Mixing box control installation manual, Abbreviations, Verification and troubleshooting – Titus Mixing Box Controls IOM User Manual

Page 15

Mixing Box Control Installation Manual

IOM-MBC-00

08-30-04

15 of 15

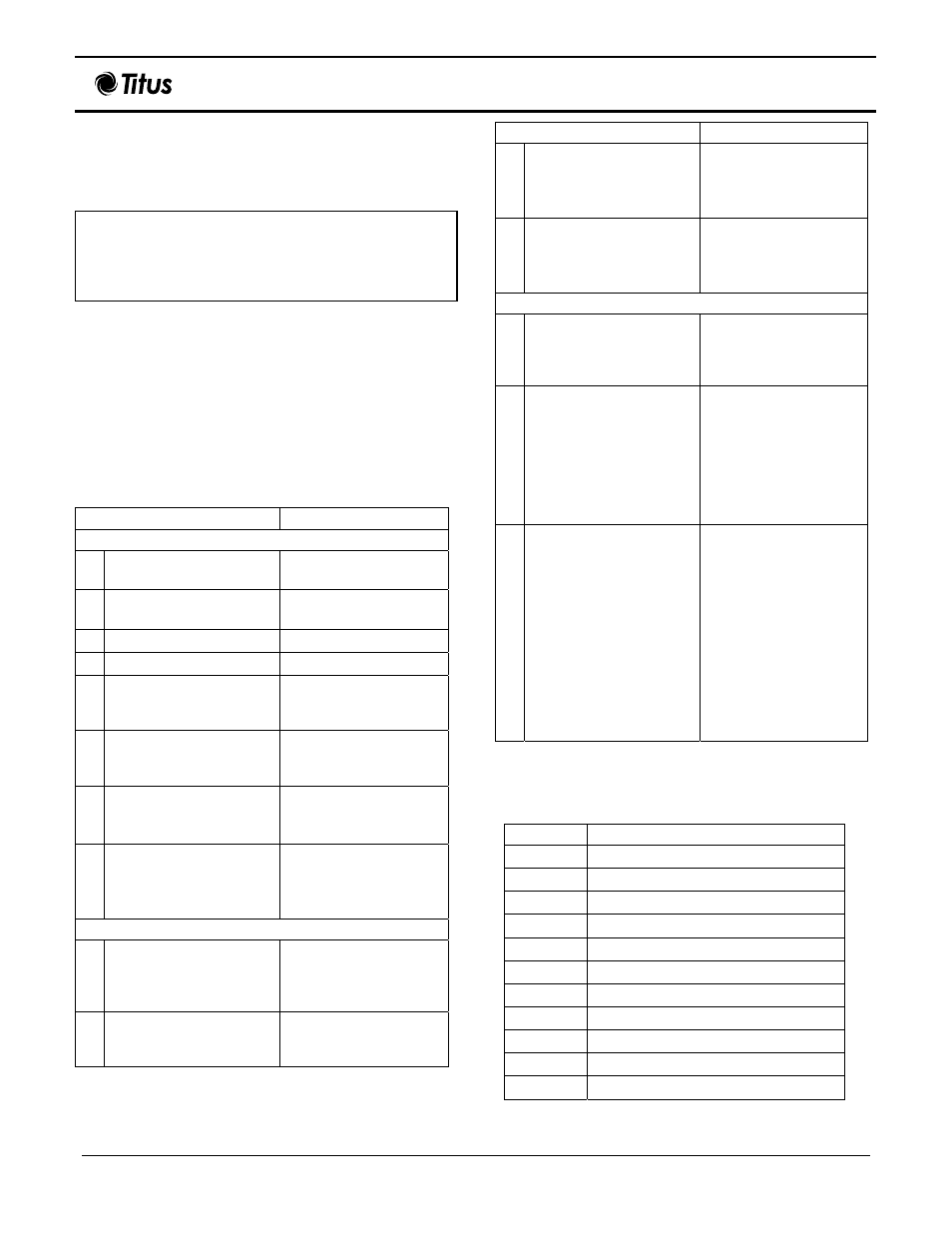

Verification and Troubleshooting

The following table provides the actions and responses to

verify the installation of W7459A installed on an M7415

Actuator.

DANGER

DISCONNECT POWER SUPPLY BEFORE

CONNECTING WIRING TO PREVENT ELECTRICAL

SHOCK OR EQUIPMENT DAMAGE

Caution: Exercise care when adjusting the

enthalpy changeover and minimum damper

position control. Use a small screwdriver for

these adjustments. Excessive force may damage

the controls.

Perform verification and troubleshooting steps in

order.

Table 16. Modulating Control Verification

and Troubleshooting

e

s

n

o

p

s

e

R

n

o

it

c

A

A.

Power

1. Disconnect power at

terminals TR and TR1.

2. Disconnect jumper

across P and P1.

3. Jumper TR and 1.

4. Jumper T1 to T.

5. If connect, remove

C7400A Enthalpy Sensor

from terminals S

O

and +.

6. Verify Factory-installed

620 ohm resistor is

connected to S

R

and +.

7. Apply 24 Vac power to

terminals TR and TR1

LED should be off.

Motor is in closed

position.

8. Disconnect factory-

installed 620 ohm

resistor from terminals S

R

and +.

LED should be on,

indicating low enthalpy.

Motor drives toward

open.

B.

Enthalpy Simulation

1. Reconnect factory-

installed 620-ohm

resistor across terminals

S

R

and +.

2. Connect 1.2k ohm

checkout resistor across

terminals S

O

and +.

e

s

n

o

p

s

e

R

n

o

it

c

A

3. Set enthalpy set point

potentiometer to “A”.

LED should come on,

indicating low enthalpy.

Motor drives toward

open.

4. Set enthalpy set point

potentiometer to “D”.

LED should go off,

indicating high enthalpy.

Motor drives toward

closed.

C.

Sensor

1. Reconnect the + lead of

outdoor enthalpy sensor

to the + terminal of

W7459.

2. Connect a DC multi-

meter or voltmeter

between terminals S

O

of

the W7459 and terminal

S of the enthalpy sensor.

(Positive meter lead to

terminal S of enthalpy

sensor.)

Multi-meter or voltmeter

should indicate between

3 and 25 mA, if sensor

is operating properly.

If multi-meter or

voltmeter indicates

zero, the sensor may be

wired backwards.

3. If using differential

enthalpy, the return air

enthalpy sensor may be

checked by connecting a

DC multi-meter or

voltmeter between

terminal S

R

of the W7459

and terminal S of the

return air enthalpy

sensor. (Position meter

lead to terminal S of

return air enthalpy

sensor.

Multi-meter or voltmeter

should indicate between

3 and 25 mA, if sensor

is operating properly.

If multi-meter or

voltmeter indicates

zero, the sensor may be

wired backwards.

Abbreviations

The following table lists the abbreviations found within this

document.

Abbrev.

Term

A

Ampere

BTU

British Thermal Units

DC

Direct Current

LED

Light Emitting Diode

mA

Milliampere

NTC

Negative temperature coefficient

RH

Relative Humidity

spdt

Single-pole, double -throw

spst

Single-pole, single-throw

Vac

Volts Alternating Current

Vdc

Volts Direct Current