumper settings below are representative of pins at bottom left of control board as shown in drawing. Wiring diagrams for

each are on pages 5 & 6.

LX3)

0-10V: This application accepts a 0-10 Vdc (0-20mA) signal to modulate the heater

output. The output is proportional to input signal (i.e., 4.5 volts sets the heater to 45% of

kW rating).

LX2)

2 Stage (2Stg): This two stage application accepts two 24 Vac inputs to step the heater

output from off to 50% or 100% heater kW rating. A signal to “Inc” is 50% and a signal

to “Dec” is 100%

LX1)

On/Off: This application accepts one 24 Vac input at “Inc” to step the heater output from

OFF to 100% heater kW rating. The signal may be pulsed off and on over a small time

period to provide proportional heat. For example, a signal that is on for 4.5 seconds every

10 seconds would produce 45% of the heater’s kW rating.